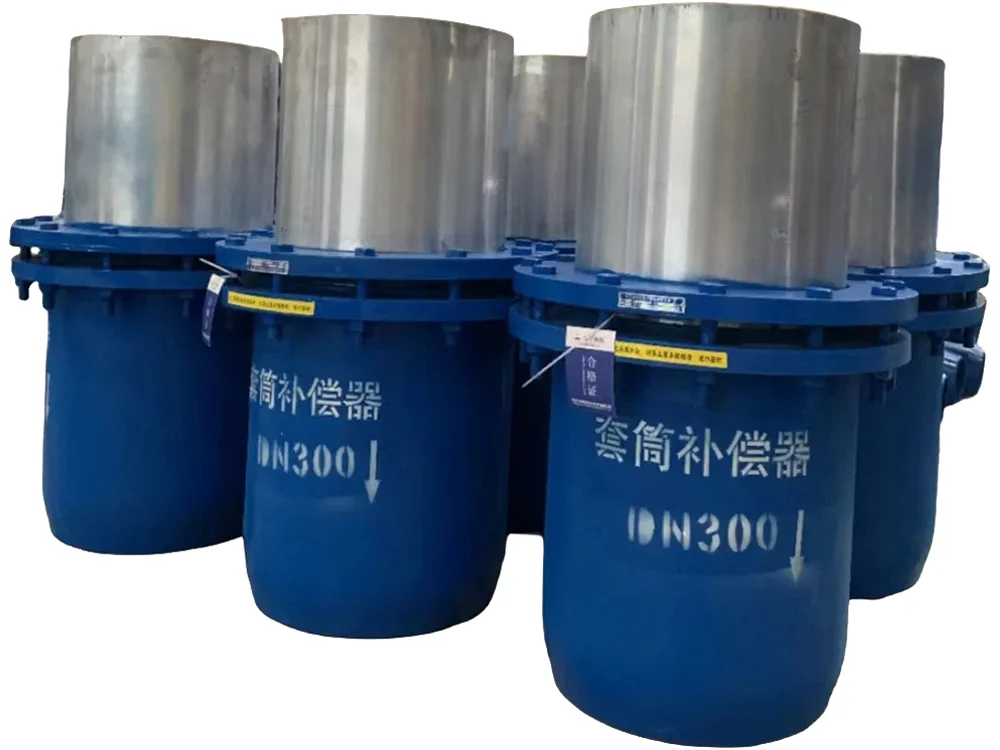

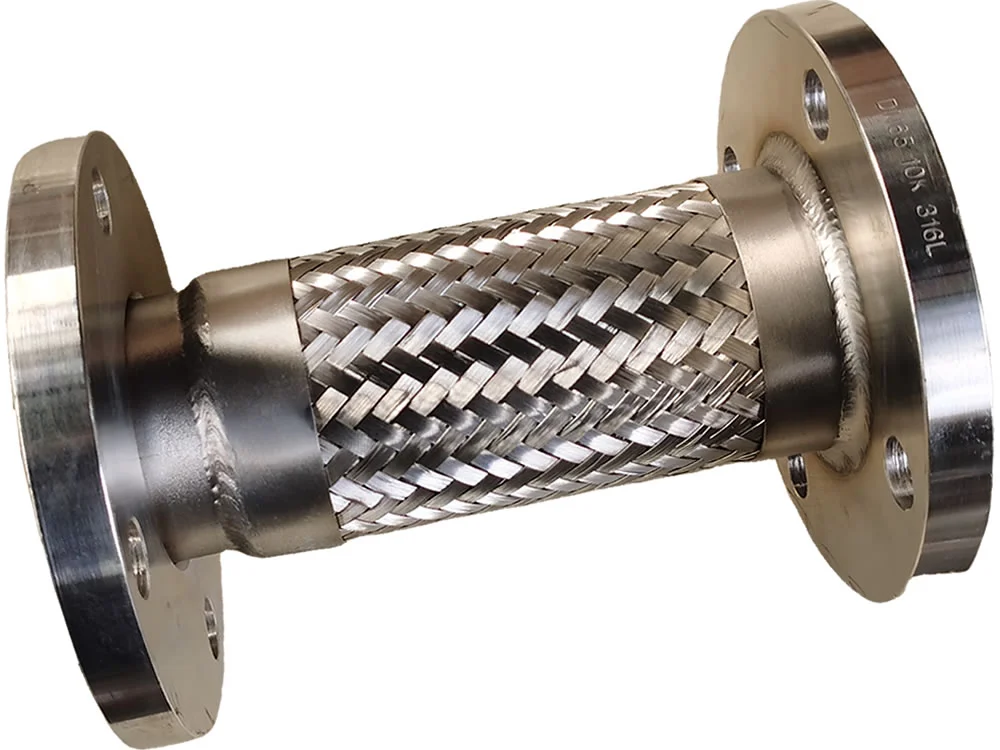

Sleeve Compensators, also known as sleeve-type expansion joints, are vital components

in industrial piping solutions, designed to absorb axial movement caused by thermal expansion and

contraction while ensuring system integrity. Constructed from materials like stainless steel, carbon steel, or

copper, these compensators offer excellent corrosion resistance and durability, making them ideal

for applications in power plants, chemical processing, water supply systems, and boiler pipeline

protection. Their non-thrust design minimizes stress on adjacent equipment, enhancing system

reliability.

