Flexible Connector For Small-diameter Piping Systems

Threaded rubber expansion joints absorb vibration, reduce noise, and manage thermal expansion in small-diameter piping, offering corrosion resistance and easy installation.

Flexible Connector For Small-diameter Piping Systems

Threaded rubber expansion joints absorb vibration, reduce noise, and manage thermal expansion in small-diameter piping, offering corrosion resistance and easy installation.

Threaded Rubber Expansion Joint, also known as a threaded union rubber joint, is a flexible connector designed for small-diameter industrial piping systems, typically ranging from 1/2” to 3” (DN15 to DN80). These joints are constructed from high-quality elastomers like EPDM, NBR, or Neoprene, reinforced with nylon cord or polyamide, and feature galvanized steel, stainless steel (SS304/SS316), or malleable iron threaded ends. They provide excellent corrosion resistance and are ideal for applications in HVAC, water supply, sewage systems, and sanitary pipeline solutions, ensuring pipeline vibration control and boiler pipeline protection.

The threaded rubber expansion joint is engineered to absorb axial, lateral, and angular movements, mitigating pipeline stress caused by thermal expansion, mechanical vibrations, or misalignment. With pressure ratings up to 16 bar and temperature ranges from -10°C to 105°C (depending on the elastomer), these joints are suited for media such as water, oil, air, and mild chemicals. Their seamless, high-density rubber construction enhances corrosion resistance, while threaded connections (BSP, NPT, or ISO standards) ensure easy installation without the need for flanges, making them cost-effective for pipeline vibration control.

Manufactured through vulcanization and molding, threaded rubber expansion joints undergo stringent testing, including pressure, vacuum, and fatigue tests, to comply with standards like DIN, ANSI, and JIS. Their elasticity reduces noise by up to 15-20 decibels and minimizes pipeline wear, extending system durability. The joints are particularly effective in systems with frequent thermal cycling or vibration, such as pumps, air conditioners, and fan coil units, providing reliable boiler pipeline protection.

Compared to flanged rubber expansion joints, threaded rubber expansion joints are more compact and lightweight, ideal for confined spaces or smaller pipelines. Their non-metallic body prevents electrolysis, enhancing durability in corrosive environments. Materials like NBR offer oil resistance, while EPDM excels in weathering and chemical resistance, making these joints versatile for sanitary pipeline solutions. However, they are less suited for high-pressure or large-diameter applications.

Threaded rubber expansion joints address critical challenges like vibration, noise, and thermal stress in small-scale piping systems. Their corrosion-resistant, easy-to-install design makes them a preferred choice for engineers seeking efficient, durable solutions for industrial piping and HVAC applications, ensuring operational safety and longevity.

