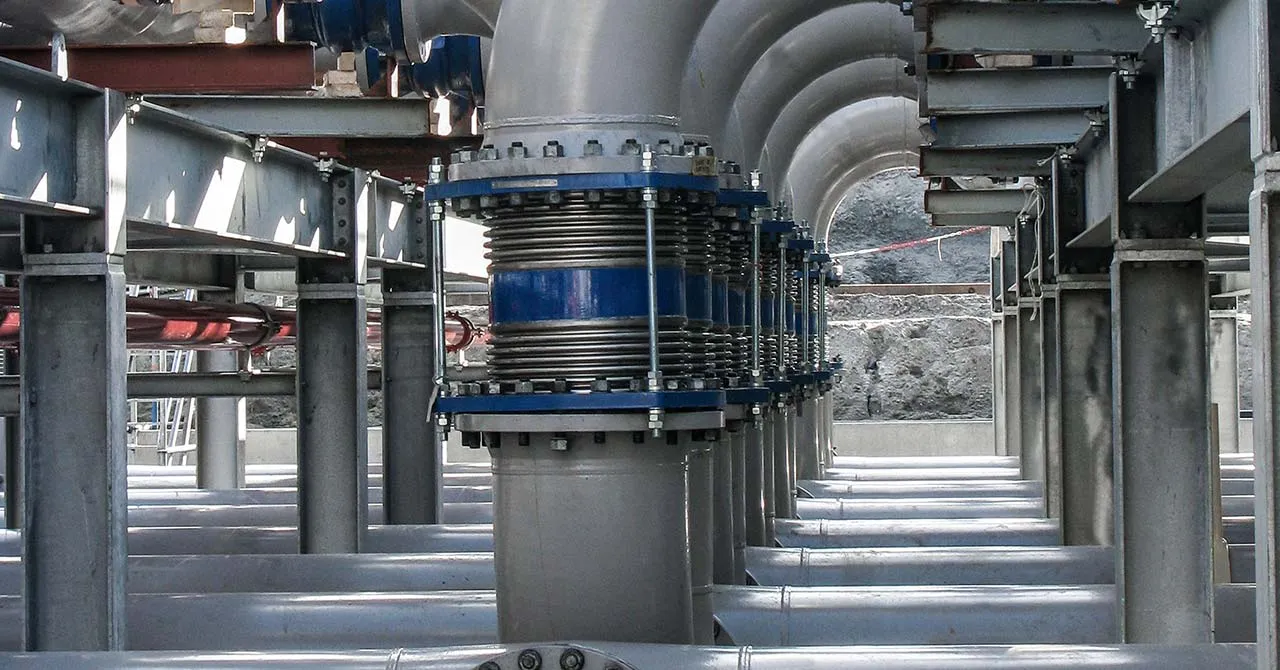

Flexible Expansion Joints are critical components in industrial piping

systems, designed to absorb thermal expansion, mechanical vibrations, and misalignment while

maintaining system integrity. Constructed from materials like stainless steel, rubber, or PTFE-lined

composites, these joints provide excellent corrosion resistance and flexibility, making

them ideal for applications in chemical processing, power generation, HVAC systems, and boiler

pipeline protection. Their versatile design ensures reliable performance under varying pressure

and temperature conditions.

