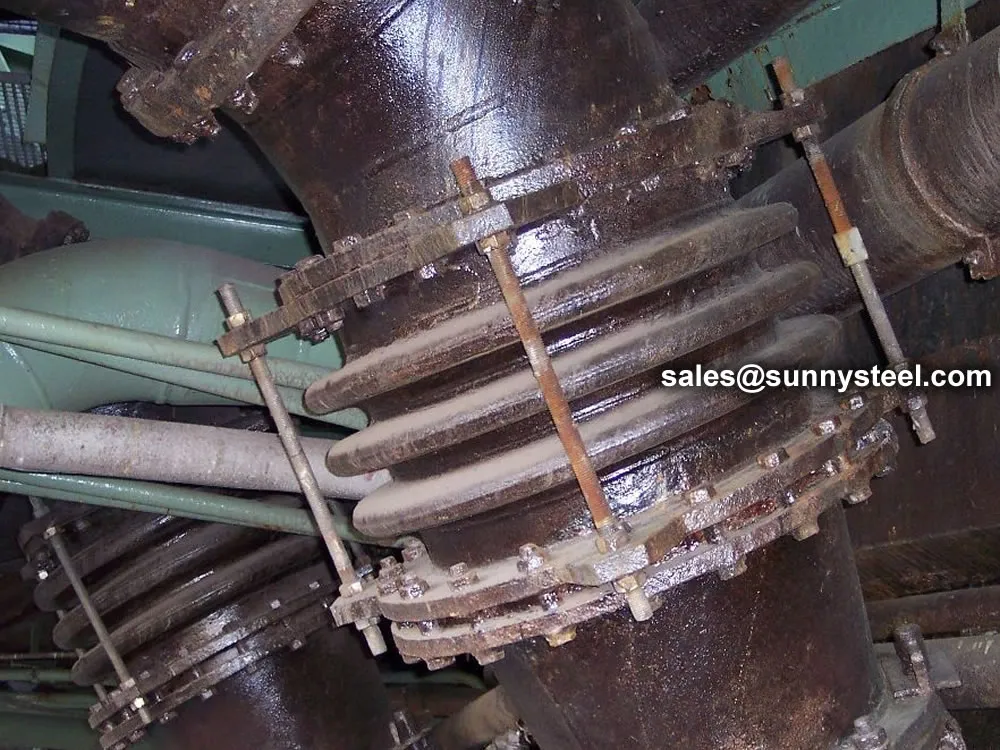

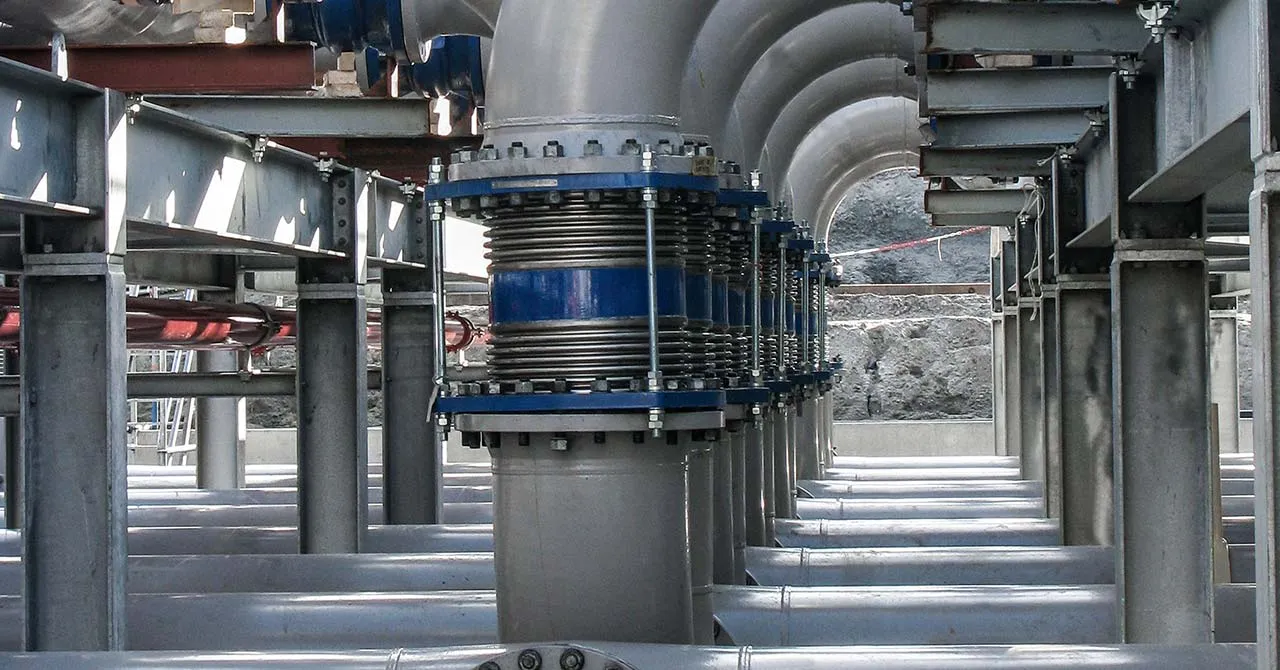

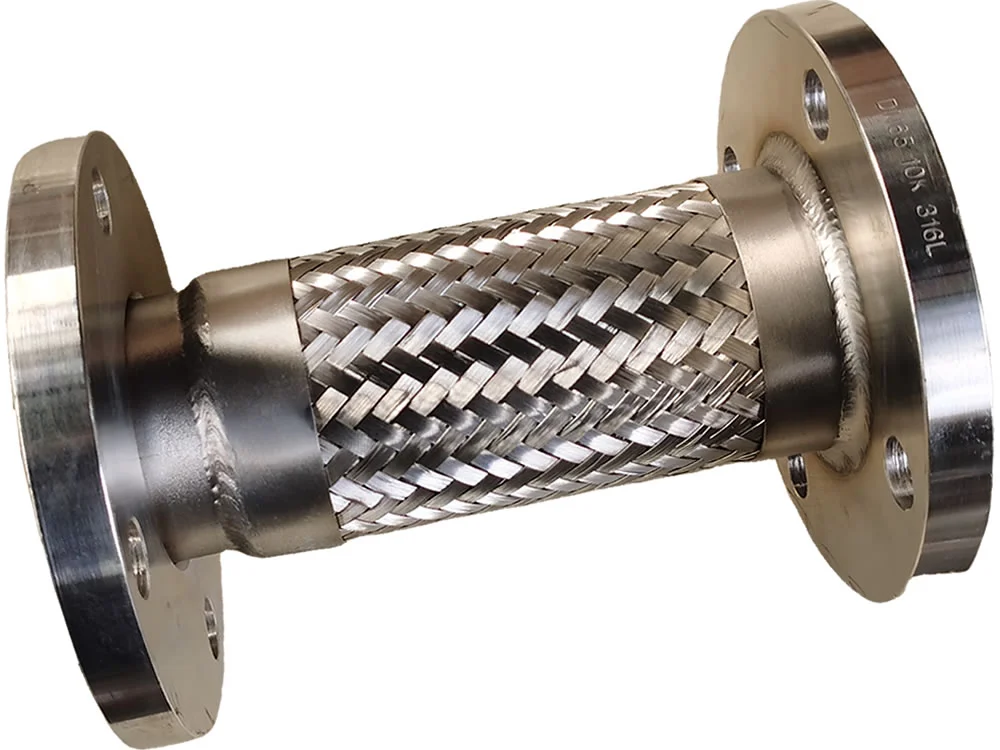

Bellows Expansion Joints are essential components in industrial piping systems, engineered to absorb thermal expansion, mechanical vibrations, and misalignment while ensuring system integrity. Typically constructed from stainless steel, high-grade nickel alloys, or PTFE-lined materials, these joints provide superior corrosion resistance and flexibility, making them ideal for demanding applications in chemical processing, power generation, oil and gas, and boiler pipeline protection. Their robust design ensures reliable performance under extreme pressure and temperature conditions.

