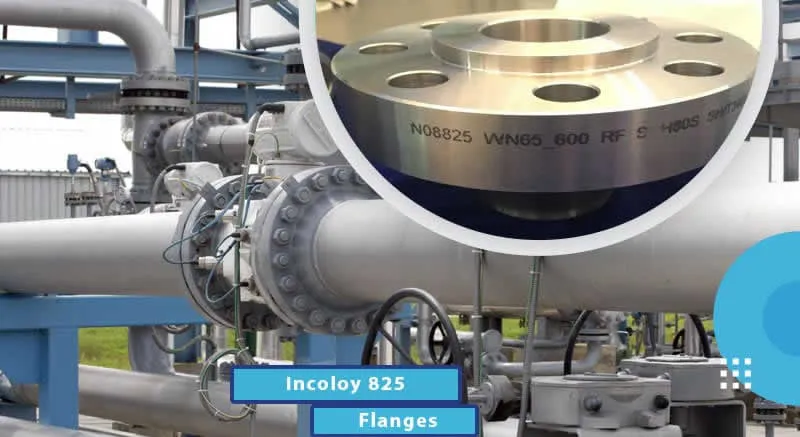

Compact Flange is an advanced, space-saving flange designed for industrial

piping systems requiring high-pressure and high-temperature performance. Compliant with standards like

NORSOK L-005 and ISO 27509, these flanges provide superior corrosion resistance and leak-proof

connections, making them ideal for boiler pipeline protection, offshore platforms, and subsea

applications. Constructed from materials such as carbon steel (ASTM A105), stainless steel (A182 F316L), or

high-yield alloys (A694 F60), they are engineered for durability in harsh environments like oil and gas,

petrochemical, and power generation industries.

