Durable Stub Ends Designed For Use With Lap Joint Flanges In Pipelines

Lap joint stub ends provide flexibility, corrosion resistance, and cost savings when paired with lap joint flanges in piping systems.

Durable Stub Ends Designed For Use With Lap Joint Flanges In Pipelines

Lap joint stub ends provide flexibility, corrosion resistance, and cost savings when paired with lap joint flanges in piping systems.

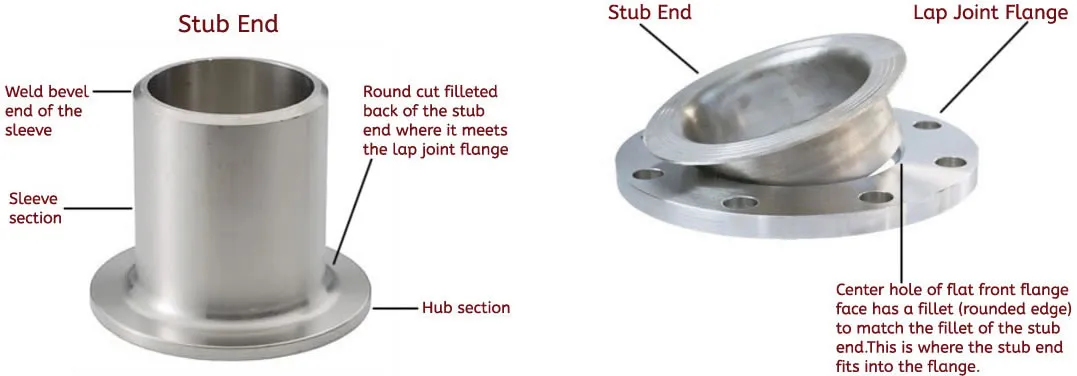

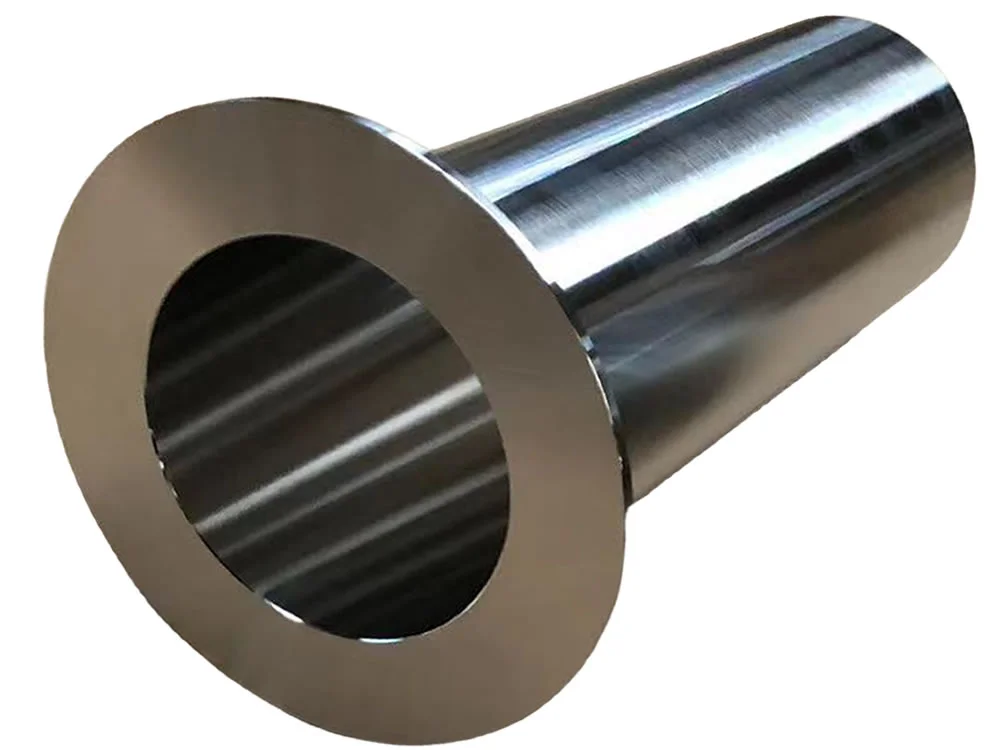

Lap Joint Stub Ends are specialized pipe fittings designed to be used with lap joint flanges, offering a flexible and cost-effective method of flange connection in industrial piping systems. Unlike welded flanges, the stub end is welded to the pipe while the loose lap joint flange can rotate freely, making alignment during installation much easier.

