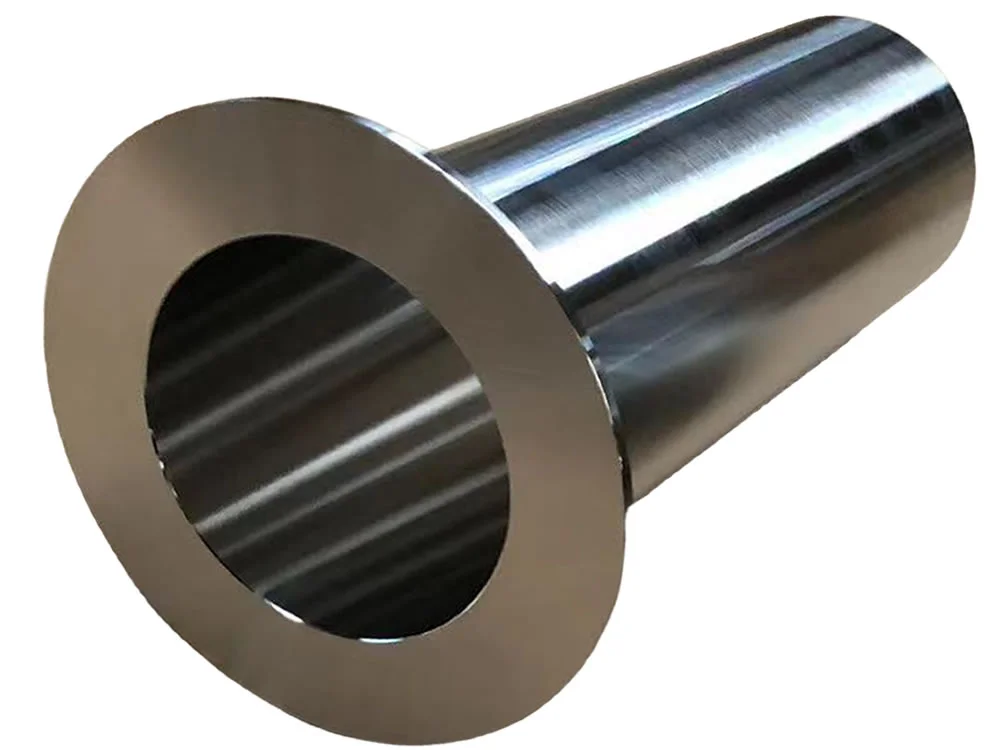

Corrosion-resistant Stainless Steel Stub Ends For Lap Joint Flange Connections

Stainless steel stub ends provide superior corrosion resistance, strength, and easy installation for lap joint flange connections in piping systems.

Corrosion-resistant Stainless Steel Stub Ends For Lap Joint Flange Connections

Stainless steel stub ends provide superior corrosion resistance, strength, and easy installation for lap joint flange connections in piping systems.

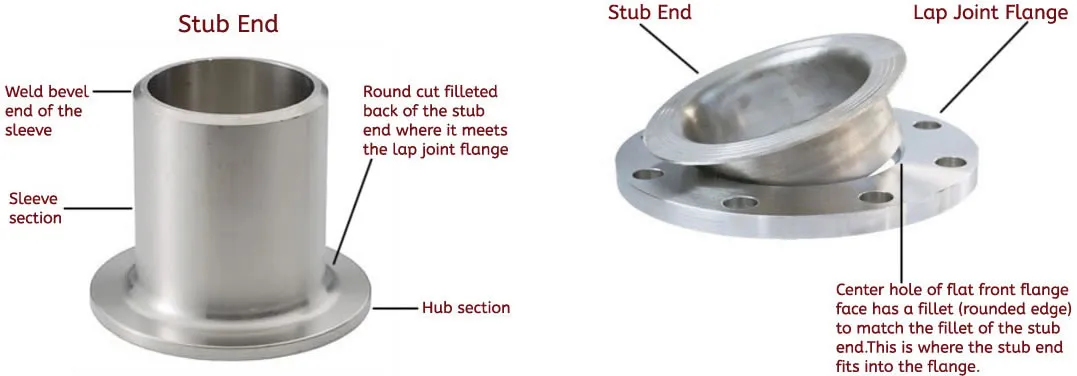

Stainless Steel Stub Ends are essential components used with lap joint flanges, providing a durable, corrosion-resistant, and easily alignable solution for piping systems. The stub end is welded to the pipe, while the lap joint flange remains loose, allowing flexibility in installation and frequent dismantling without damaging the pipeline.

