What is Cast Basalt

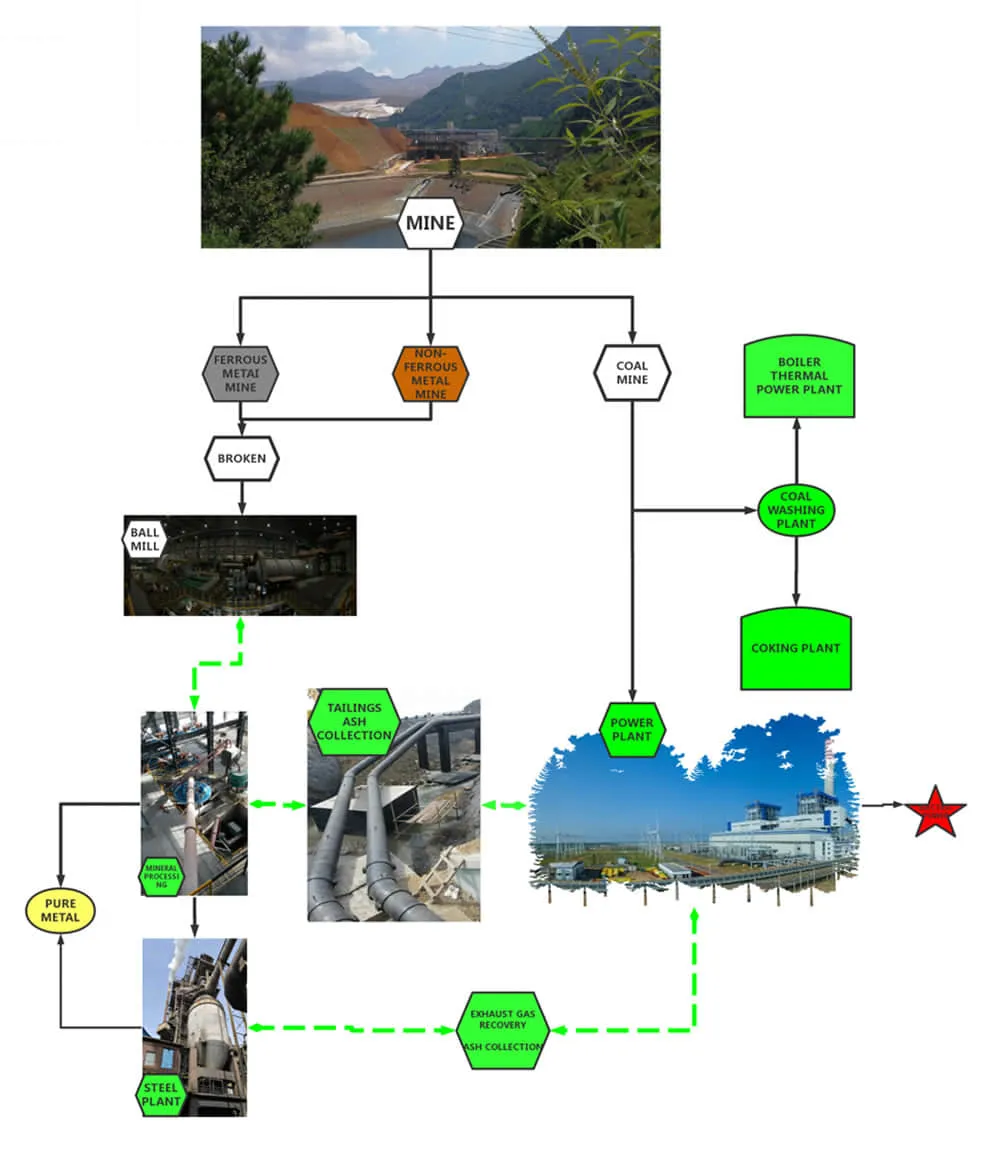

Cast basalt is a volcanic mineral material known for its exceptional abrasion resistance, complete impermeability to moisture, high compressive strength, and resistance to most acids and alkalis. It is entirely corrosion-proof, making it ideal for harsh industrial environments.

It is produced by melting selected natural basalt, crushed into 20–50 mm fragments, in shaft furnaces at approximately 1,300°C. The molten basalt is then cast and crystallizes into a uniform phaneritic structure, resulting in excellent hardness and wear resistance.

Cast basalt has a minimum hardness of 8 on the Mohs scale (diamonds are rated 10), making it extremely effective for abrasion and erosion protection.

Like other ceramics, it is sensitive to impact. Under normal service conditions, cast basalt withstands temperatures from -40°C to +350°C, but it should not be subjected to thermal shock.

Sizes: Cast basalt products come in the form of tiles, formed pieces, and segments. Straight pipes are spun-cast with nominal bores from 32 to 600 mm, wall thickness 20–30 mm, and standard lengths of 500 mm. Smaller bores, pipe segments with radii of 40–3000 mm, and special formed pieces are usually sand-cast. Steel molds can be used for higher volumes, producing 30–40 mm thick linings.