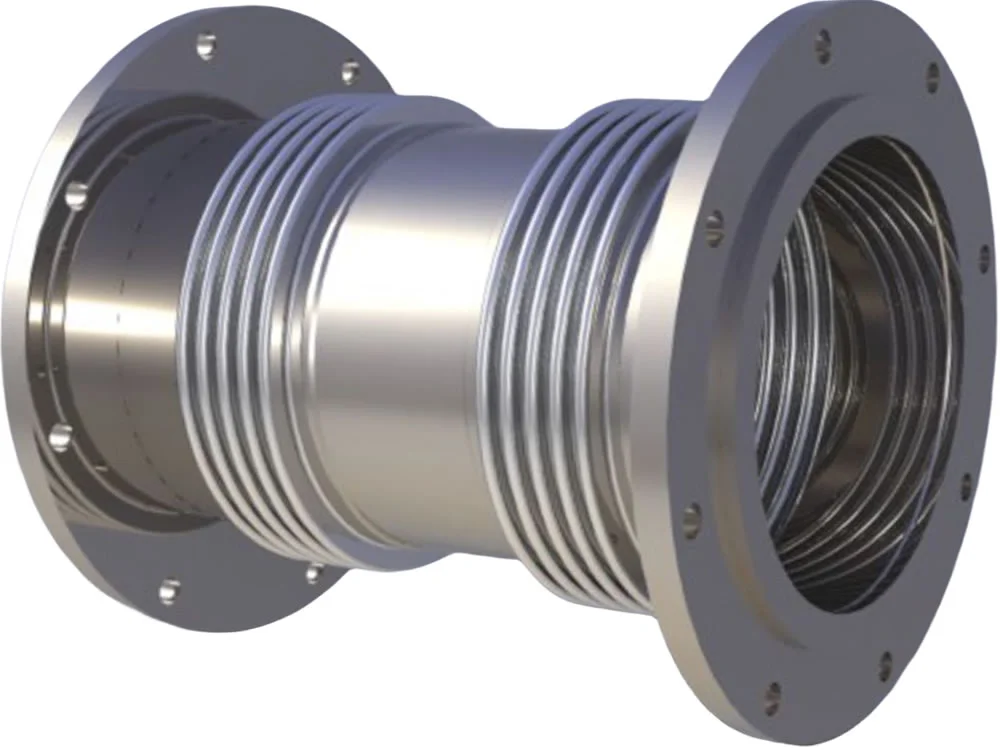

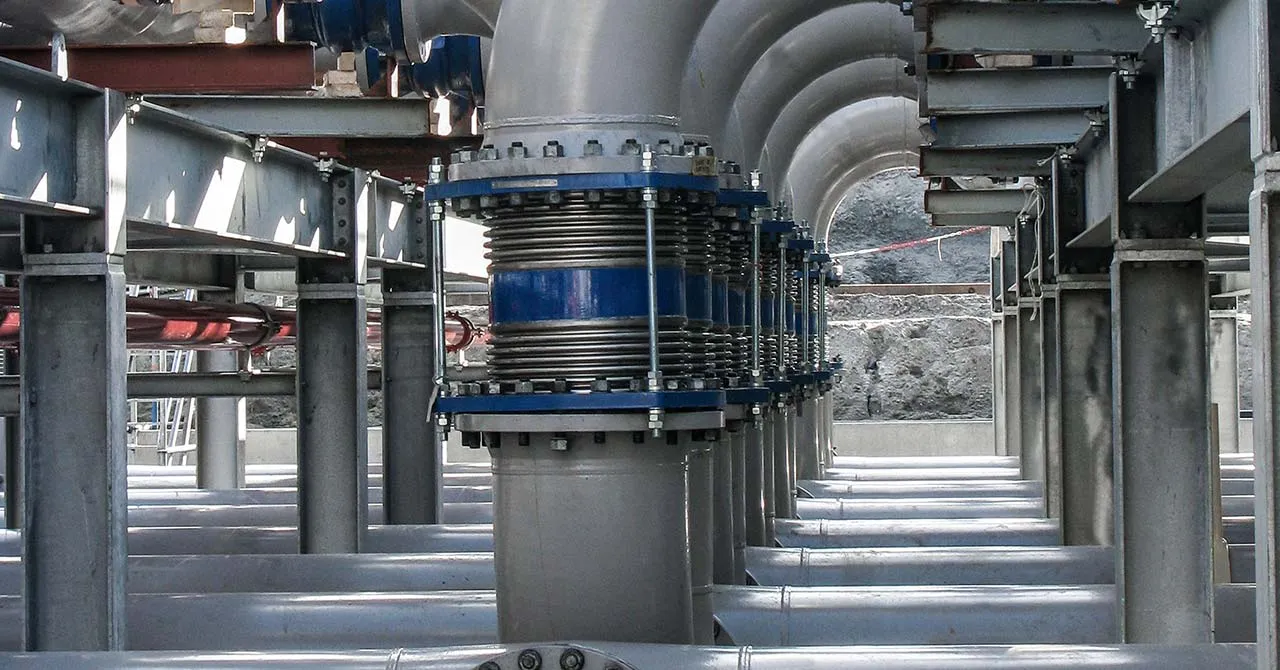

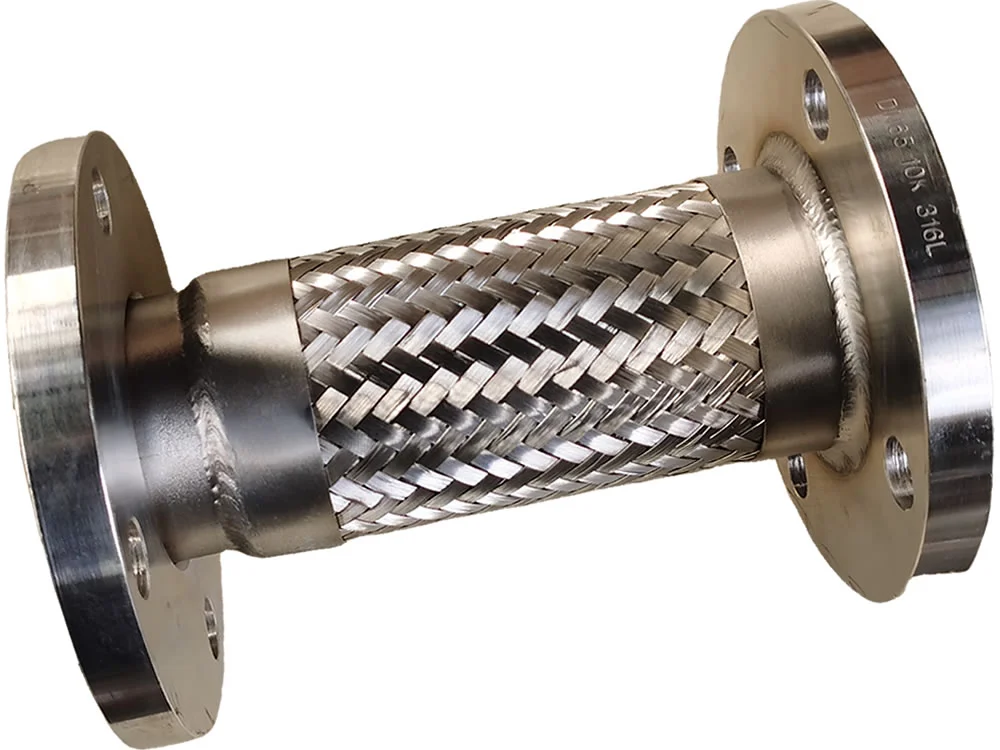

Metal Expansion Joints are essential components in industrial piping systems, designed to absorb thermal expansion, mechanical vibrations, and misalignment while ensuring system reliability. Constructed from materials like stainless steel (T304, T316L), Inconel, or Hastelloy, these joints provide superior corrosion resistance and durability, making them ideal for applications in oil and gas, chemical processing, power generation, and boiler pipeline protection. Their bellows design allows flexibility and strength under extreme conditions.