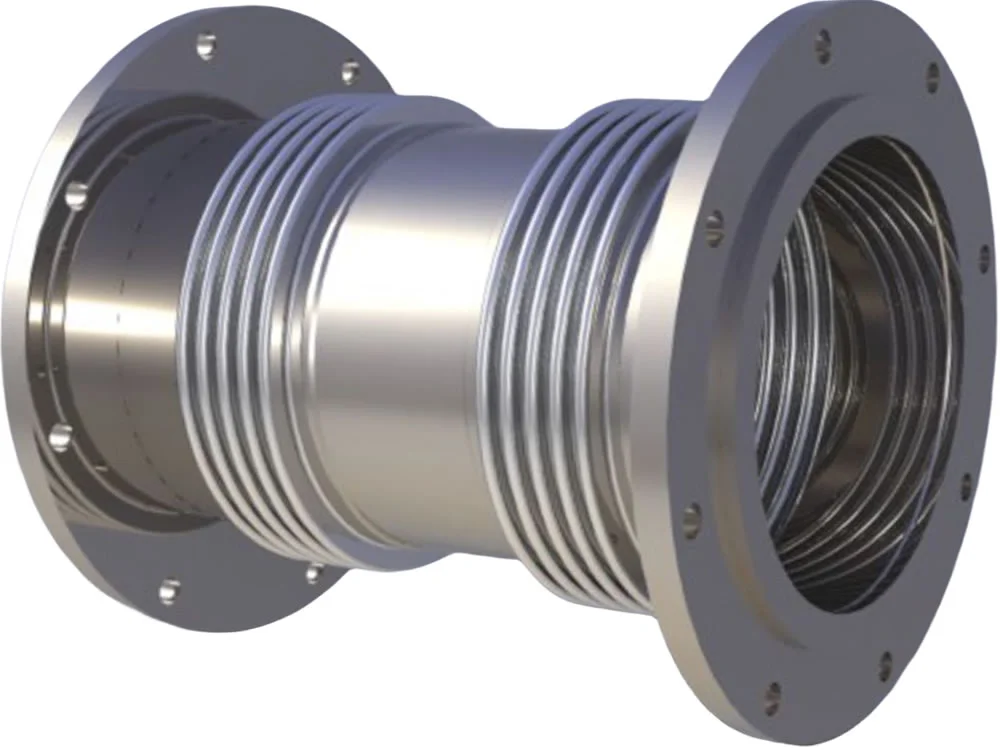

Available in sizes from 1” to 120” (DN25 to DN3000), flexible expansion joints handle

pressures up to 10 MPa and temperatures ranging from -50°C to 500°C, depending on the material and

configuration. They are available in configurations such as single, double, or universal joints,

accommodating axial, lateral, and angular movements. Compliant with standards like EJMA, ASME B31.3, and

ASTM F-1120, these joints ensure quality and safety in industrial piping solutions. The

choice of materials—stainless steel for high corrosion resistance, rubber for vibration damping, or PTFE for

chemical compatibility—caters to diverse industrial needs.

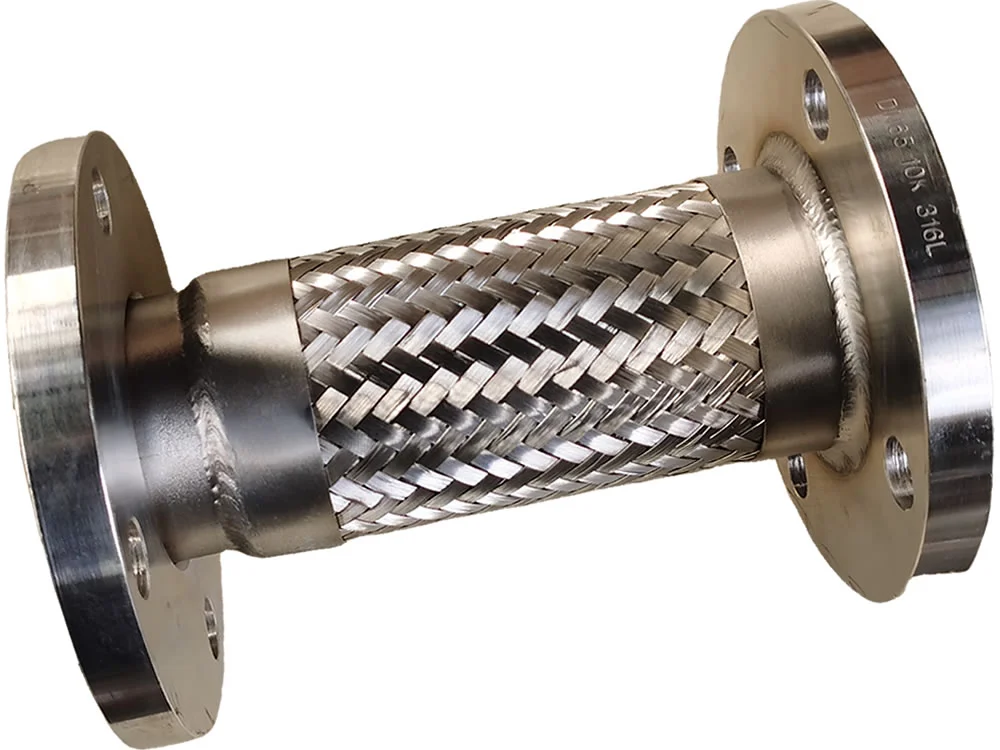

The corrosion resistance of flexible expansion joints, particularly those with stainless

steel or PTFE linings, makes them suitable for handling aggressive fluids, gases, and abrasive media in

industries like petrochemicals and wastewater treatment. Their vibration damping

capabilities protect critical equipment such as pumps, compressors, and turbines, reducing wear and

extending system lifespan. Features like tie rods, control units, and internal liners enhance performance in

high-velocity flows or extreme environments, while flanged, threaded, or welded ends simplify installation.