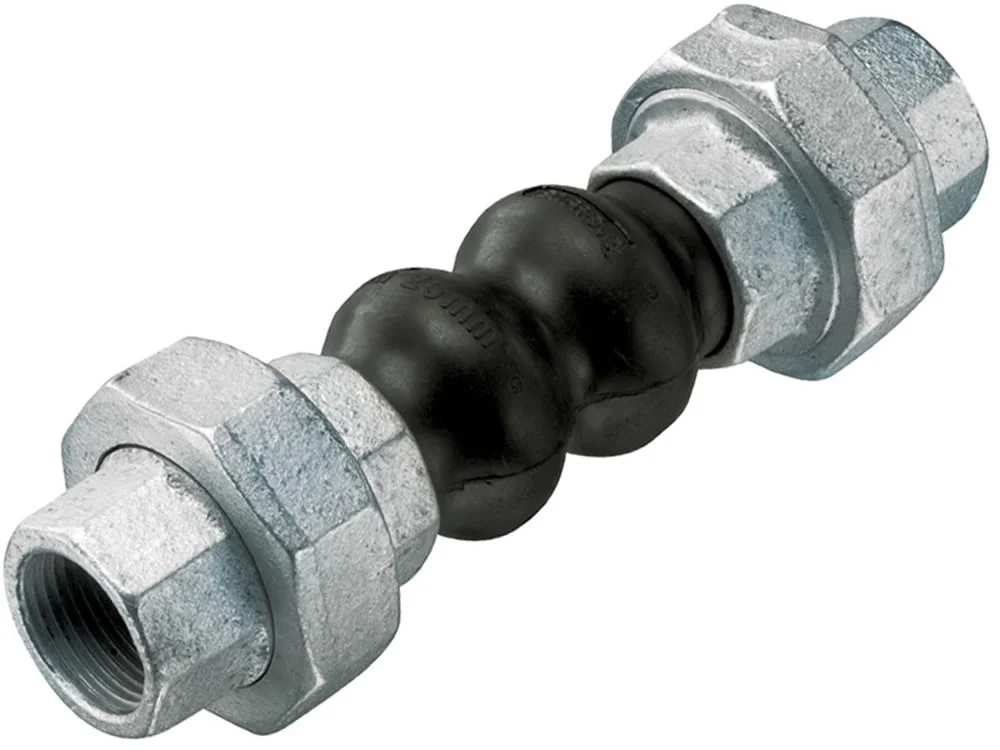

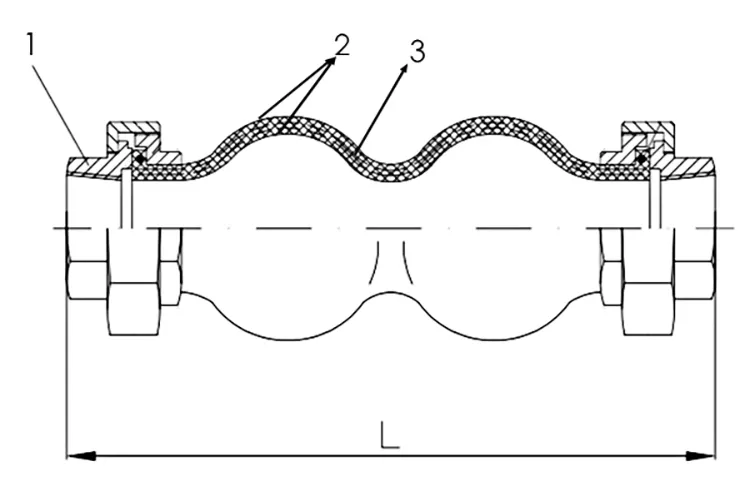

Double sphere union screwed rubber expansion joint is consist of union screwed and double sphere rubber expansion joint, the material of union screwed is usually malleable iron and stainless steel 304, the material of rubber is usually EPDM,Neoprene,NBR and natural rubber, the size is range from DN15 to DN80,namely since from 1/2inch to 3inch, the installation length of union screwed rubber expansion joint is usually 200mm, for DN65, it's 245mm, for DN80,it's 270mm. About working temperature, it's usually -15~+120 celsius degree, working pressure, it's usually PN16, this product is usually used in air conditioning fan coil etc.

| No. | Item | Material |

|---|---|---|

| 1 | Union | Malleable iron (stainless steel 304 is also ok) |

| 2 | Inner and outer layer of rubber | EPDM (Neoprene, NBR, NR is also ok) |

| 3 | Frame | Nylon cord fabric |

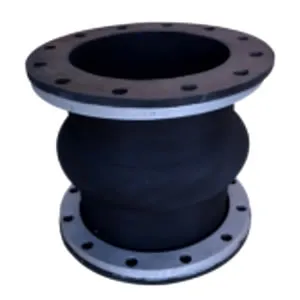

A Threaded Rubber Expansion Joint is a flexible connector designed to absorb vibration, reduce noise, and compensate for misalignment in piping systems. These joints are especially important in installations where mechanical stress, thermal expansion, or misalignment may cause damage or inefficiency.

Engineered with high-quality rubber and threaded connections, these expansion joints provide superior flexibility and durability. They can operate at burst pressures above 40 kg/cm², withstand normal internal pressures up to 10 kg/cm², and endure vacuum conditions of 700 mmHg, making them highly reliable for suction and discharge pump systems. In addition, they deliver excellent heat resistance for long-term performance.

Plumbing, HVAC, and hydraulic systems where vibration absorption and flexibility are essential.

Used in petrochemical, chemical, and food industries to control gas and liquid flow.

Installed in ships and watercraft to absorb engine and wave vibrations while ensuring smooth transfer.

Essential in suction and discharge pumps, reducing stress and extending equipment life.

Absorb greater movements compared to similar length metal expansion joints, managing lateral, torsional and angular movements effectively.

Dampen disturbances and provide resistance against shock stress from hydraulic surge and water hammer.

Dampen sound transmission with rubber to steel interface, reducing unwanted noise from system imbalances.

Lightweight and easy to handle, simplifying connections and reducing installation time and labor costs.

Significantly extend service life of piping systems and connected equipment, reducing maintenance frequency.

Effectively compensate for minor misalignments during installation or due to structural settling over time.

| Material | Temperature Range | Key Properties | Applications |

|---|---|---|---|

| EPDM Ethylene Propylene Diene Monomer |

-40°C to +120°C | Water, steam, ozone, weathering resistance | HVAC, water, wastewater systems |

| Nitrile (Buna-N) Acrylonitrile Butadiene |

-30°C to +100°C | Oil, fuel, chemical resistance | Petroleum-based applications |

| Hypalon Chlorosulfonated Polyethylene |

-40°C to +135°C | Ozone, weathering, oxidizing chemicals | Chemical processing, marine |

| Viton (FKM) Fluorocarbon |

-20°C to +200°C | High temperature, aggressive chemicals | Chemical, oil & gas, aerospace |

| Natural Rubber Polyisoprene |

-50°C to +80°C | Elasticity, abrasion resistance | General purpose, low chemical exposure |

Flexible rubber joints absorb vibration, reduce no...

Food grade rubber expansion joints ensure hygienic...

Limited flexible rubber joints absorb vibration, r...

Eccentric reducer rubber joints connect misaligned...

Flexible rubber elbow joints redirect flow in pipi...

Ein gummi-kompensator ist ein flexibles verbindung...