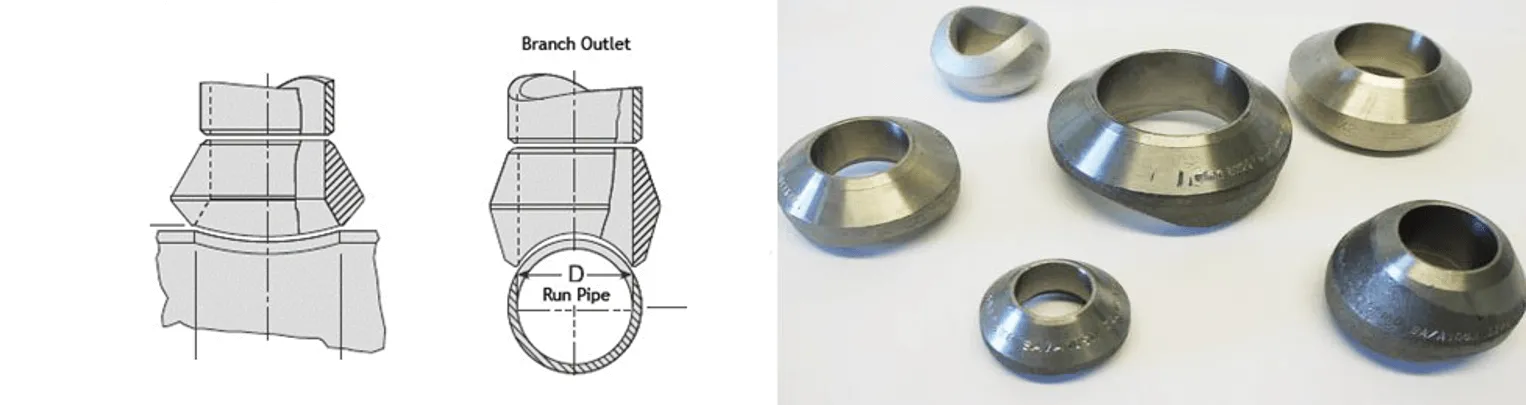

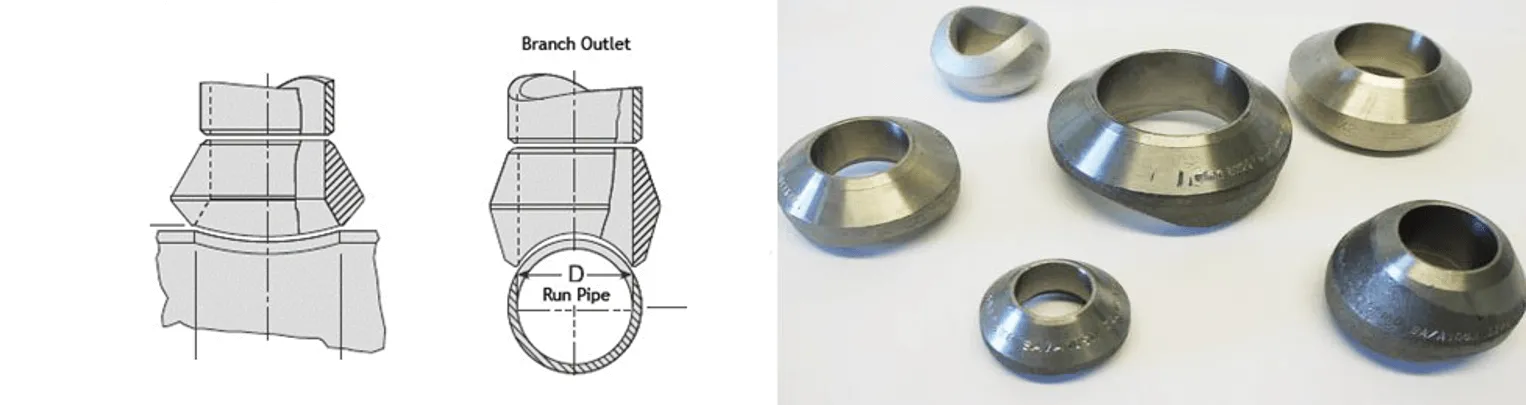

Weldolet dimensions

Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends.

Fittings manufactured to this Standard Practice are designed to make a fully reinforced branch connection in accordance with applicable piping code requirements, when attached, at an opening in a run pipe by means of a full penetration weld.

