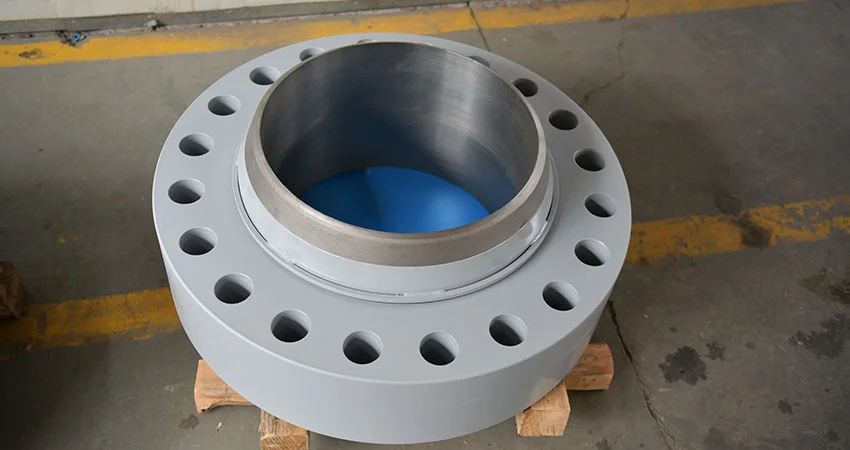

Swivel Ring Flange is a two-piece flange designed for industrial

piping systems, particularly in subsea and offshore applications, to facilitate easy bolt

alignment and ensure reliable connections. Complying with ASME B16.5, ASME B16.47, and API 17D

standards, it consists of a heavy forged welding hub and a rotating forged ring, secured by a retaining ring. Made

from materials like carbon steel (ASTM A105), stainless steel (A182 F316), or high-yield alloys (A694 F52-F70),

these flanges offer exceptional corrosion resistance, ideal for boiler pipeline

protection and harsh environments.

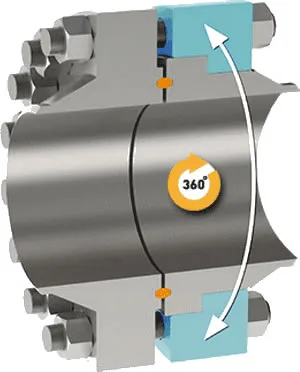

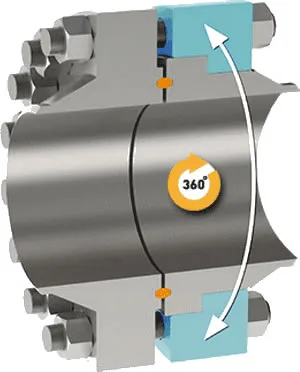

The swivel ring flange allows 360° rotation of the outer ring, simplifying bolt hole alignment

during installation, especially in challenging subsea conditions. Available in sizes from 1/2” to 60” and pressure

ratings from Class 150 to 2500, they support raised face (RF), flat face (FF), or ring-type joint (RTJ)

configurations. The design reduces installation time and labor costs, with surface treatments like 3LPE,

galvanizing, or PTFE coating enhancing corrosion resistance for handling corrosive fluids in oil

and gas or petrochemical applications.

These flanges undergo rigorous testing, including hydrostatic, tensile, and non-destructive tests (ultrasonic,

radiographic), to meet ASME and API standards. With minimum tensile strengths of 485 MPa (A105) to 550 MPa (A694

F65), they withstand high-pressure conditions up to 10,000 psi and temperatures from -29°C to 425°C. The swivel

mechanism minimizes stress on the pipeline, making them suitable for subsea pipeline installations,

where precise alignment is critical, and for boiler pipeline protection in power plants and

refineries.

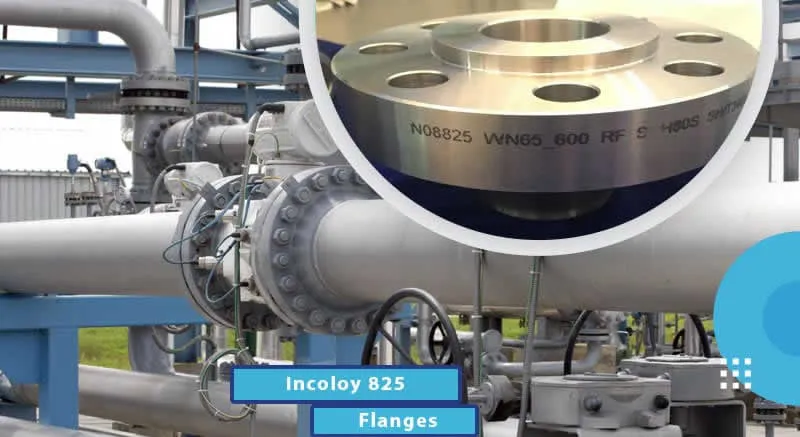

Compared to standard weld neck flanges, swivel ring flanges offer superior flexibility for bolt

alignment, reducing the need for complex adjustments. They are comparable to a stub end and lap joint flange but are

engineered for higher-pressure applications, particularly in offshore piping. Their robust construction and ability

to handle large movements make them ideal for dynamic systems, including marine, chemical processing, and LNG

terminals, where corrosion resistance and durability are paramount.

Swivel ring flanges address challenges like pipeline misalignment, thermal stress, and corrosion in

demanding industrial environments. Their innovative design and material versatility make them a preferred choice for

engineers seeking reliable solutions for industrial piping. Whether used in subsea pipelines or

high-pressure boiler systems, these flanges deliver unmatched performance, safety, and longevity.

What is a Swivel Ring Flange?