Available in sizes ranging from 2” to 144” (DN50 to DN3600), metal expansion joints can handle pressures up to 500 psi and temperatures from -300°F to 2200°F (-184°C to 1204°C), depending on the material and configuration. They are available in various types, including single, universal, hinged, gimbal, and pressure-balanced joints, to accommodate axial, lateral, or angular movements. Compliant with standards like EJMA, ASME B31.3, and ASTM F-1120, these joints ensure quality and safety in industrial piping solutions.

The corrosion resistance of materials like T316L (with molybdenum for enhanced chemical resistance) and Inconel (for high-temperature strength) makes these joints suitable for handling corrosive fluids, gases, and abrasive media in industries such as petrochemicals and refineries. Their vibration damping capabilities protect critical equipment like pumps and turbines, while their flexibility mitigates pipeline stress caused by thermal expansion or contraction. Optional features like internal liners, tie rods, and external covers enhance performance in high-velocity flows or harsh environments.

Compared to rubber expansion joints, metal expansion joints offer superior performance in high-pressure and high-temperature applications, though they require stronger anchoring to manage pressure thrust. They are ideal for steam lines, exhaust systems, and high-temperature fluid transfer, with fittings like flanged or welded ends for seamless integration. Rigorous testing, including hydrostatic, radiographic, and cycle life tests, ensures reliability and compliance with industry standards, making them a trusted choice for boiler pipeline protection.

Metal expansion joints address critical challenges like pipeline wear, corrosion, and thermal stress in high-throughput industrial systems. Their robust, corrosion-resistant design and flexibility make them a preferred solution for engineers seeking durable thermal expansion joints for extreme environments, ensuring safety, efficiency, and longevity in applications like power plants, HVAC systems, and chemical processing.

The force of a pipe's expansion due to thermal expansion and vibration is immense and can cause considerable damage and long periods of downtime. A well-designed expansion joint is very important for this reason.

Types of metal expansion joints

They consist of one or more metal bellows, connectors at both ends, and tie rods, depending on the application. Metal expansion joints are differentiated based on the three basic types of movement: axial, angular, and lateral expansion joints .

