High-pressure Branch Connection For Hot Tapping Pipelines

Split tees provide robust, corrosion-resistant branch connections for hot tapping in industrial piping, ensuring durability and safety in boiler systems and petrochemical pipelines.

High-pressure Branch Connection For Hot Tapping Pipelines

Split tees provide robust, corrosion-resistant branch connections for hot tapping in industrial piping, ensuring durability and safety in boiler systems and petrochemical pipelines.

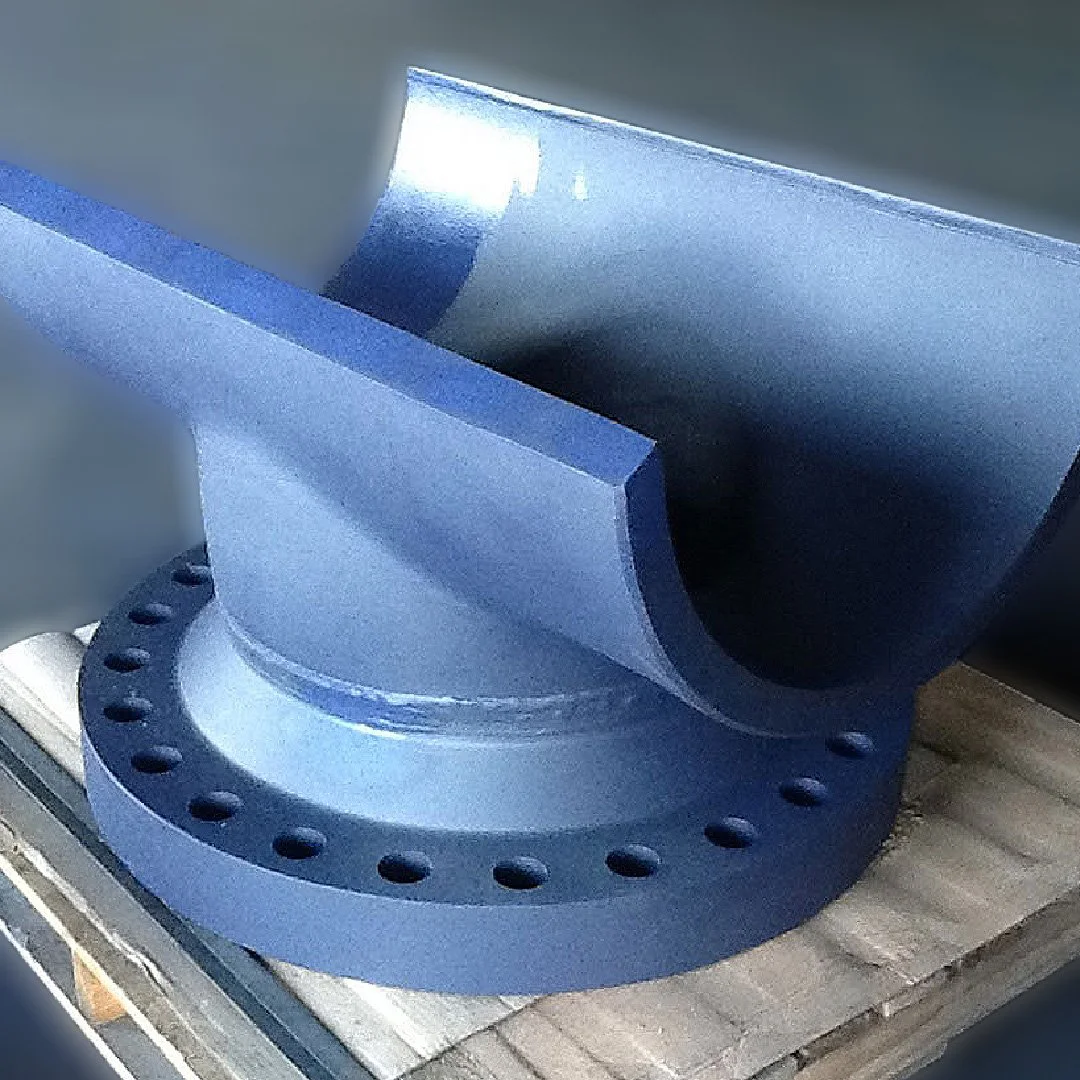

Split Tee, also known as a hot tapping tee, is a specialized pipe fitting designed to create branch connections on live pipelines without interrupting flow. Compliant with ASME B16.9 and ASME B16.25 standards, split tees provide exceptional corrosion resistance and strength for industrial piping systems. Made from materials like carbon steel (ASTM A234 WPB), stainless steel (ASTM A403 WP304/316L), or alloy steel (A234 WP11), they are suited for high-pressure and high-temperature applications in oil and gas, petrochemical, and power generation industries, ensuring reliable boiler pipeline protection.

