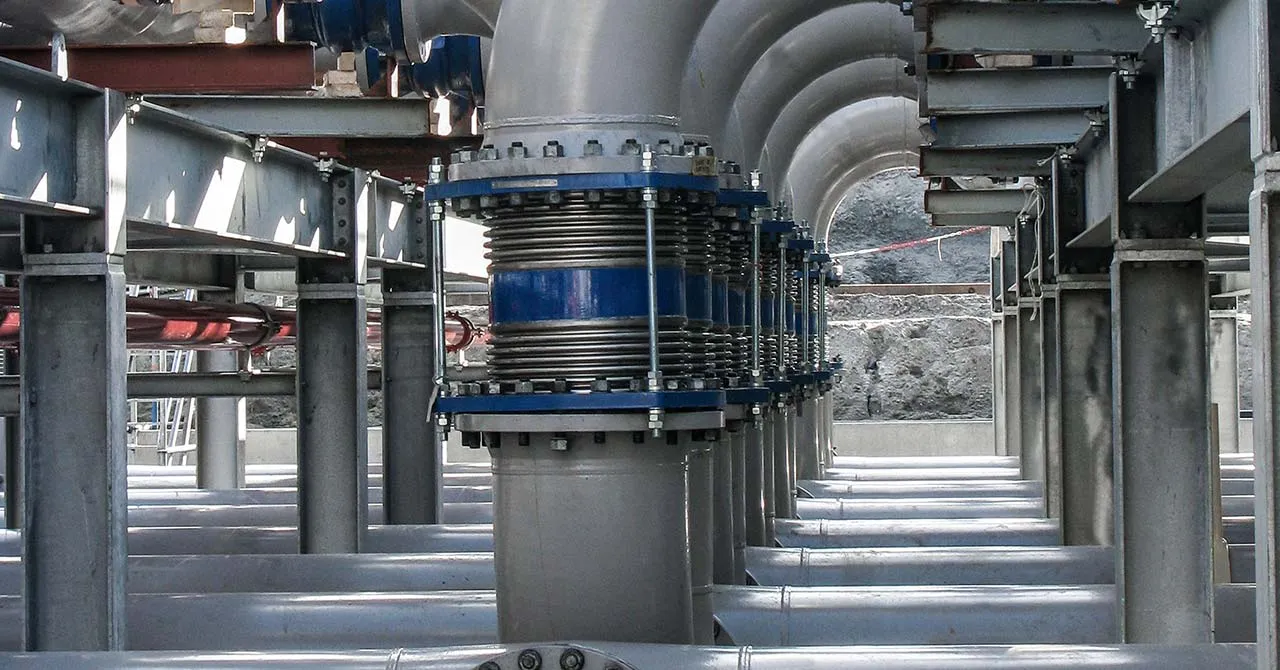

Stainless Steel Metal Hose is a highly durable and flexible connector designed for

industrial piping systems, offering exceptional corrosion resistance and

reliability under high-pressure and extreme temperature conditions. Constructed from T321 or T316L stainless steel

with single or double braiding (T304 or T316), these hoses are ideal for applications in chemical processing, oil

and gas, HVAC, and boiler pipeline protection. Their corrugated design ensures flexibility, while

the braiding enhances pressure capacity, making them suitable for flexible piping solutions in

demanding environments.

Available in sizes from 1/4” to 24” (DN6 to DN600), stainless steel metal hoses handle pressures up

to 3000 psi (depending on diameter and braiding) and temperatures from -320°F to 1500°F (-196°C to 815°C). They are

designed to absorb vibration, accommodate misalignment, and resist abrasion, making them perfect for

pipeline vibration control. The hoses are manufactured through annular or helical corrugation

processes, with welded fittings (carbon steel, stainless steel, or custom alloys) to ensure leak-proof connections.

They comply with standards like ISO 10380, ASME B31.3, and EJMA, ensuring quality and safety.

The corrosion resistance of stainless steel (T316L for enhanced chemical resistance, T321 for

high-temperature strength) makes these hoses ideal for handling corrosive fluids, gases, and abrasive materials in

industries like petrochemicals, refineries, and power generation. The braided construction provides burst

resistance, with double-braided options offering higher pressure ratings for critical applications. These hoses are

flexible enough for tight spaces and can be customized with liners for high-velocity flows to reduce turbulence and

wear.