The Swivel Ring Flange is comparable to a set of stub end and lap joint flange, with the difference that an Swivel Ring Flange is used for higher pressure and mostly in offshore / subsea applications.

The swivel ring flanges adjust for bolt hole misalignment in the field via rotational adjustment of the bolt hole pattern on the flange ring relative to the spool piece.

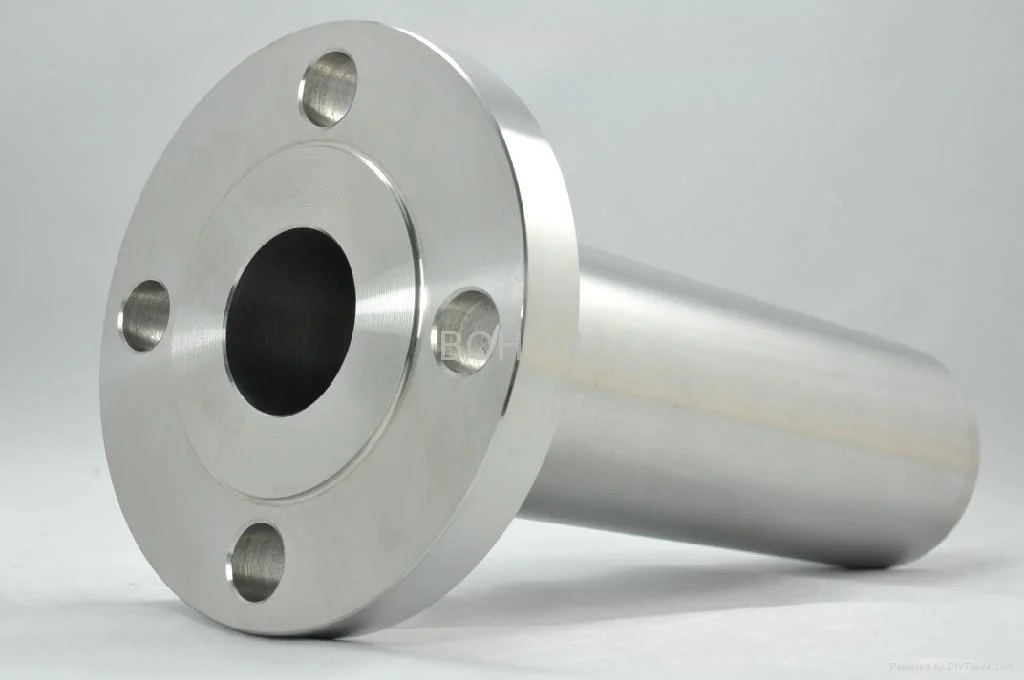

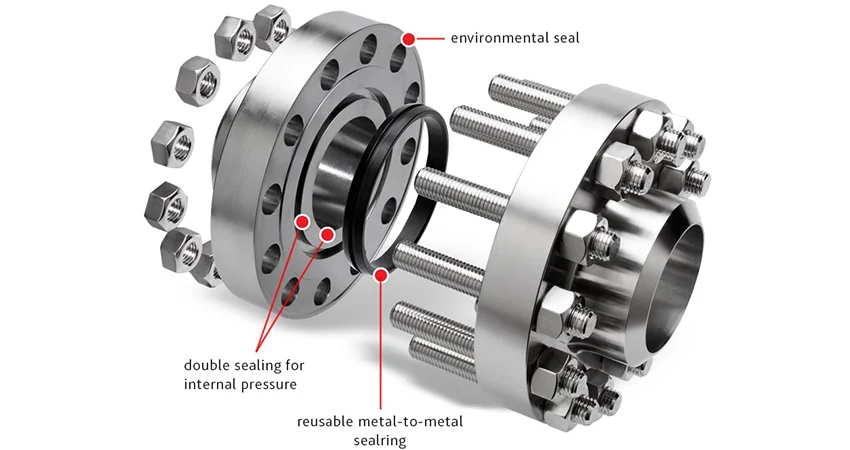

The Swivel Ring Flange is of two piece construction consisting of a heavy forged welding hub with a rotating forged ring that serves as a mating flange to a Weld Neck or other flange. It has a Retaining Ring to secure the Welding Hub to hold the Rotating Ring in position.

These versatile flanges are utilized in many applications and are used extensively in offshore piping where they solve the issues associated with the alignment of bolt holes during subsea flange installation.

Ratings

Standard materials are A105 with a minimum yield of 42,000 psi and additional thickness is provided at the welding end to compensate for higher yield pipe. These flanges can be furnished in higher yield materials such as ASTM A694 or ASTM A707 and are also supplied to customer specifications.

Chemical Composition of Swivel Ring Flange

| Element |

ASTM A105 (%) |

ASTM A182 F316 (%) |

| Carbon (C) |

0.35 max |

0.08 max |

| Manganese (Mn) |

0.60-1.05 |

2.00 max |

| Phosphorus (P) |

0.035 max |

0.045 max |

| Sulfur (S) |

0.040 max |

0.03 max |

| Silicon (Si) |

0.10-0.35 |

0.75 max |

| Chromium (Cr) |

0.30 max |

16.0-18.0 |

| Nickel (Ni) |

0.40 max |

10.0-14.0 |

| Molybdenum (Mo) |

0.12 max |

2.0-3.0 |

Mechanical Properties of Swivel Ring Flange

| Property |

ASTM A105 |

ASTM A182 F316 |

| Tensile Strength, min (MPa) |

485 |

515 |

| Yield Strength, min (MPa) |

250 |

205 |

| Elongation, min (%) |

22 |

30 |

| Hardness, max (HBW) |

187 |

217 |