This classification refers to its beveled outlet that is butt-welded to the branch pipe during installation. The weldolet is ideal for replacing a tee on 90-degree branches with a reinforced connection that protects the branch pipe by reducing stress concentration due to its shape and size.

Pressure Rating Specifications

| pressure |

NPS |

A |

B |

C |

D |

| STD |

1/2″ |

19.05 |

34.93 |

23.81 |

15.88 |

| STD |

3/4″ |

22.23 |

41.28 |

30.16 |

20.64 |

| STD |

1″ |

26.99 |

50.8 |

36.51 |

26.19 |

| STD |

1 1/4″ |

31.75 |

60.3 |

44.45 |

34.93 |

| STD |

1 1/2″ |

33.34 |

73 |

50.8 |

41.28 |

| STD |

2″ |

38.1 |

88.9 |

65.09 |

52.39 |

| STD |

2 1/2″ |

41.28 |

103.19 |

76.2 |

61.91 |

| STD |

3″ |

44.45 |

122.24 |

93.66 |

77.79 |

| STD |

3 1/2″ |

50.8 |

136.53 |

98.43 |

90.49 |

| STD |

4″ |

50.8 |

152.4 |

120.65 |

101.6 |

| STD |

5″ |

57.15 |

180.98 |

141.29 |

128.59 |

| STD |

6″ |

60.3 |

215.9 |

169.86 |

153.99 |

| STD |

8″ |

69.85 |

263.53 |

220.66 |

201.61 |

| STD |

10″ |

77.79 |

319.09 |

274.64 |

254 |

| STD |

12″ |

85.73 |

377.83 |

325.44 |

304.8 |

| STD |

14″ |

88.9 |

409.58 |

357.19 |

336.55 |

| STD |

16″ |

93.66 |

463.55 |

407.99 |

387.35 |

| STD |

18″ |

103.19 |

527.05 |

473.08 |

438.15 |

| STD |

20″ |

117.48 |

585.79 |

509.59 |

488.95 |

| STD |

24″ |

136.53 |

708.03 |

638.18 |

590.55 |

| XS |

1/2″ |

19.05 |

34.93 |

23.81 |

15.88 |

| XS |

3/4″ |

22.23 |

41.28 |

30.16 |

20.64 |

| XS |

1″ |

26.99 |

50.8 |

36.51 |

26.19 |

| XS |

1 1/4″ |

31.75 |

61.91 |

44.45 |

34.93 |

| XS |

1 1/2″ |

33.34 |

73 |

50.8 |

41.28 |

| XS |

2″ |

38.1 |

88.9 |

65.09 |

52.39 |

| XS |

2 1/2″ |

41.28 |

103.19 |

76.2 |

61.91 |

| XS |

3″ |

44.45 |

122.24 |

93.66 |

77.79 |

| XS |

3 1/2″ |

50.8 |

136.53 |

98.43 |

90.49 |

| XS |

4″ |

50.8 |

152.4 |

120.65 |

101.6 |

| XS |

5″ |

57.15 |

180.98 |

141.29 |

128.59 |

| XS |

6″ |

77.79 |

225.43 |

169.86 |

153.99 |

| XS |

8″ |

98.43 |

269.88 |

220.66 |

193.68 |

| XS |

10″ |

88.9 |

327.03 |

265.11 |

254 |

| XS |

12″ |

100.01 |

385.76 |

330.2 |

304.8 |

| XS |

14″ |

104.78 |

423.86 |

363.54 |

330.2 |

| XS |

16″ |

112.71 |

479.43 |

419.1 |

381 |

| XS |

18″ |

119.06 |

536.58 |

473.08 |

431.8 |

| XS |

20″ |

127 |

593.73 |

528.64 |

482.6 |

| XS |

24″ |

139.7 |

708.03 |

638.18 |

584.2 |

Fittings may be made to special dimensions, size, shape, tolerances, or of other wrought material by agreement between the manufacturer and the purchaser.

Weldolets are specialized branch connection fittings designed to create robust, leak-free

connections in industrial piping systems. Conforming to standards such as MSS SP-97, ASME

B31.3, and ASTM specifications, weldolets are engineered for high-performance applications, including

boiler pipeline protection, oil and gas pipelines, chemical processing, and power

generation. Their welded design ensures exceptional corrosion resistance and structural

integrity, making them ideal for demanding environments requiring reliable branch connections.