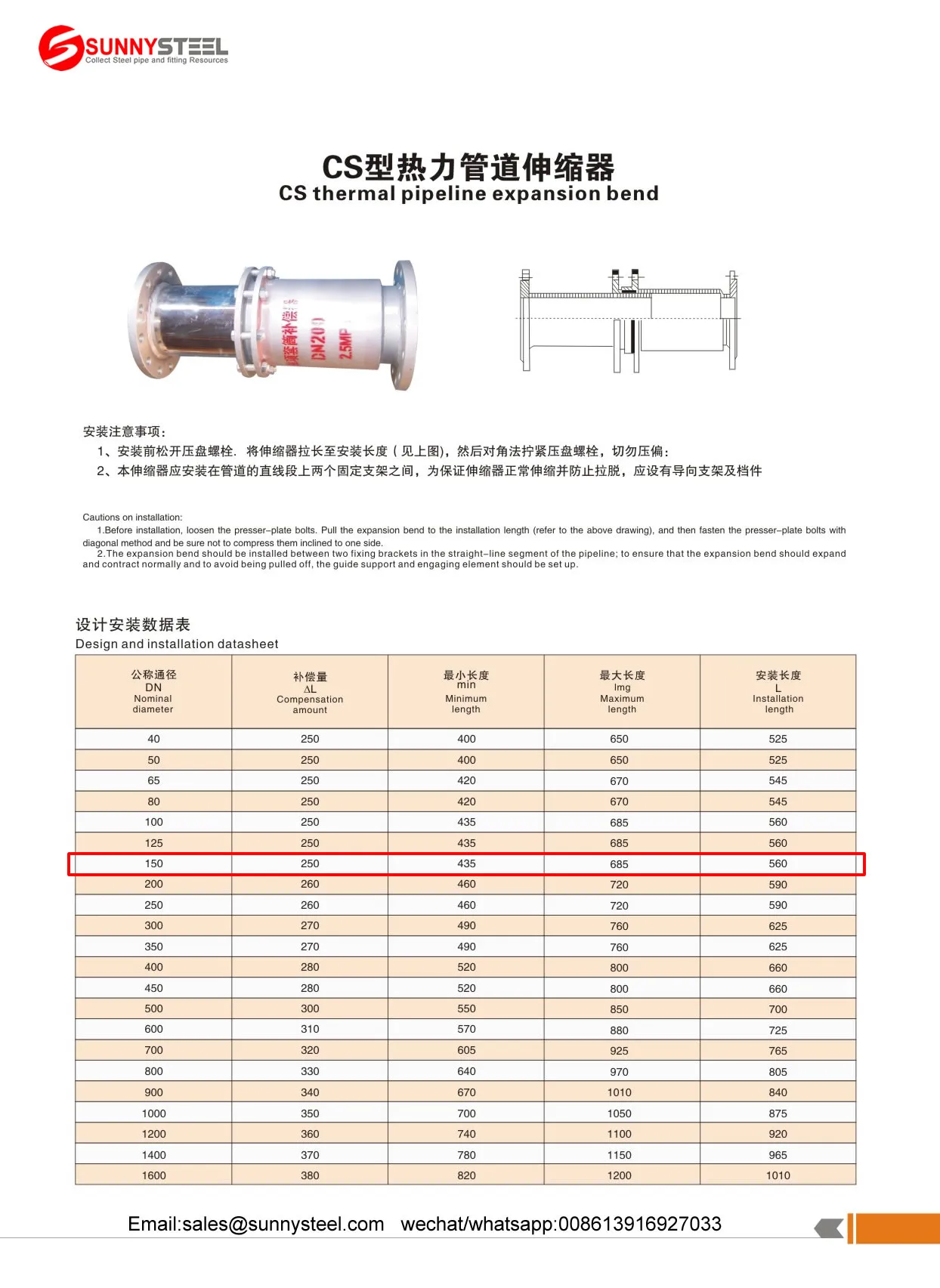

Available in sizes from 2” to 36” (DN50 to DN900), sleeve compensators are suitable for pressures

up to 2.5 MPa and temperatures ranging from -40°C to 600°C, depending on the material and sealing configuration.

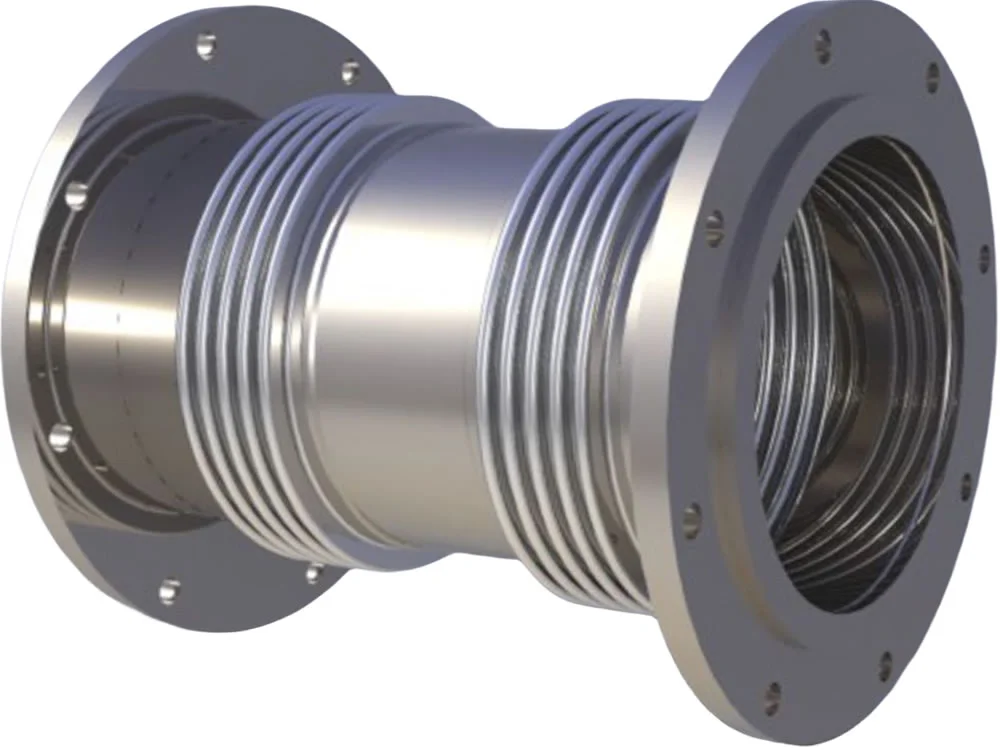

They feature a sliding sleeve mechanism with flexible graphite or EPDM seals, providing low friction (0.04-0.10) and

robust sealing to prevent leaks. These compensators are designed for axial movement compensation, with single-way

and two-way structures available to accommodate varying pipeline requirements. They comply with standards like API

1102 and ASME Section VIII for quality assurance.

The sleeve compensator excels in environments with high chloride ion content, as its sealing

materials resist corrosion in saltwater and harsh chemical conditions. The sliding surface offers corrosion

resistance up to 50 times higher than austenitic stainless steel in saline environments, ensuring a long service

life equivalent to the pipeline itself. Maintenance is straightforward—worn seals can be replaced by re-fastening

the flange or adding additional seal layers, extending usability without costly replacements.