Compared to rubber or PVC hoses, stainless steel metal hoses offer superior durability and

temperature tolerance, though they are heavier and costlier. Their ability to resist UV, ozone, and extreme climates

ensures longevity in harsh environments. They are suitable for cryogenic applications, steam lines, and

high-pressure gas transfer, with fittings like flanged, threaded, or welded ends for easy integration into

industrial piping systems. Rigorous testing, including hydrostatic, burst, and fatigue tests,

ensures compliance with industry standards and reliability in boiler pipeline protection.

Stainless steel metal hoses address challenges like pipeline wear, corrosion, and vibration in

high-throughput industrial systems. Their robust, corrosion-resistant design and flexibility make them a preferred

choice for engineers seeking reliable flexible piping solutions for extreme conditions, ensuring

safety, efficiency, and long-term performance in applications like chemical transfer, steam piping, and oil and gas

pipelines.

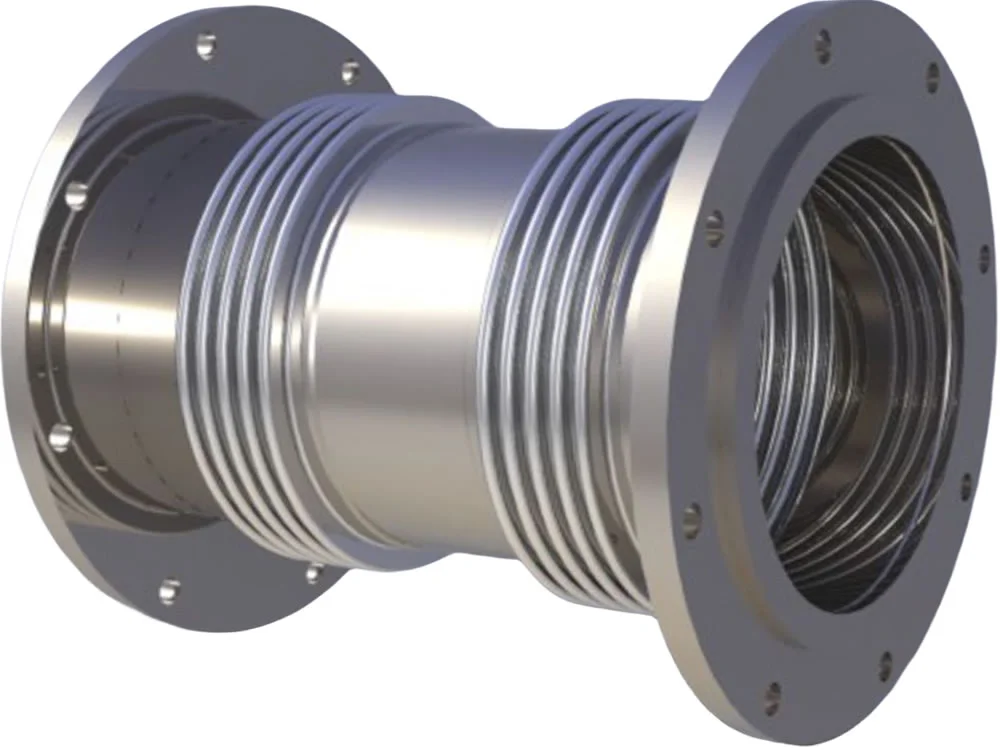

These hoses are constructed from thin-walled stainless steel tubes that are formed, welded, and corrugated to add

flexibility and strength.

Stainless steel metal hoses offer advantages such as high temperature resistance, corrosion resistance, and

durability. They are commonly used in industries like oil and gas, chemical processing, power generation, and food

processing, where there is a need for reliable and flexible hose assemblies.

These hoses can be single braided or double braided with stainless steel wire braidings for added reinforcement. The

braiding provides additional strength and protection against external damage.

Stainless steel metal hoses are available in various sizes, lengths, and pressure ratings to suit different

applications. They are often used for applications that require flexible connections, vibration absorption, or where

there is movement or misalignment between equipment.

When selecting a stainless steel metal hose, factors such as the type of fluid or gas being conveyed, operating

temperature and pressure, and compatibility with the surrounding environment should be considered.

It's important to consult with a reputable manufacturer or supplier to ensure that the stainless steel metal hose

chosen meets the specific requirements of the application.