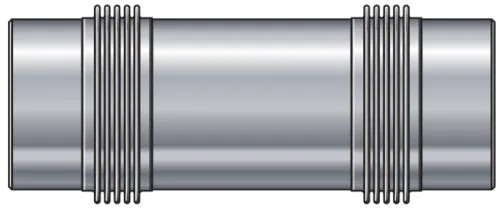

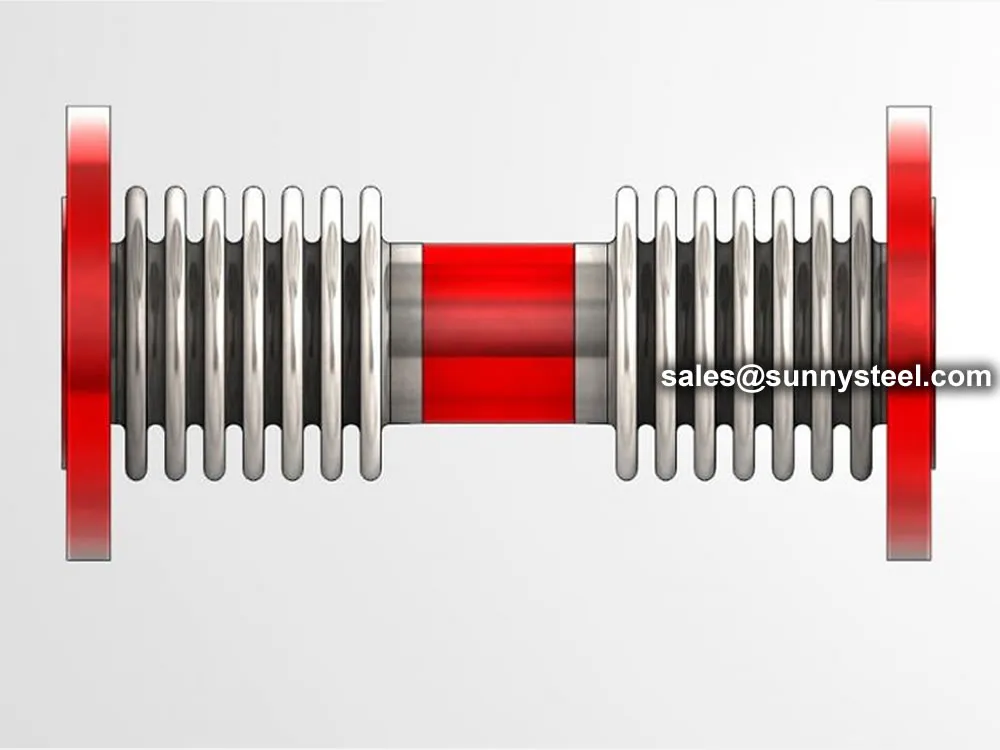

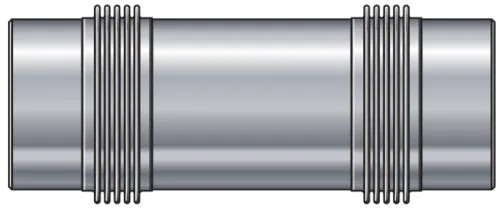

Single unrestrained

This expansion joint is the simplest one available and comes with one bellows section and end connections. This type of expansion joint requires the most control of the adjacent piping in regards to anchors and guiding.

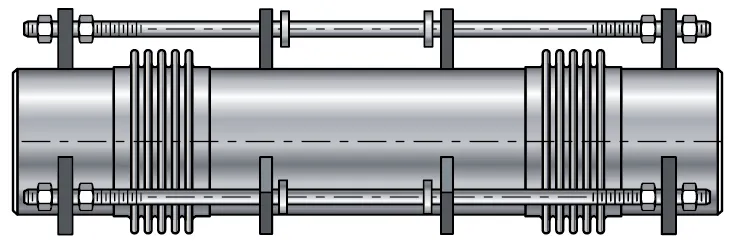

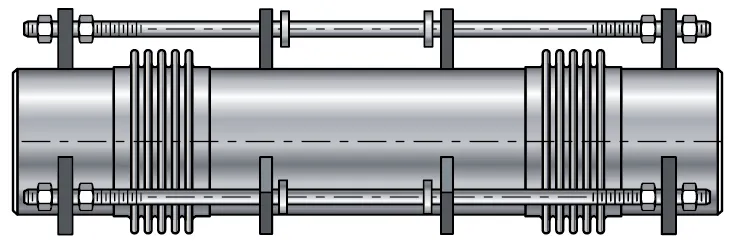

Single tied expansion joint

This expansion joint is exactly like the single unrestrained expansion joint but it is provided with tie rods. When adding tie rods to the expansion joint it stops the bellows from overextending. The tie rods act as limit rods and has stops set to allow axial movement to a specifically designed movement.