Compared to metallic bellows joints, flexible expansion joints with rubber or PTFE

components offer superior vibration absorption and are lighter, though they may have lower pressure ratings.

They are ideal for applications like steam lines, cooling systems, and chemical transfer pipelines. Rigorous

testing, including hydrostatic, burst, and fatigue tests, ensures reliability and compliance with industry

standards. Custom designs, such as multi-ply bellows or high-movement configurations, provide tailored

solutions for complex piping systems.

Flexible expansion joints address challenges like pipeline wear, corrosion, and thermal

stress in high-throughput industrial systems. Their corrosion-resistant, flexible design makes them a

preferred choice for engineers seeking reliable thermal expansion joints for demanding

environments, ensuring safety, efficiency, and longevity in applications like power plants, refineries, and

HVAC systems.

What is a flexible material for expansion joints?

Using rubber in expansion joints offers several advantages over other materials. Not only are they

flexible and high strength, but they are durable and able to resist thermal expansion and contraction

more than other materials.

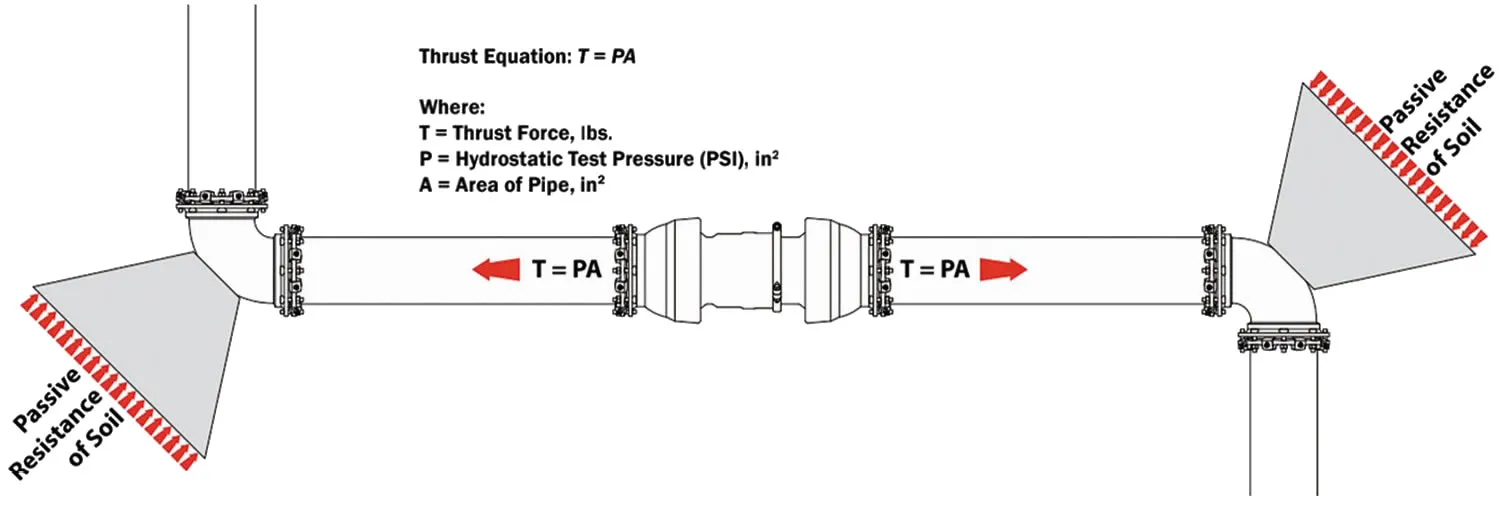

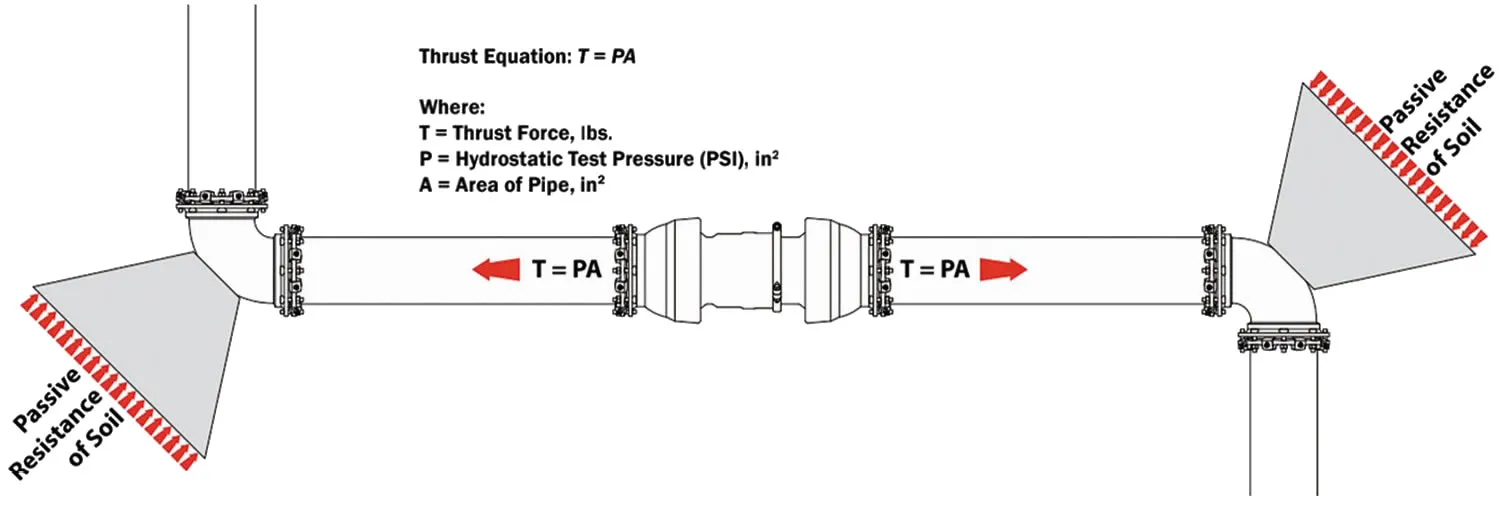

Flexible expansion joints behave similarly to other expansion joints under pressure. Due to their design,

expansion joints generate end thrust when subject to internal pressure, as seen in Figure 1.1. This end

thrust must be accounted for in pipeline design. The end thrust generated is calculated by multiplying