The split tee features two symmetrical halves that encase the pipeline, secured by bolting or welding, enabling hot tapping or line-stop operations. This design eliminates external reinforcements, enhancing resistance to cyclic and thermal loads. Available in sizes from 2” to 60” (DN50 to DN1500) with wall thicknesses from SCH 40 to SCH 160, split tees can be customized with 3LPE or epoxy coatings for improved corrosion resistance. They withstand pressures up to 2500 psi and temperatures up to 600°C, making them ideal for pipeline wear solutions in demanding environments.

Split tees undergo stringent testing, including hydrostatic, ultrasonic, and weld inspections, to ensure compliance with industry standards. With tensile strengths of 415-585 MPa (A234 WPB) and yield strengths of 240 MPa, they offer robust performance in corrosive environments, such as those with hydrogen sulfide or acidic fluids. The seamless or welded construction ensures minimal flow disruption, and the hot tapping capability reduces downtime in critical systems like refineries and subsea pipelines.

Unlike standard tees, split tees are tailored for hot tapping, providing flexibility for retrofitting existing pipelines. Their corrosion resistance, enhanced by stainless steel or protective coatings, makes them suitable for harsh conditions. They support complex piping layouts with butt-weld, flanged, or threaded end connections, meeting diverse project needs.

Split tees address challenges like pipeline corrosion, wear, and operational continuity in high-throughput systems. Their robust design and hot tapping functionality make them a preferred choice for engineers seeking reliable industrial piping solutions for boiler pipeline protection and other critical applications.

| Element | ASTM A234 WPB (%) | ASTM A403 WP316L (%) |

|---|---|---|

| Carbon (C) | 0.30 max | 0.03 max |

| Manganese (Mn) | 0.29-1.06 | 2.00 max |

| Phosphorus (P) | 0.050 max | 0.045 max |

| Sulfur (S) | 0.058 max | 0.03 max |

| Silicon (Si) | 0.10 min | 0.75 max |

| Chromium (Cr) | 0.40 max | 16.0-18.0 |

| Nickel (Ni) | 0.40 max | 10.0-14.0 |

| Molybdenum (Mo) | 0.15 max | 2.0-3.0 |

| Property | ASTM A234 WPB | ASTM A403 WP316L |

|---|---|---|

| Tensile Strength, min (MPa) | 415-585 | 515 |

| Yield Strength, min (MPa) | 240 | 205 |

| Elongation, min (%) | 22 | 30 |

| Hardness, max (HBW) | 197 | 217 |

Allows for efficient splitting or combining of fluid flows in complex piping layouts.

Designed to maintain the strength and integrity of the piping system.

Available to suit various pipe diameters, pressure ratings, and fluid compatibility.

Smooth internal contours minimize turbulence and pressure loss.

Different connection types offer flexibility in installation.

Manufactured from high-quality materials for long service life.

Description: All three openings are equal in diameter.

Description: One opening is smaller than the others.

Description: Internal bars to prevent pig entry.

Description: Branch connection at an angle (e.g., 45°).

Description: Curved branch for clean-out plug.

Description: Four equal-sized female openings.

| Material Type | Standards & Grades | Characteristics | Applications |

|---|---|---|---|

| Carbon Steel | ASTM A234 WPB, A420 WPL6, A105 | High strength, cost-effective, good weldability | General industrial piping, oil & gas, power generation |

| Stainless Steel | ASTM A403 WP304/304L, WP316/316L, WP321, WP347 | Excellent corrosion resistance, hygienic properties | Chemical processing, food & beverage, pharmaceutical |

| Alloy Steel | ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 | Enhanced strength, high-temperature resistance | High-temperature and high-pressure services |

Robust & Economical

Corrosion Resistant

High Performance

Install pipe tee

The basic application of the Split Tee is a connector that can be used in the middle of two pipes to allow them to join together.

Understanding the various pipe tee types allows engineers and contractors to make more informed decisions based on flow requirements, space limits, and material compatibility. Newzel Industries offers a diverse range of pipe tees in several grades, including SS 304, 316, and 321, all fabricated with accuracy to meet your industrial requirements. Contact us today for an estimate or technical assistance in determining the optimal pipe tee type for your project.

Y tees ensure corrosion-resistant, smooth fluid fl...

Large diameter elbows provide durable, corrosion-r...

Stainless steel tees are butt-weld pipe fittings d...

A lateral pipe tee means a pipe fitting which is s...

Reducing tee, like all pipe tees, is in the shape ...

The equal tee (equivalent tee or straight tee) is ...