Manufactured in accordance with ASME B16.9 and MSS-SP-43 standards, stainless steel stub ends are available in both short pattern and long pattern. They are typically produced from ASTM A403 WP304/304L, A403 WP316/316L, and other stainless grades, which deliver outstanding corrosion resistance, oxidation resistance, and mechanical strength.

Stub ends made of stainless steel are especially suitable for chemical plants, oil refineries, pharmaceutical facilities, water treatment systems, and food processing industries, where cleanliness and resistance to aggressive media are critical. Their surface can be treated by pickling, passivation, or electropolishing to further enhance performance.

Available in sizes from 1/2” to 48” (DN15–DN1200) and pressure ratings from 150# to 2500#, stainless steel stub ends provide long service life and low maintenance requirements. Their lap joint design reduces alignment difficulties and installation costs while extending pipeline efficiency.

Compared with carbon steel stub ends, stainless steel stub ends offer longer durability, higher resistance to temperature extremes, and protection against corrosion and chemical attack, making them a preferred choice in demanding industries.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08 max (WP304), 0.03 max (WP316L) |

| Manganese (Mn) | 2.00 max |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.03 max |

| Silicon (Si) | 0.75 max |

| Chromium (Cr) | 18.0-20.0 (WP304), 16.0-18.0 (WP316L) |

| Nickel (Ni) | 8.0-11.0 (WP304), 10.0-14.0 (WP316L) |

| Molybdenum (Mo) | - (WP304), 2.0-3.0 (WP316L) |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 515 (WP304), 485 (WP316L) |

| Yield Strength, min (MPa) | 205 (WP304), 170 (WP316L) |

| Elongation, min (%) | 40 (WP304), 35 (WP316L) |

| Hardness, max (HBW) | 201 (WP304), 217 (WP316L) |

| Feature | ASTM A403 WP304 (Stainless) | ASTM A234 WPB (Carbon Steel) | ASTM A815 UNS S31803 (Duplex) |

|---|---|---|---|

| Material Type | Stainless Steel | Carbon Steel | Duplex Stainless Steel |

| Temperature Range | Up to 870°C | Up to 427°C | Up to 600°C |

| Corrosion Resistance | Excellent | Moderate (With coatings) | Superior (Pitting resistance) |

| Applications | Chemical, food processing | Boilers, general piping | Oil/gas, marine |

| Tensile Strength (MPa) | 515 (min) | 415 (min) | 620 (min) |

| Yield Strength (MPa) | 205 (min) | 240 (min) | 450 (min) |

| Key Advantage | High corrosion resistance | Cost-effective | High strength, corrosion resistance |

A curated list of long-tail keywords for stainless steel stub ends, covering specifications, applications, and material properties, presented in a two-column layout.

Note: Stainless steel stub ends comply with ASME B16.9 and ASTM A403 standards. For detailed specifications, refer to the relevant standards or contact a certified supplier.

Quick removal of piping sections without disturbing the entire system for maintenance and inspection.

Use expensive materials only where needed, with cheaper backing flanges reducing overall cost.

Rotating backing flange allows easy alignment of bolt holes during installation.

Properly welded and assembled stub ends provide secure and leak-proof joints.

Compatible with various flange types and available in wide range of materials and sizes.

Manufactured to strict international standards with comprehensive testing and inspection.

Description: Produced and machined specifically to fit lap joint flanges.

Description: Suited for standard slip-on flanges acting as lap-joint flanges.

Description: Versatile for both lap joint and slip-on backing flanges.

Description: Similar to Type "C" with concentric serrations on lap face.

Longer length for easier alignment and welding. Suitable for frequent disassembly applications.

Standard Lap Joint FlangesSimilar length to pipe. Ideal for space-limited applications where flange needs to be close to pipe end.

