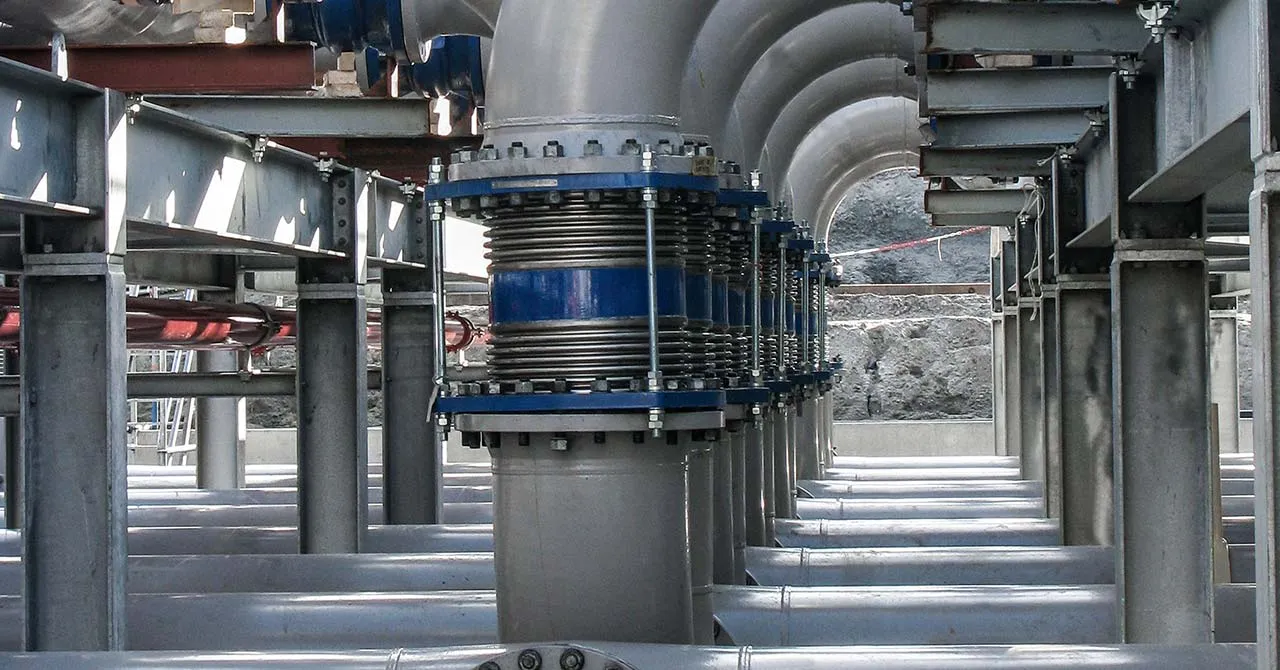

Metallic Pipe Expansion Joints are critical components in industrial piping systems, designed to absorb thermal expansion, mechanical vibration, and misalignment while maintaining system integrity. Made from high-quality materials like stainless steel, Inconel, or Hastelloy, these joints offer exceptional corrosion resistance and durability, making them ideal for demanding applications in oil and gas, petrochemicals, power generation, and boiler pipeline protection. Their robust design ensures reliable performance under high-pressure and high-temperature conditions.

Available in sizes from 2” to 144” (DN50 to DN3600), metallic pipe expansion joints handle pressures up to 500 psi and temperatures from -300°F to 2200°F (-184°C to 1204°C), depending on material and configuration. They are manufactured with single or multiple bellows, using materials like T304, T316L, or high-nickel alloys to ensure corrosion resistance. Configurations include single, universal, hinged, gimbal, and pressure-balanced joints, each tailored to specific movement requirements (axial, lateral, or angular). These joints comply with standards like EJMA, ASME B31.3, and ASTM F-1120, ensuring quality and safety.

The primary function of metallic pipe expansion joints is to mitigate stresses from thermal expansion and contraction, reducing the risk of pipeline damage. Their vibration damping capabilities protect equipment like pumps and turbines, while their flexibility accommodates misalignment in complex piping systems. Stainless steel bellows provide excellent resistance to corrosive media, making them suitable for chemical processing and wastewater treatment. Optional features like tie rods, liners, and external covers enhance performance in high-velocity flows or extreme environments.