Manufactured from materials like carbon steel (ASTM A105, A234 WPB), stainless steel (ASTM A182 F304/316L),

or alloy steel, weldolets are produced through forging or machining processes to ensure

high strength and precision. These fittings are welded directly onto the main pipe, providing a strong,

permanent branch connection without compromising the pipeline’s integrity. Available in sizes from 1/2” to

24” (DN15 to DN600) for the branch and compatible with main pipes up to 48” (DN1200), weldolets come in

schedules from SCH 10 to XXS. Surface treatments like galvanizing, 3LPE, or passivation enhance

corrosion resistance, ensuring durability in harsh environments such as petrochemical

plants and marine applications.

Welded branch fittings like weldolets undergo stringent testing, including hydrostatic,

ultrasonic, and radiographic inspections, to ensure weld quality and compliance with MSS SP-97 and ASME

standards. With tensile strengths ranging from 415 MPa (carbon steel) to 515 MPa (stainless steel),

weldolets provide reliable performance in systems handling high-pressure fluids, corrosive gases, or

abrasive materials. Their contoured design ensures a smooth transition of flow, minimizing turbulence and

pressure loss, making them ideal for industrial piping systems where efficiency and

durability are critical.

The primary advantage of weldolets lies in their ability to create strong, compact branch

connections with minimal welding, reducing installation time and costs compared to traditional tees or

fabricated branches. Their reinforced design provides superior strength at the branch point, making them

suitable for high-pressure and high-temperature applications, such as in boiler pipeline

protection. Weldolets are particularly effective in retrofitting existing pipelines or adding

branches in confined spaces, offering flexibility for complex piping layouts in refineries, chemical plants,

and power generation facilities.

Weldolets address critical challenges like pipeline corrosion, pressure loss, and complex

branching in industrial systems. Their robust construction, compliance with strict standards, and material

versatility make them a preferred choice for engineers seeking durable pipe connections.

Whether used in high-temperature boiler systems, corrosive petrochemical environments, or hygienic food

processing lines, weldolets deliver unmatched performance, safety, and longevity.

A weldolet, also called welding outlet, is a way of connecting a welded connection that is contoured at the

bottom to match the contour of the pipe. So one end of the welding outlet is welded on the pipe, whereas the

other end is open to be welded to any other pipe or equipment. A welding outlet requires mentioning the size

of out let and the "Run Size" of pipe so the contour can match the contour of the pipe. The size of the

welding outlet will always be smaller than run size such as 1/2" welding outlet can be used on pipe (run

size) 1/2" and bigger.

Chemical Composition of ASME B16.9 Stub Ends

| Element |

Composition (%) |

| Carbon (C) |

0.30 max (WPB), 0.08 max (WP304) |

| Manganese (Mn) |

0.29-1.06 (WPB), 2.00 max (WP304) |

| Phosphorus (P) |

0.05 max (WPB), 0.045 max (WP304) |

| Sulfur (S) |

0.058 max (WPB), 0.03 max (WP304) |

| Silicon (Si) |

0.10 min (WPB), 0.75 max (WP304) |

| Chromium (Cr) |

- (WPB), 18.0-20.0 (WP304) |

| Nickel (Ni) |

- (WPB), 8.0-11.0 (WP304) |

Mechanical Properties of ASME B16.9 Stub Ends

| Property |

Value |

| Tensile Strength, min (MPa) |

415 (WPB), 515 (WP304) |

| Yield Strength, min (MPa) |

240 (WPB), 205 (WP304) |

| Elongation, min (%) |

22 (WPB), 40 (WP304) |

| Hardness, max (HBW) |

197 (WPB), 201 (WP304) |

Comparison of ASME B16.9 Stub Ends with Other Fittings

| Feature |

ASME B16.9 Stub End |

ASME B16.9 Tee |

ASME B16.9 Reducer |

| Material Type |

Carbon/Stainless Steel |

Carbon/Stainless Steel |

Carbon/Stainless Steel |

| Connection Type |

Welded with Lap Joint |

Welded/Threaded |

Welded |

| Corrosion Resistance |

Excellent (Material-dependent) |

Excellent (Material-dependent) |

Excellent (Material-dependent) |

| Applications |

Flange connections, maintenance |

Branching, flow distribution |

Size transition |

| Tensile Strength (MPa) |

415-515 (min) |

415-515 (min) |

415-515 (min) |

| Installation Complexity |

Low (Flange alignment) |

Moderate (Pipe cutting) |

Low (Welded) |

| Key Advantage |

Easy maintenance, cost-effective |

Balanced flow distribution |

Seamless size transition |