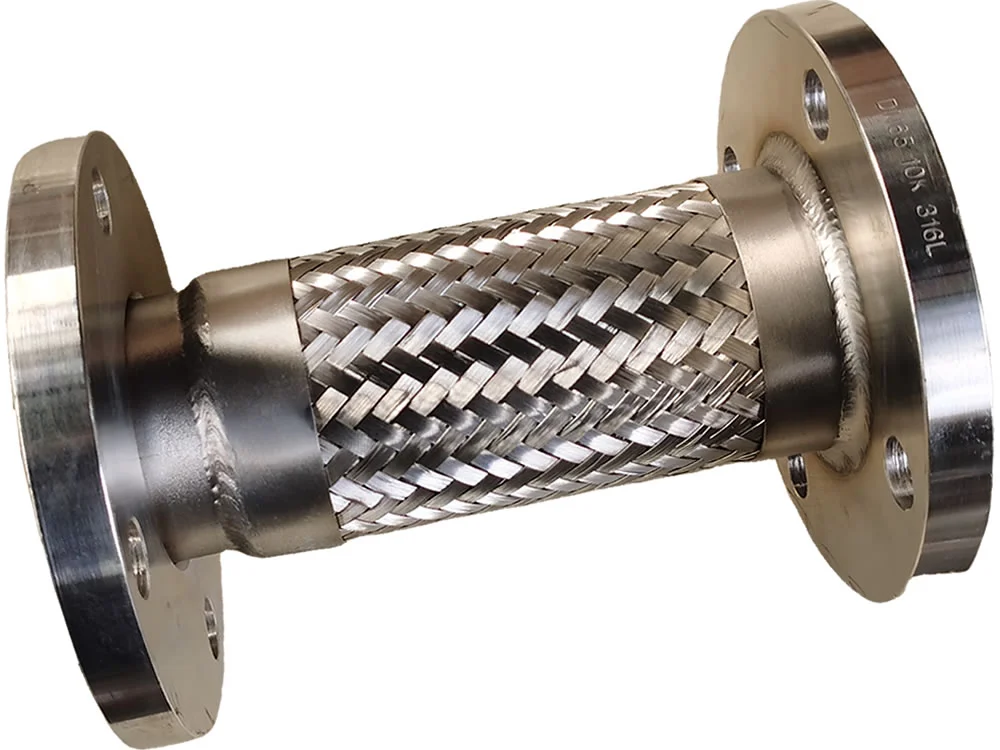

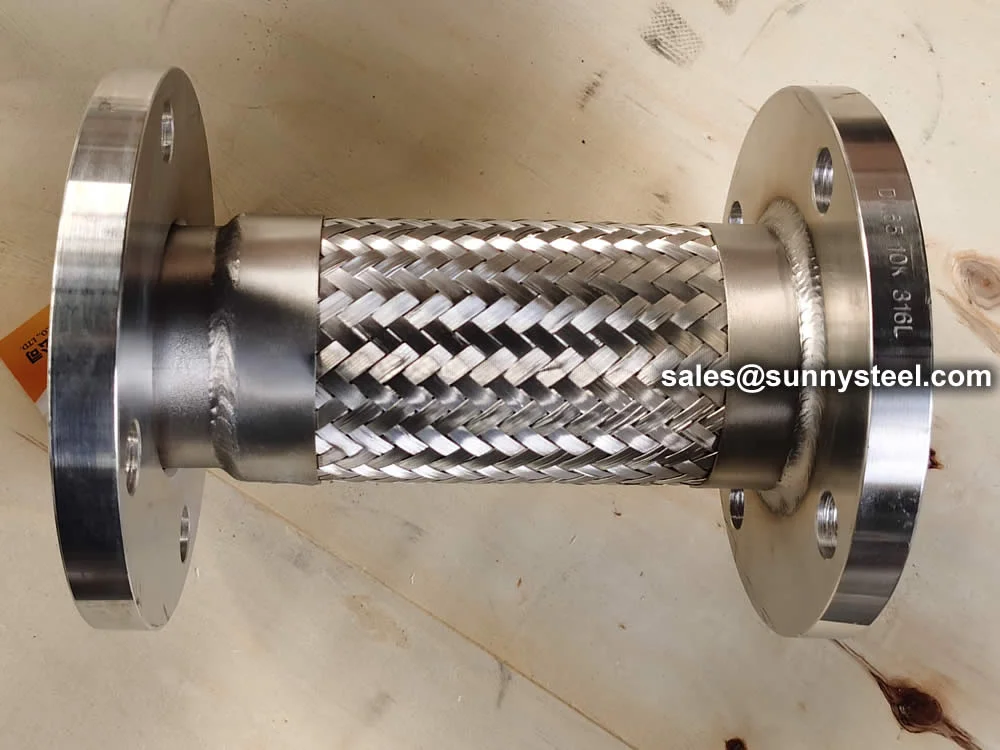

The inner tube of metal bellows hose is spiral or annular thin-wall stainless steel bellows, the outer braid mesh of