Compared to rubber or fabric joints, metallic pipe expansion joints excel in high-pressure and high-temperature applications, though they may require more robust anchoring due to pressure thrust. They are ideal for steam lines, exhaust systems, and industrial piping solutions where durability is critical. Rigorous testing, including hydrostatic, radiographic, and fatigue tests, ensures compliance with industry standards. Custom designs, such as PTFE-lined or dual-bellows configurations, cater to specific project needs, enhancing versatility.

Metallic pipe expansion joints address challenges like pipeline wear, corrosion, and thermal stress in high-throughput systems. Their corrosion-resistant, flexible design makes them a preferred choice for engineers seeking reliable thermal expansion joints for extreme conditions, ensuring safety, efficiency, and longevity in applications like refineries, power plants, and HVAC systems.

Types of metal expansion joints

They consist of one or more metal bellows, connectors at both ends, and tie rods, depending on the application. Metal expansion joints are differentiated based on the three basic types of movement: axial, angular, and lateral expansion joints .

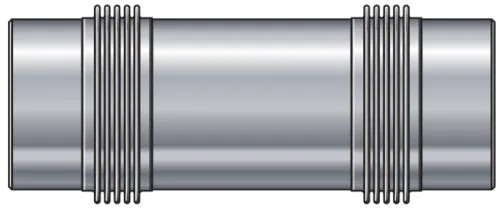

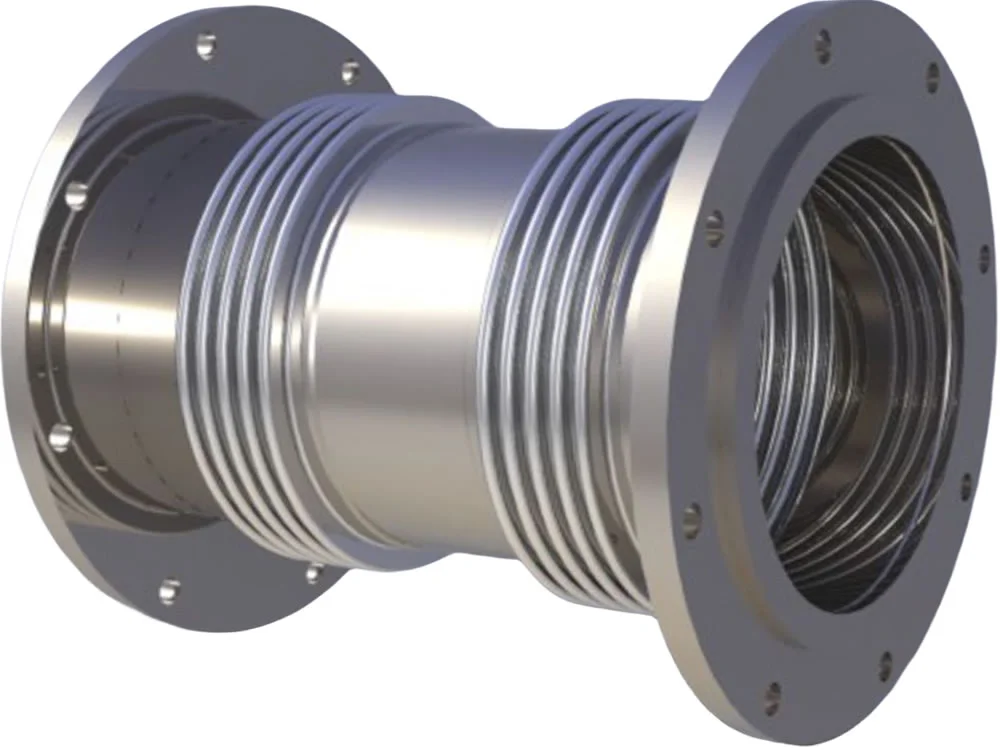

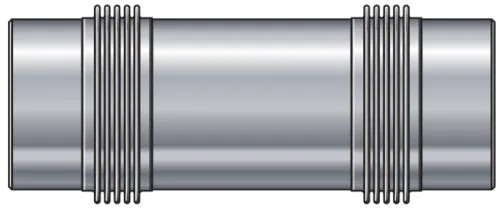

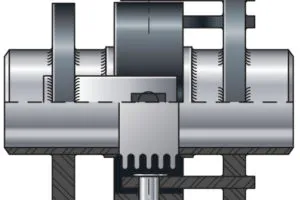

Single unrestrained

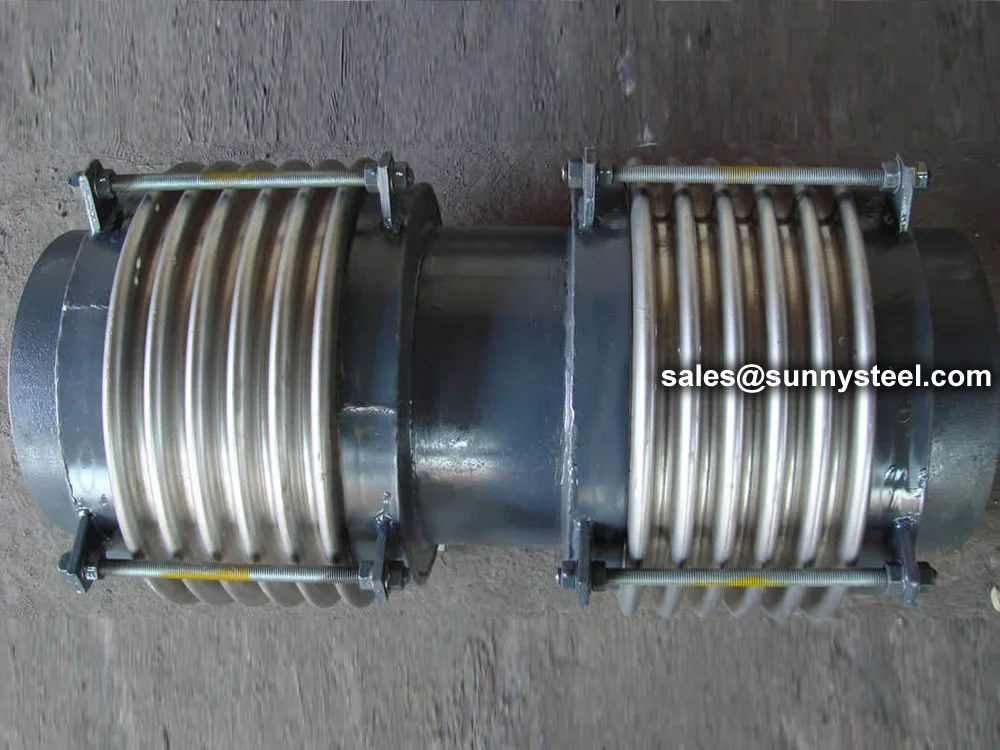

This expansion joint is the simplest one available and comes with one bellows section and end connections. This type of expansion joint requires the most control of the adjacent piping in regards to anchors and guiding.

Single tied expansion joint

This expansion joint is exactly like the single unrestrained expansion joint but it is provided with tie rods. When adding tie rods to the expansion joint it stops the bellows from overextending. The tie rods act as limit rods and has stops set to allow axial movement to a specifically designed movement.