Slip-On FlangesIn piping systems, a stub end is a crucial component used for connecting pipes of different materials and sizes. It provides a convenient and cost-effective solution for achieving a leak-free joint without the need for welding. In this article, we will explore the geometry, types, and applications of stub ends, shedding light on their significance in various industries and projects.

| N.D. | Out diameter | Hight(F) | Stub end O.D.(G) | Beveld radio(R) | ||||

|---|---|---|---|---|---|---|---|---|

| NPS | DN | OD | Mss | ANSI | Nominal&max | Nominal&min | A Max | B Max |

| 1/2 | 15 | 21.3 | 50.8 | 76.2 | 35 | 34 | 3 | 0.8 |

| 3/4 | 20 | 26.7 | 50.8 | 76.2 | 43 | 42 | 3 | 0.8 |

| 1 | 25 | 33.4 | 50.8 | 101.6 | 51 | 50 | 3 | 0.8 |

| 1 1/4 | 32 | 42.4 | 50.8 | 101.6 | 64 | 63 | 4.8 | 0.8 |

| 1 1/2 | 40 | 48.3 | 50.8 | 101.6 | 73 | 72 | 6.4 | 0.8 |

| 2 | 50 | 60.3 | 63.5 | 152.4 | 92 | 91 | 7.9 | 0.8 |

| 2 1/2 | 65 | 73 | 63.5 | 152.4 | 105 | 104 | 7.9 | 0.8 |

| 3 | 80 | 88.9 | 63.5 | 152.4 | 127 | 126 | 9.6 | 0.8 |

| 3 1/2 | 90 | 101.6 | 76.2 | 152.4 | 140 | 139 | 9.6 | 0.8 |

| 4 | 100 | 114.3 | 76.2 | 152.4 | 157 | 156 | 11.2 | 0.8 |

| 5 | 125 | 141.3 | 76.2 | 203.2 | 186 | 185 | 11.2 | 1.6 |

| 6 | 150 | 168.3 | 88.9 | 203.2 | 216 | 215 | 12.7 | 1.6 |

| 8 | 200 | 219.1 | 101.6 | 203.2 | 270 | 269 | 12.7 | 1.6 |

| 10 | 250 | 273.1 | 127 | 254 | 324 | 322 | 12.7 | 1.6 |

| 12 | 300 | 323.9 | 152.4 | 254 | 381 | 379 | 12.7 | 1.6 |

| 14 | 350 | 355.6 | 152.4 | 304.8 | 413 | 411 | 12.7 | 1.6 |

| 16 | 400 | 406.4 | 152.4 | 304.8 | 470 | 468 | 12.7 | 1.6 |

| 18 | 450 | 457.2 | 152.4 | 304.8 | 533 | 531 | 12.7 | 1.6 |

| 20 | 500 | 508 | 152.4 | 304.8 | 584 | 582 | 12.7 | 1.6 |

| 22 | 550 | 559 | 152.4 | 304.8 | 641 | 639 | 12.7 | 1.6 |

| 24 | 600 | 610 | 152.4 | 304.8 | 692 | 690 | 12.7 | 1.6 |

The following information shall be provided to order a stub end:

Stub ends can be ordered with different ends finishing:

| Material Type | Standards & Grades | Characteristics | Applications |

|---|---|---|---|

| Carbon Steel | ASTM A234 WPB, A420 WPL6 | High strength, cost-effective, good weldability | General industrial piping, oil & gas, power generation |

| Stainless Steel | ASTM A403 WP304/304L, WP316/316L | Excellent corrosion resistance, hygienic properties | Chemical processing, food & beverage, pharmaceutical |

| Alloy Steel | ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 | Enhanced strength, high-temperature resistance | High-temperature and high-pressure services |

Butt Weld Fittings

Stainless Steel Fittings

Buttwelding Ends

Japanese Standards

The Stainless Stub End allows sections pipe to be opened for inspection, cleaning or replacement without the need for additional welding.

Carbon steel stub ends provide durable, corrosion-...

Lap joint stub ends provide flexibility, corrosion...

The a403 wps304l stainless stub end is a pipe fitt...

Pipe saddle fittings provide safe and economical s...

Asme b16.9 stub ends are used with lap joint flang...

Pipe collar is a pipe fitting used in industrial p...