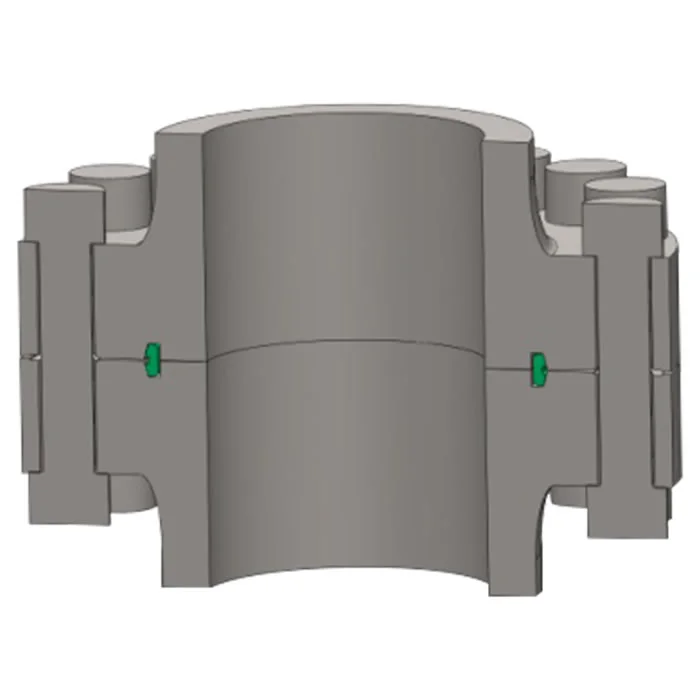

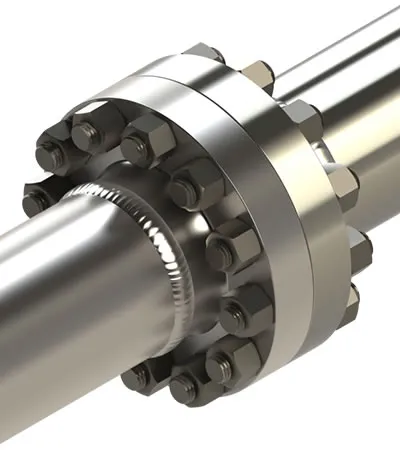

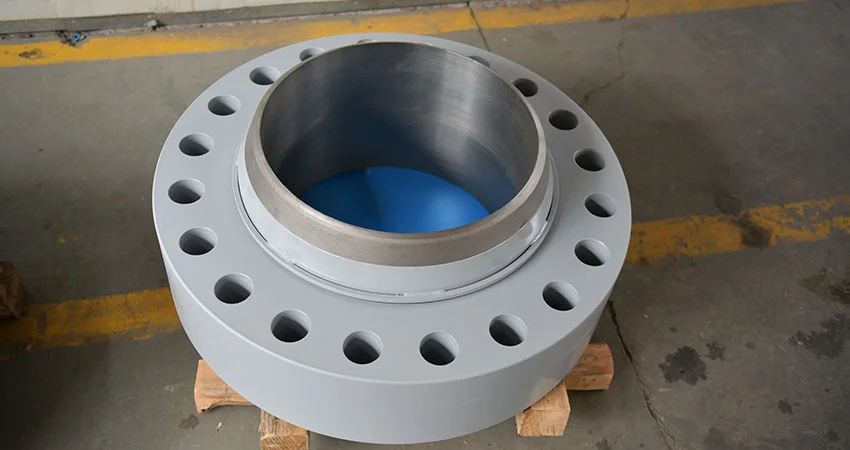

The compact flange features a unique design with a reduced diameter and fewer bolts compared to

traditional ASME B16.5 flanges, resulting in a lighter and more cost-effective solution. Available in sizes from

1/2” to 48” and pressure ratings up to 15,000 psi, they support ring-type joint (RTJ) or IX seal ring configurations

for enhanced sealing. Surface treatments like 3LPE, PTFE, or galvanizing further improve corrosion

resistance, ensuring reliability when handling corrosive fluids or gases in chemical processing or

marine systems.

These flanges undergo stringent testing, including hydrostatic, tensile, and non-destructive tests (ultrasonic,

radiographic), to ensure compliance with NORSOK and API standards. With tensile strengths ranging from 485 MPa

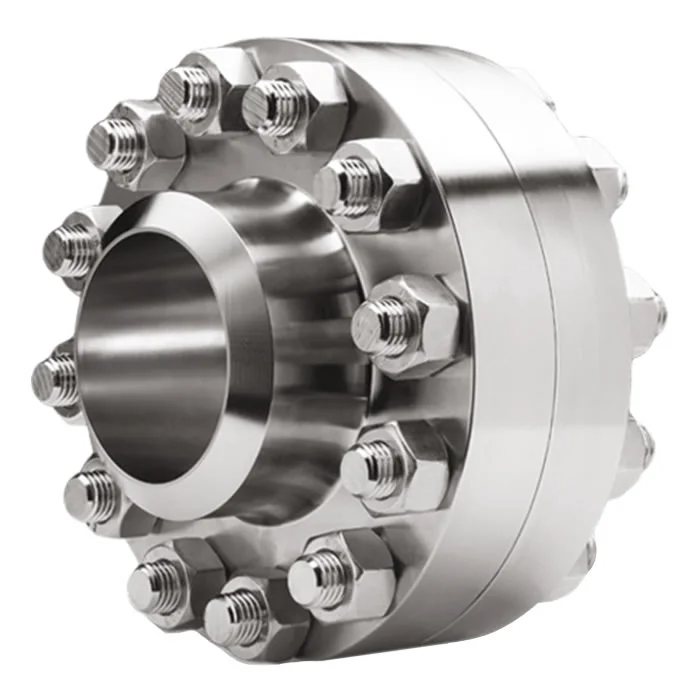

(A105) to 515 MPa (F316L), they excel in high-pressure conditions and temperatures from -29°C to 550°C. The compact

design minimizes weight and space requirements, making them suitable for high-pressure flange

applications in constrained environments like FPSO units or boiler pipeline protection in power

plants.

Compared to conventional weld neck or slip-on flanges, compact flanges offer significant advantages

in weight reduction (up to 80% lighter) and installation efficiency, reducing bolt torque requirements and

maintenance costs. Their robust sealing mechanism, often using metal-to-metal seals, ensures zero leakage, critical

for industrial piping systems handling hazardous media. They are particularly suited for subsea

pipelines, LNG terminals, and refineries where space, weight, and reliability are paramount.