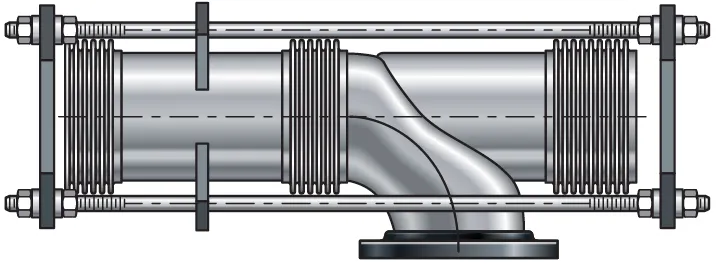

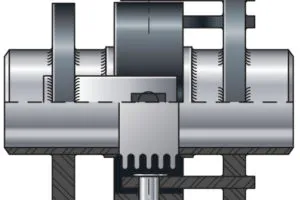

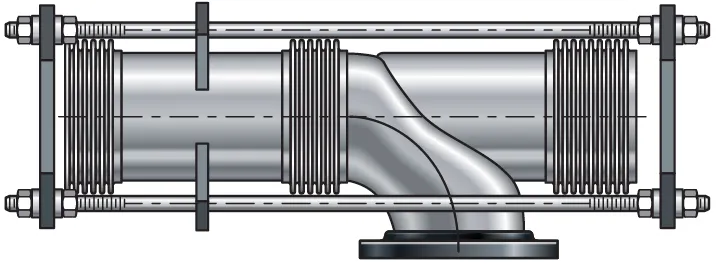

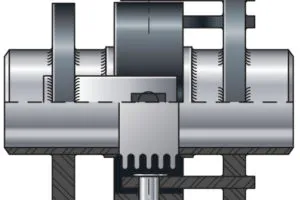

Pressure balanced elbow expansion joint

This expansion joint is designed to not only restrain the pressure thrust but in addition, balances the pressure thrust so as not to have anchoring of the adjacent piping or equipment. This pressure balanced elbow expansion joint can be designed as single or universal depending on how much lateral movement is required.

Hinged expansion joint

This expansion joint has a single bellows section and is designed to allow angular rotation in one plane only. The hinge hardware is rigid in the axial direction so as not to allow the expansion joint to allow axial movement in piping systems. The hinged expansion joint is usually used in pairs of threes or in combination with a gimbal expansion joint.