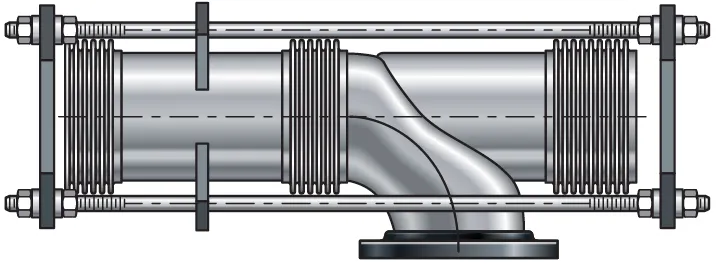

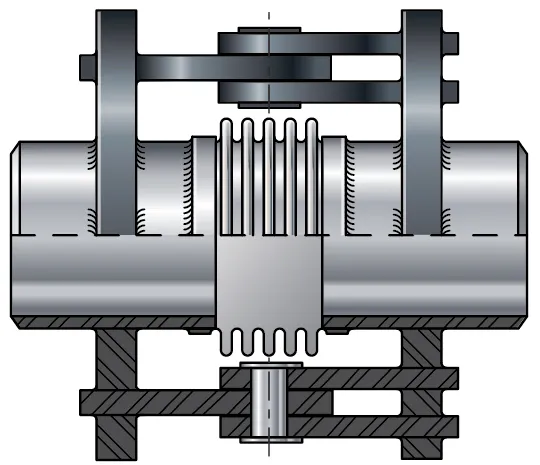

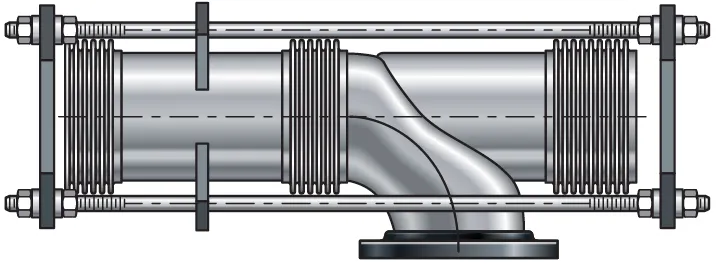

Pressure balanced elbow expansion joint

This expansion joint is designed to not only restrain the pressure thrust but in addition, balances the pressure thrust so as not to have anchoring of the adjacent piping or equipment. This pressure balanced elbow expansion joint can be designed as single or universal depending on how much lateral movement is required.

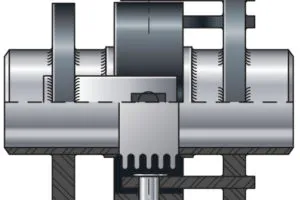

Hinged expansion joint

This expansion joint has a single bellows section and is designed to allow angular rotation in one plane only. The hinge hardware is rigid in the axial direction so as not to allow the expansion joint to allow axial movement in piping systems. The hinged expansion joint is usually used in pairs of threes or in combination with a gimbal expansion joint.