Compact flanges address challenges like pipeline corrosion, thermal stress, and space constraints

in demanding industrial environments. Their innovative design, compliance with stringent standards, and material

versatility make them a preferred choice for engineers seeking reliable, space-saving flange

solutions. Whether used in high-pressure boiler systems or corrosive offshore applications, these flanges deliver

exceptional performance, safety, and longevity.

Chemical Composition of Compact Flange

| Element |

ASTM A105 (%) |

ASTM A182 F316L (%) |

| Carbon (C) |

0.35 max |

0.03 max |

| Manganese (Mn) |

0.60-1.05 |

2.00 max |

| Phosphorus (P) |

0.035 max |

0.045 max |

| Sulfur (S) |

0.040 max |

0.03 max |

| Silicon (Si) |

0.10-0.35 |

0.75 max |

| Chromium (Cr) |

0.30 max |

16.0-18.0 |

| Nickel (Ni) |

0.40 max |

10.0-14.0 |

| Molybdenum (Mo) |

0.12 max |

2.0-3.0 |

Mechanical Properties of Compact Flange

| Property |

ASTM A105 |

ASTM A182 F316L |

| Tensile Strength, min (MPa) |

485 |

515 |

| Yield Strength, min (MPa) |

250 |

205 |

| Elongation, min (%) |

22 |

30 |

| Hardness, max (HBW) |

187 |

217 |

Comparison of Compact Flange with Other Flanges

| Feature |

Compact Flange |

Weld Neck Flange |

Slip-On Flange |

| Material Type |

Carbon/Stainless Steel |

Carbon/Stainless Steel |

Carbon/Stainless Steel |

| Connection Type |

Butt Weld (Compact Design) |

Butt Weld |

Fillet Weld |

| Corrosion Resistance |

Excellent (Material-dependent) |

Excellent (Material-dependent) |

Moderate (Coatings needed) |

| Applications |

Subsea, Offshore, High-Pressure |

High-Pressure Pipelines |

Low-Pressure Systems |

| Tensile Strength (MPa) |

485-515 (min) |

485-515 (min) |

415-485 (min) |

| Weight |

Up to 80% lighter |

Standard |

Light |

| Key Advantage |

Space-saving, leak-proof |

Smooth stress distribution |

Cost-effective, easy install |

What is Compact Flange?