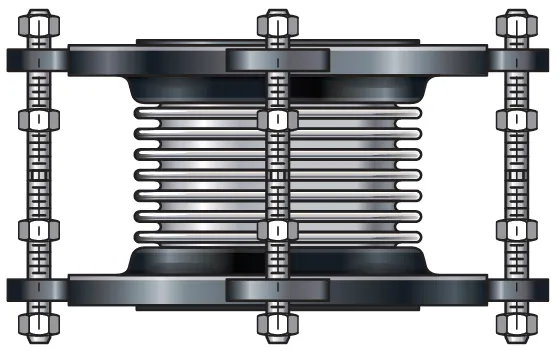

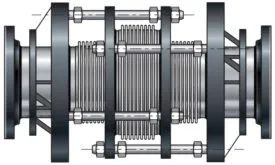

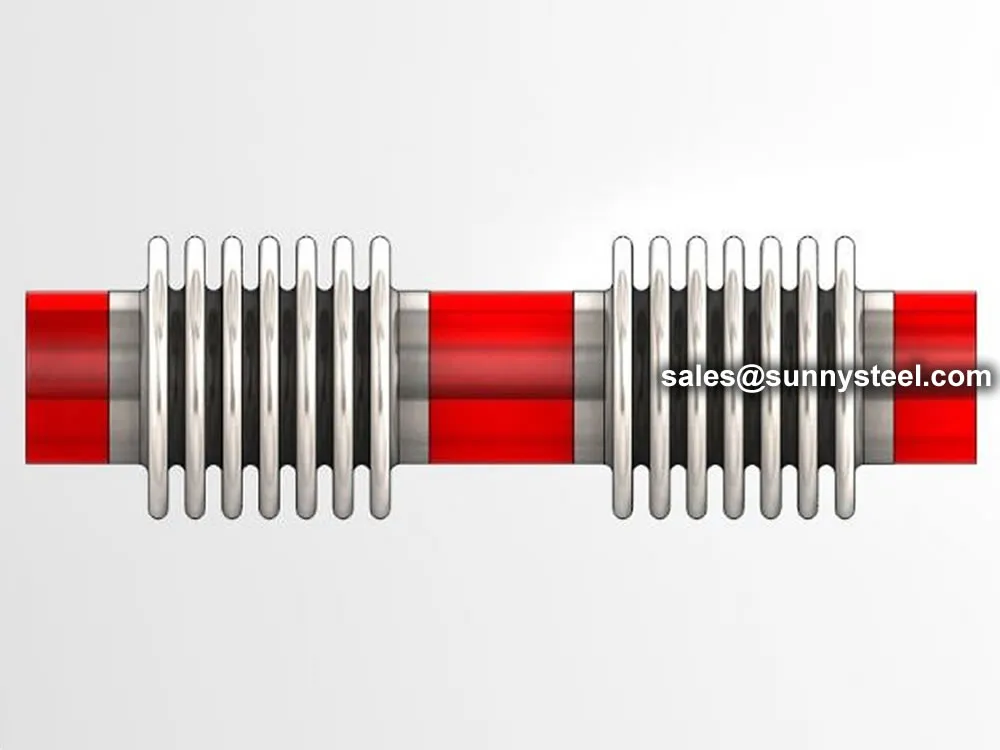

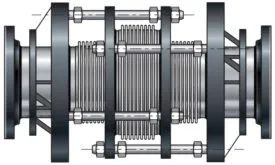

Universal expansion joint

This expansion joint has two bellows sections connected by a center pipe section. This design allows for large amounts of lateral deflection. The universal can also allow for axial and angular movements in addition to the lateral movement. This expansion joint does not come with the hardware to resist pressure thrust. Like the single unrestrained expansion joint the universal expansion joint must be properly anchored and supported.

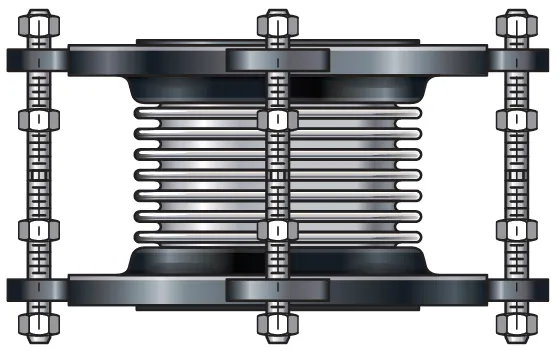

Tied universal expansion joint

This expansion joint is exactly like the universal expansion joint but the tie rods have been designed into the unit. By adding the tie rods you restrain pressure thrust. The pressure balance expansion joint will not accept external axial movement without overcoming this pressure thrust force.

Universal expansion joint

This expansion joint has a single bellows section. The gimbal expansion joint is designed to allow angular rotation in any plane by using two pairs of hinges connected to a common central floating ring. The gimbal expansion joint is usually used in pairs of threes or in combination with the hinged expansion joint.

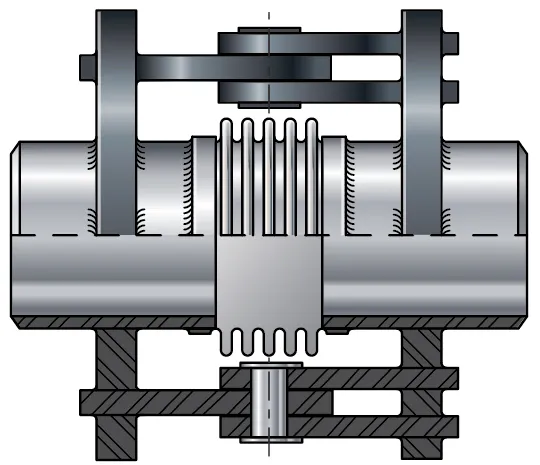

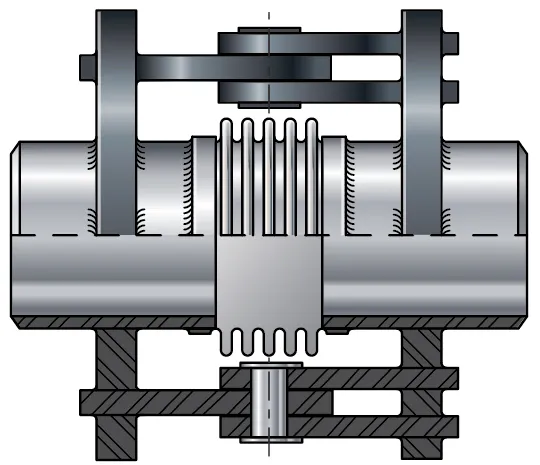

In-line pressure balanced expansion joint

This expansion joint is unusual in its’ design in that it absorbs lateral, axial, and angular movement. This in-line pressure balanced expansion joint is designed for cases where the main anchoring is not feasible or pressure loads are to high for equipment like pumps and turbines.