bellow pipe(corrugated pipe) is made of stainless steel wire and steel belt according to certain parameters,the

joints or flanges on both ends of the hose are matched to the joint or flange of the customer's pipe.

Flexible metal braided hose

Flexible metal hoses can withstand high temperatures, making them suitable for use

in high-temperature applications. They are commonly used in steam and hot water applications, as well as in

high-temperature air and gas applications.

Corrugated Pipe Specification Parameters (Units: mm for dimensions, MPa for pressure)

| Nominal diameter DN |

Inner diameter |

Outer diameter |

Minimum bending |

Working pressure |

| Bellows |

Braid mesh |

Static |

Dynamic |

Single braid mesh |

Double braid mesh |

| 8 |

8.8 |

13.2 |

14.4 |

50 |

110 |

15 |

20 |

| 10 |

11.7 |

16.5 |

17.7 |

65 |

145 |

185 |

20 |

| 15 |

13.5 |

19.5 |

21.1 |

80 |

180 |

18 |

20 |

| 20 |

20.0 |

27 |

28.6 |

120 |

270 |

10 |

15 |

| 25 |

27.0 |

34.5 |

36.1 |

160 |

360 |

6.3 |

10 |

| 32 |

32.0 |

40 |

41.6 |

175 |

400 |

4.0 |

6.3 |

| 40 |

39.6 |

52 |

53.6 |

225 |

510 |

4.0 |

6.3 |

| 50 |

49.7 |

62 |

63.6 |

280 |

640 |

3.0 |

5.0 |

| 65 |

61.2 |

80.2 |

81.8 |

410 |

915 |

3.0 |

5.0 |

| 80 |

79.0 |

96.3 |

97.9 |

486 |

1030 |

3.0 |

5.0 |

| 100 |

101.2 |

119.6 |

121.2 |

610 |

1340 |

2.5 |

4.0 |

| 125 |

124.1 |

145.3 |

146.9 |

700 |

1540 |

2.5 |

4.0 |

| 150 |

149.4 |

180.8 |

182.4 |

810 |

1780 |

2.5 |

4.0 |

Chemical Composition of Stainless Steel (Typical for T321/T316L)

| Element |

T321 (%) |

T316L (%) |

| Carbon (C) |

≤0.08 |

≤0.03 |

| Chromium (Cr) |

17.0-19.0 |

16.0-18.0 |

| Nickel (Ni) |

9.0-12.0 |

10.0-14.0 |

| Molybdenum (Mo) |

– |

2.0-3.0 |

| Titanium (Ti) |

5xC-0.70 |

– |

| Iron (Fe) |

Balance |

Balance |

Mechanical Properties of Stainless Steel Metal Hose

| Property |

Value |

| Tensile Strength (MPa) |

515-690 |

| Yield Strength (MPa) |

205-275 |

| Elongation (%) |

≥40 |

| Pressure Rating (psi) |

Up to 3000 (varies by size) |

| Temperature Range (°C) |

-196 to 815 |

FAQs

Types of Stainless Steel Metal Hoses

Stainless steel hoses are available in different types to suit various industrial

applications. Each type offers unique advantages in terms of flexibility, pressure resistance, and durability.

Corrugated Stainless Steel Hoses

Designed with continuous corrugations for excellent flexibility and bending

capability. Ideal for absorbing vibrations, compensating for thermal expansion, and accommodating

movement in piping systems.

Braided Stainless Steel Hoses

Consist of a corrugated inner hose with an external stainless steel braid that

enhances pressure resistance and strength. Commonly used in high-pressure and demanding industrial

applications.

Unbraided Stainless Steel Hoses

Basic corrugated hoses without an outer braid. Lightweight, flexible, and easy to

handle—ideal for low-pressure or less demanding applications where maximum flexibility is required.