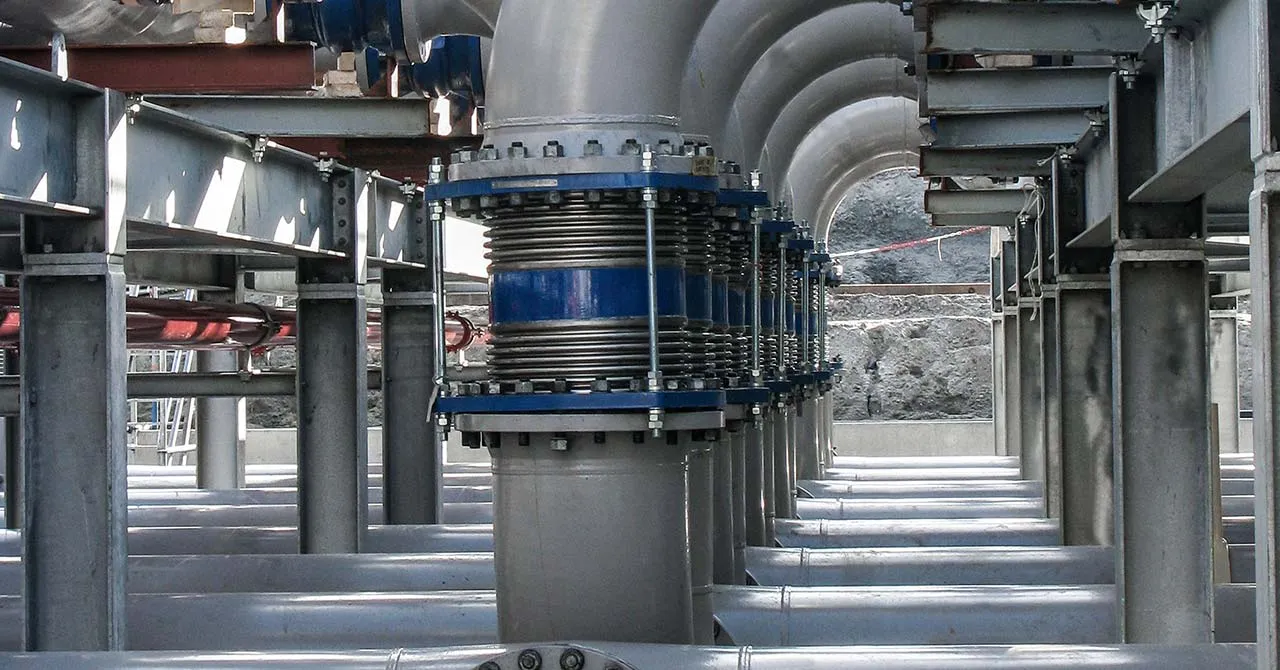

Compared to bellows-type expansion joints, sleeve compensators are simpler and more cost-effective

for axial movement, though they are less suited for lateral or angular displacements. They are ideal for hot water,

steam, and oil pipelines, with applications in district heating, municipal water projects, and industrial networks.

Installation is simplified with flanged, threaded, or welded ends, and proper anchoring ensures axial alignment.

Regular maintenance, such as tightening bolts after 24 hours of operation, enhances sealing performance and system

longevity.

Sleeve compensators address critical challenges like pipeline wear, thermal stress, and corrosion

in high-throughput systems. Their robust design, combined with corrosion resistance and

axial movement compensation, makes them a preferred choice for engineers seeking reliable,

low-maintenance solutions for industrial piping and boiler pipeline protection,

ensuring safety and efficiency in demanding environments.

FAQs

A sleeve compensator is a device for industrial piping, absorbing axial

movement with corrosion resistance.

Made from stainless steel, carbon steel, or copper with flexible graphite or EPDM seals for corrosion

resistance.

They provide axial movement compensation, reduce pipeline stress, and ensure durability in

high-pressure systems.

They comply with API 1102 and ASME Section VIII standards for industrial piping solutions.

Used in power plants, water supply, chemical processing, and boiler pipeline protection for

corrosion resistance and axial compensation.