Stub ends are manufactured in accordance with ASME B16.9 and MSS-SP-43 standards, available in both short pattern and long pattern designs. They are produced from a wide range of materials including stainless steel, carbon steel, and alloy steel, depending on the service conditions and media being transported. This flexibility makes lap joint stub ends suitable for chemical processing plants, oil refineries, boiler systems, and power generation facilities.

The lap joint design minimizes stress on the welded joint, reduces wear, and allows for repeated disassembly without damaging the flange or pipe. This makes it especially advantageous for large-diameter or expensive alloy pipelines where only the flange ring requires a costly material, while the stub end itself can be produced from a more economical grade.

Available in sizes from 1/2” to 48” (DN15 to DN1200) and pressure ratings from 150# to 2500#, lap joint stub ends provide excellent corrosion resistance and mechanical strength. Surface finishes such as pickling, passivation, or hot-dip galvanizing are applied to enhance performance in aggressive environments. Each stub end undergoes rigorous testing, including PMI, hydrostatic, and nondestructive inspections, to ensure compliance with international standards.

Compared with traditional welded flanges, lap joint stub ends lower installation costs, simplify alignment, and extend the service life of pipelines. They are widely recognized as an efficient and reliable piping solution in industries requiring frequent maintenance, inspection, or modification.

Lap joint stub end is a fitting that is used replace welded flanges when the support of a rotating back up flange is required. And It can be supplied in standard and non-standard ANSI dimension that is used for connecting pipes of different diameter.

A stub end is always used with a lap joint flange as a backing flange. There are three different types of stub ends, type A, B and C. Type A stub end can be machined to fit the standard lap joint support flange. Type B stub end is designed to be used with standard slip on flange.

The main function of stub end is to connect pipes together in a piping system along with a stainless steel lap joint flange/backing flange. The stainless steel stub ends are used in conjunction with stainless steel lap joint flanges/backing flanges.

| Feature | A403 WPS304L Stub End | A234 WPB Stub End | A403 WPS304L Tee |

|---|---|---|---|

| Material Type | Stainless Steel (304L) | Carbon Steel | Stainless Steel (304L) |

| Temperature Range | Low to Moderate (up to 425°C) | Moderate (up to 650°C) | Low to Moderate (up to 425°C) |

| Corrosion Protection | Excellent (inherent) | Good (with coatings) | Excellent (inherent) |

| Pigging Compatibility | Poor (no bars) | Poor (no bars) | Poor (no bars) |

| Function | Flanged connection | Flanged connection | 90-degree branch |

| Applications | Chemical, Food, Marine, Boilers | Oil/Gas, Petrochemical, Boilers | Chemical, Food, Marine, Boilers |

| Tensile Strength (MPa) | 485 (min) | 415 (min) | 485 (min) |

| Yield Strength (MPa) | 170 (min) | 240 (min) | 170 (min) |

| Key Advantage | Superior corrosion resistance | Cost-effective flanged joints | Uniform pipe branching |

A403 WPS304L Stub End is widely used in chemical, food & beverage, water treatment, petrochemical, and pharmaceutical industries, ensuring leak-proof and reliable joints.

Quick removal of piping sections without disturbing the entire system for maintenance and inspection.

Use expensive materials only where needed, with cheaper backing flanges reducing overall cost.

Rotating backing flange allows easy alignment of bolt holes during installation.

Properly welded and assembled stub ends provide secure and leak-proof joints.

Compatible with various flange types and available in wide range of materials and sizes.

Manufactured to strict international standards with comprehensive testing and inspection.

Description: Produced and machined specifically to fit lap joint flanges.

Description: Suited for standard slip-on flanges acting as lap-joint flanges.

Description: Versatile for both lap joint and slip-on backing flanges.

Description: Similar to Type "C" with concentric serrations on lap face.

Longer length for easier alignment and welding. Suitable for frequent disassembly applications.

Standard Lap Joint FlangesSimilar length to pipe. Ideal for space-limited applications where flange needs to be close to pipe end.