internal pressure (PSI) by the area listed in Table 1.1.

When used in a long and relatively straight pipeline, the pipe-to-soil friction is generally sufficient

to balance the force. The use of thrust blocks or other means of anchoring is required when fittings are

placed in close proximity to the expansion joint underground. This protects the pipeline from the

tendency of the unit to expand when pressurized. In an above-ground installation such as a bridge

application, some means must be provided to prevent the expansion of bridge application, some

Thrust calculations | Units: inch, inch², lb)

| Size (inch) |

Area (inch²) |

Thrust@150 PSI (lb) |

| 2 |

4.43 |

664.5 |

| 3 |

12.3 |

1845 |

| 4 |

18.1 |

2715 |

| 6 |

37.4 |

5610 |

| 8 |

64.3 |

9645 |

| 10 |

96.8 |

14520 |

| 12 |

136.9 |

20535 |

| 14 |

237.8 |

35670 |

| 16 |

237.8 |

35670 |

| 18 |

366.4 |

54960 |

| 20 |

366.4 |

54960 |

| 24 |

522.8 |

78420 |

| 30 |

804.3 |

120645 |

| 36 |

1152.1 |

175815 |

| 42 |

1555.3 |

233295 |

| 48 |

2027 |

304050 |

The successful installation of expansion joints in a pipe system Requires the careful consideration of

many variables. The most important issue is to establish the direction in which the movements are acting

and in which way the movements should be absorbed. Once this information is known, the solution

incorporating the most suitable expansion joint type(s) can be determined. The following pages give some

ideas and suggestions for a pipe system design, and how to implement expansion joints in the system in

the Best way.