A lighter, stronger, and more reliable piping connection

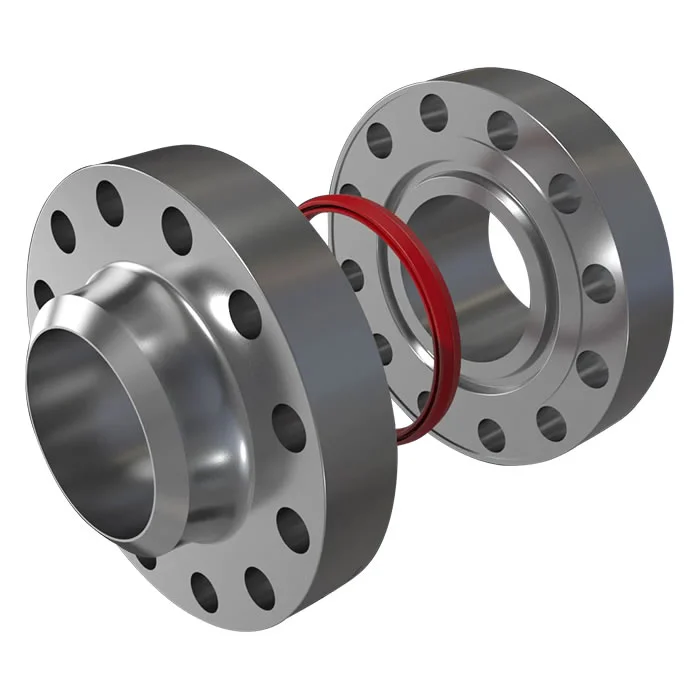

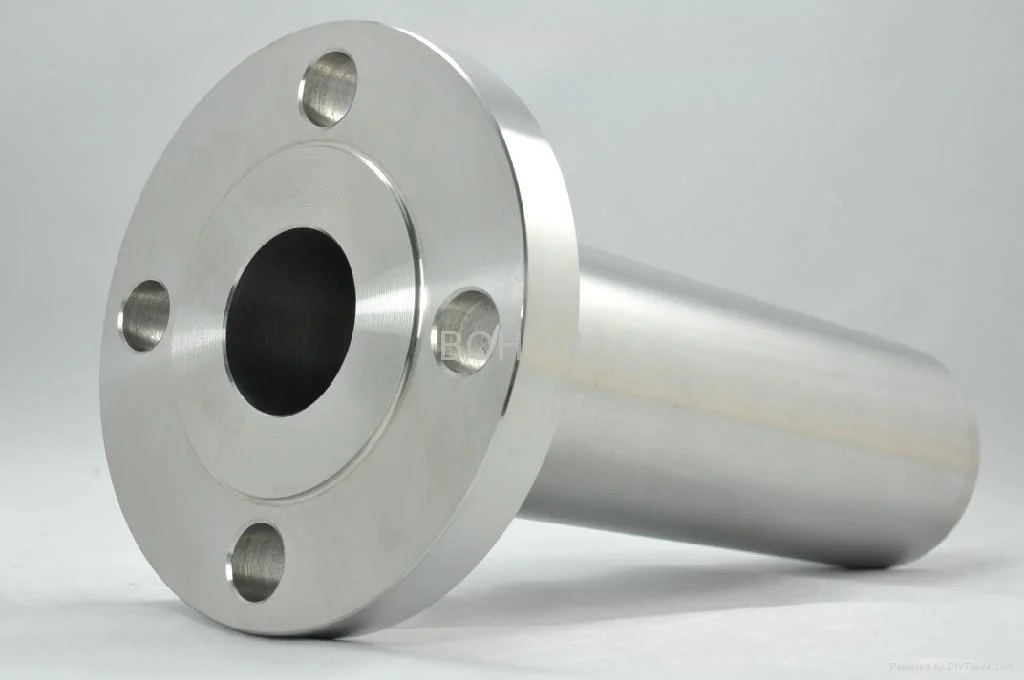

A compact flange—also called a Hubless Flange or Type C Flange—is engineered to deliver superior

strength and leak-tight performance while being much smaller and lighter than conventional flanges. Its low-profile design

makes it suitable for demanding applications where space and weight savings are critical.

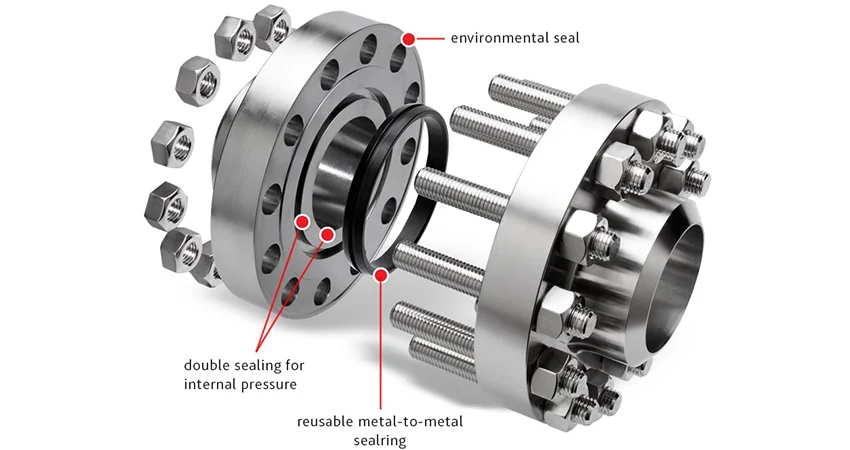

Structure and Components

- 🔹 Metal Seal Ring – Provides a tight, leak-proof seal between mating flanges.

- 🔹 Flange Body – Prevents seal deformation and distributes bolt load evenly.

- 🔹 Bolts – Ensure secure and reliable flange connections.

Advantages of Compact Flanges

⚡

Weight & Space Savings

Up to 70% lighter than traditional flanges, ideal for offshore and confined installations.

🔒

Leak-Tight Integrity

Double sealing ensures reliable performance even under high pressure and vibration.

⚙️

Durability

Excellent resistance to fatigue, thermal cycling, and harsh operating conditions.

Compact flanges provide leak-free joint integrity, environmental safety, and reduced installation costs,

making them one of the most effective piping joints for modern industry.