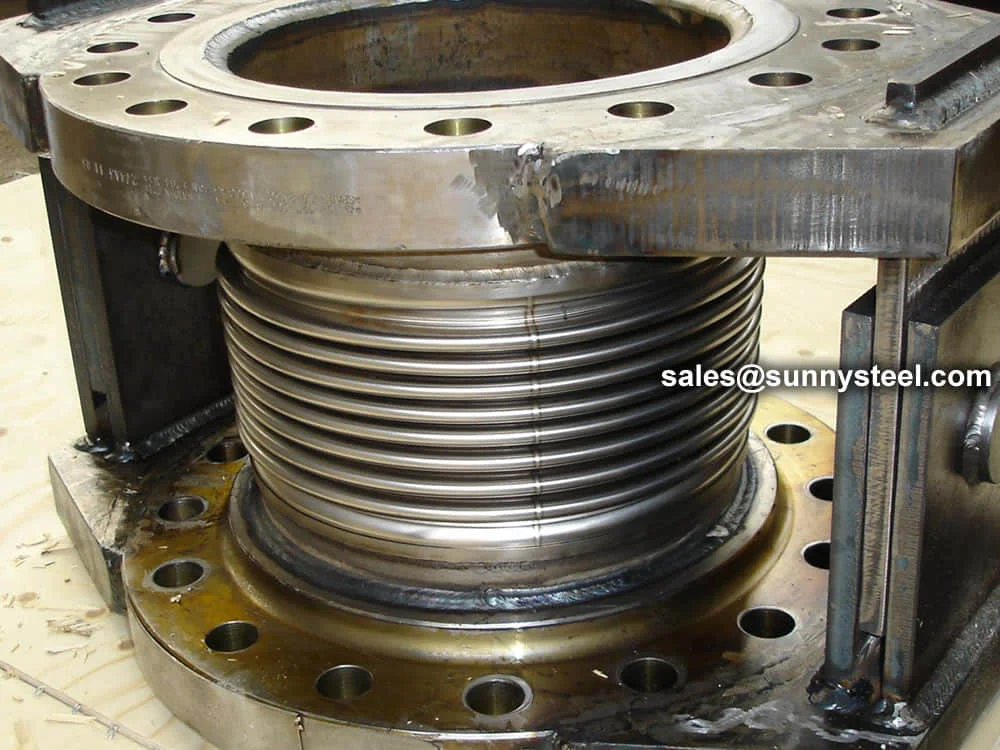

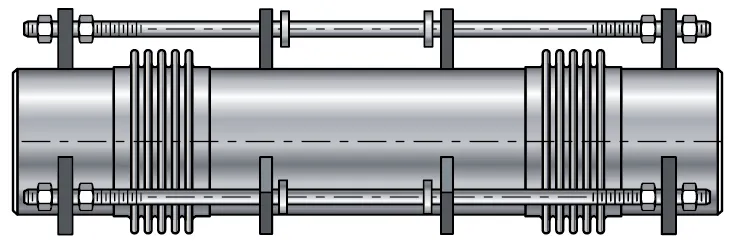

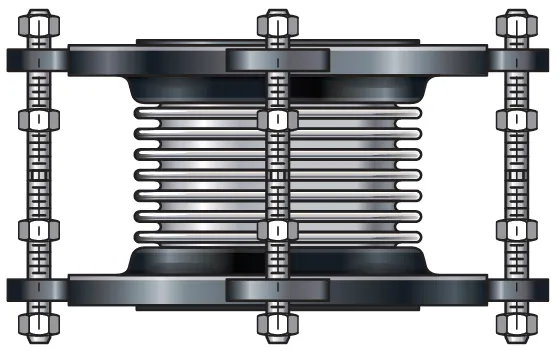

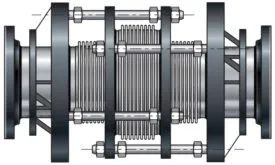

Universal expansion joint

This expansion joint has two bellows sections connected by a center pipe section. This design allows for large amounts of lateral deflection. The universal can also allow for axial and angular movements in addition to the lateral movement. This expansion joint does not come with the hardware to resist pressure thrust. Like the single unrestrained expansion joint the universal expansion joint must be properly anchored and supported.

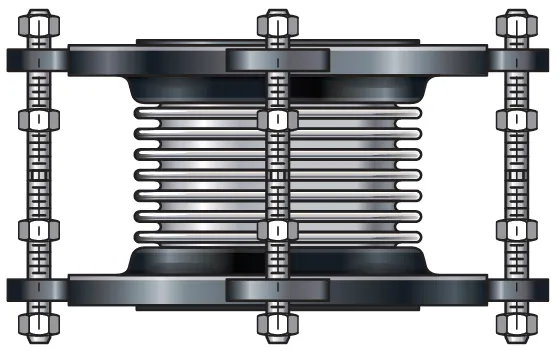

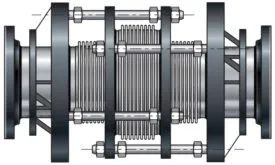

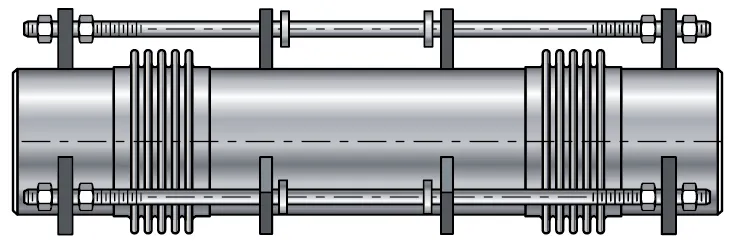

Tied universal expansion joint

This expansion joint is exactly like the universal expansion joint but the tie rods have been designed into the unit. By adding the tie rods you restrain pressure thrust. The pressure balance expansion joint will not accept external axial movement without overcoming this pressure thrust force.

Universal expansion joint

This expansion joint has a single bellows section. The gimbal expansion joint is designed to allow angular rotation in any plane by using two pairs of hinges connected to a common central floating ring. The gimbal expansion joint is usually used in pairs of threes or in combination with the hinged expansion joint.

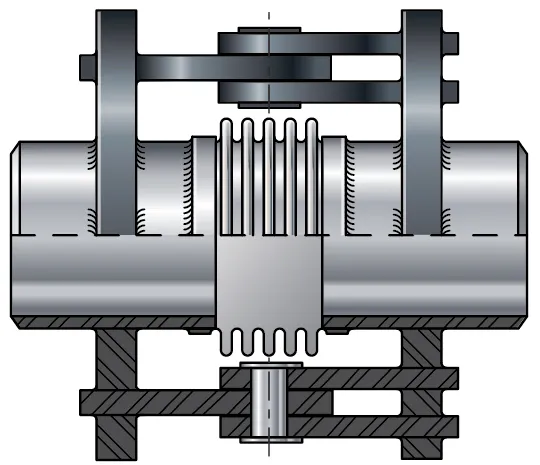

In-line pressure balanced expansion joint

This expansion joint is unusual in its’ design in that it absorbs lateral, axial, and angular movement. This in-line pressure balanced expansion joint is designed for cases where the main anchoring is not feasible or pressure loads are to high for equipment like pumps and turbines.