Slip-On FlangesIn piping systems, a stub end is a crucial component used for connecting pipes of different materials and sizes. It provides a convenient and cost-effective solution for achieving a leak-free joint without the need for welding. In this article, we will explore the geometry, types, and applications of stub ends, shedding light on their significance in various industries and projects.

| N.D. | Out diameter | Hight(F) | Stub end O.D.(G) | Beveld radio(R) | ||||

|---|---|---|---|---|---|---|---|---|

| NPS | DN | OD | Mss | ANSI | Nominal&max | Nominal&min | A Max | B Max |

| 1/2 | 15 | 21.3 | 50.8 | 76.2 | 35 | 34 | 3 | 0.8 |

| 3/4 | 20 | 26.7 | 50.8 | 76.2 | 43 | 42 | 3 | 0.8 |

| 1 | 25 | 33.4 | 50.8 | 101.6 | 51 | 50 | 3 | 0.8 |

| 1 1/4 | 32 | 42.4 | 50.8 | 101.6 | 64 | 63 | 4.8 | 0.8 |

| 1 1/2 | 40 | 48.3 | 50.8 | 101.6 | 73 | 72 | 6.4 | 0.8 |

| 2 | 50 | 60.3 | 63.5 | 152.4 | 92 | 91 | 7.9 | 0.8 |

| 2 1/2 | 65 | 73 | 63.5 | 152.4 | 105 | 104 | 7.9 | 0.8 |

| 3 | 80 | 88.9 | 63.5 | 152.4 | 127 | 126 | 9.6 | 0.8 |

| 3 1/2 | 90 | 101.6 | 76.2 | 152.4 | 140 | 139 | 9.6 | 0.8 |

| 4 | 100 | 114.3 | 76.2 | 152.4 | 157 | 156 | 11.2 | 0.8 |

| 5 | 125 | 141.3 | 76.2 | 203.2 | 186 | 185 | 11.2 | 1.6 |

| 6 | 150 | 168.3 | 88.9 | 203.2 | 216 | 215 | 12.7 | 1.6 |

| 8 | 200 | 219.1 | 101.6 | 203.2 | 270 | 269 | 12.7 | 1.6 |

| 10 | 250 | 273.1 | 127 | 254 | 324 | 322 | 12.7 | 1.6 |

| 12 | 300 | 323.9 | 152.4 | 254 | 381 | 379 | 12.7 | 1.6 |

| 14 | 350 | 355.6 | 152.4 | 304.8 | 413 | 411 | 12.7 | 1.6 |

| 16 | 400 | 406.4 | 152.4 | 304.8 | 470 | 468 | 12.7 | 1.6 |

| 18 | 450 | 457.2 | 152.4 | 304.8 | 533 | 531 | 12.7 | 1.6 |

| 20 | 500 | 508 | 152.4 | 304.8 | 584 | 582 | 12.7 | 1.6 |

| 22 | 550 | 559 | 152.4 | 304.8 | 641 | 639 | 12.7 | 1.6 |

| 24 | 600 | 610 | 152.4 | 304.8 | 692 | 690 | 12.7 | 1.6 |

The following information shall be provided to order a stub end:

Stub ends can be ordered with different ends finishing:

| Material Type | Standards & Grades | Characteristics | Applications |

|---|---|---|---|

| Carbon Steel | ASTM A234 WPB, A420 WPL6 | High strength, cost-effective, good weldability | General industrial piping, oil & gas, power generation |

| Stainless Steel | ASTM A403 WP304/304L, WP316/316L | Excellent corrosion resistance, hygienic properties | Chemical processing, food & beverage, pharmaceutical |

| Alloy Steel | ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 | Enhanced strength, high-temperature resistance | High-temperature and high-pressure services |

Butt Weld Fittings

Stainless Steel Fittings

Buttwelding Ends

Japanese Standards

The Lap Joint Stub End allows sections pipe to be opened for inspection, cleaning or replacement without the need for additional welding.

Carbon steel stub ends provide durable, corrosion-...

Stainless steel stub ends provide superior corrosi...

The a403 wps304l stainless stub end is a pipe fitt...

Pipe saddle fittings provide safe and economical s...

Asme b16.9 stub ends are used with lap joint flang...

Pipe collar is a pipe fitting used in industrial p...