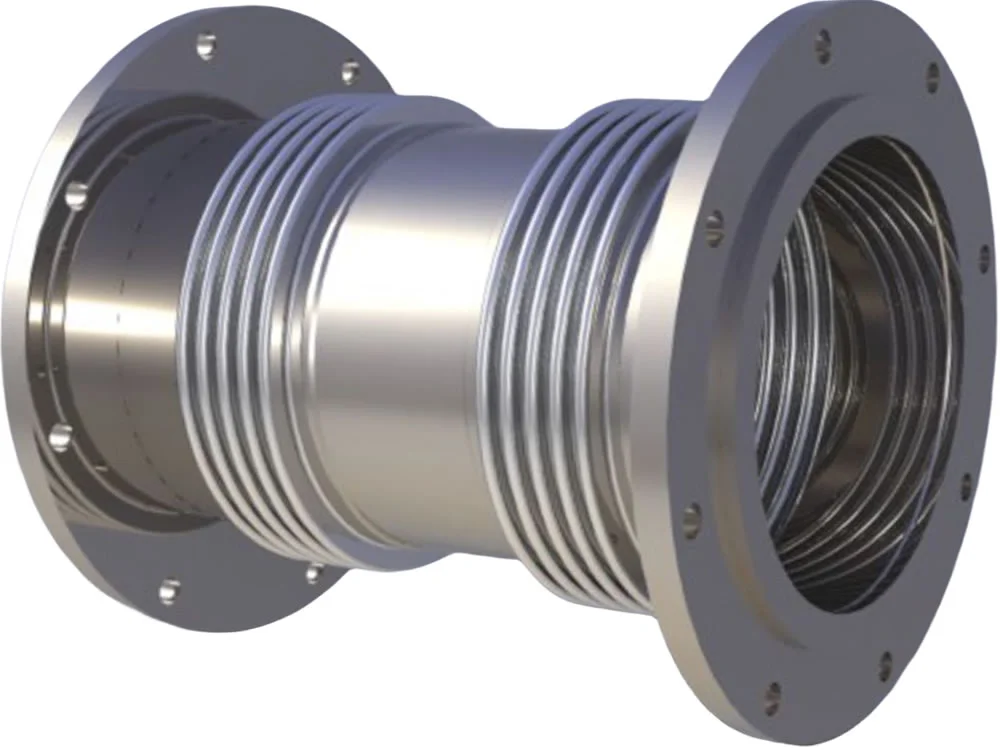

Available in sizes ranging from 1” to 120” (DN25 to DN3000), bellows expansion joints can handle pressures up to 10 MPa and temperatures from -50°C to 600°C, depending on the material and configuration. They are designed in various types, including single, universal, hinged, and gimbal, to accommodate axial, lateral, and angular movements. Compliant with standards such as EJMA, ASME B31.3, and ASTM F-1120, these joints ensure quality, safety, and durability in industrial piping solutions. Materials like stainless steel (SS304, SS316, SS321) or Inconel provide excellent resistance to corrosion and high-temperature environments.

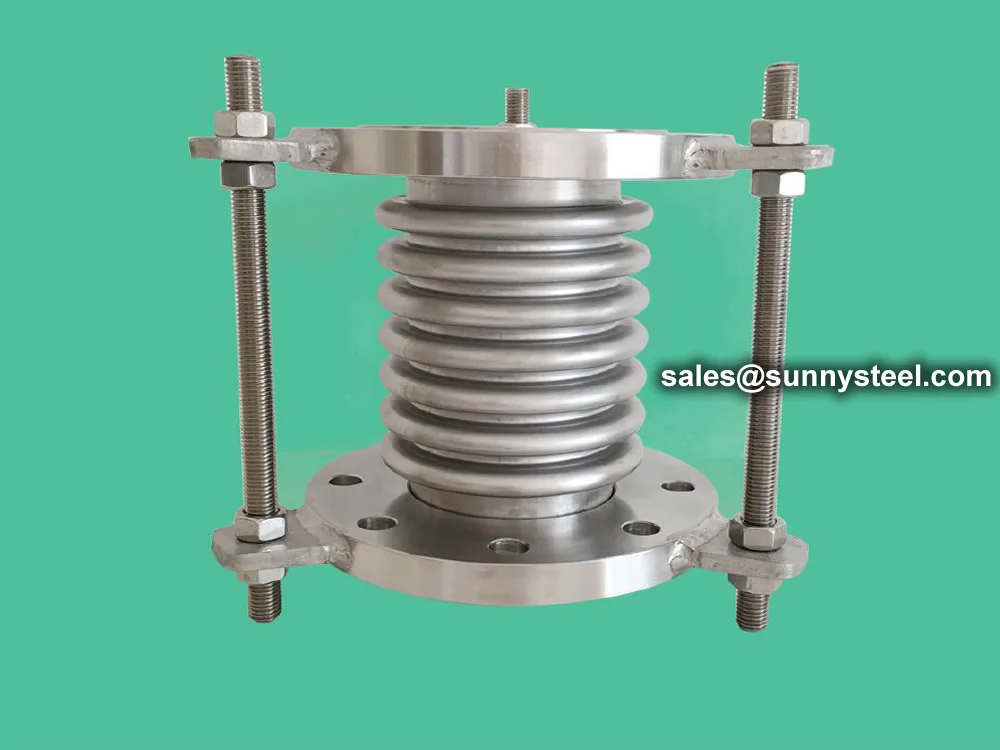

The corrosion resistance of bellows expansion joints makes them suitable for handling aggressive fluids, gases, and abrasive media in industries such as petrochemicals, wastewater treatment, and power plants. Their vibration damping properties protect critical equipment like pumps, compressors, and turbines, reducing wear and extending operational life. Features such as tie rods, control units, and internal flow liners enhance performance in high-velocity or turbulent flow conditions, while flanged, welded, or threaded end connections facilitate easy installation.

Compared to rubber or composite expansion joints, bellows expansion joints excel in high-pressure and high-temperature applications due to their metallic construction, though they may offer less vibration absorption in low-pressure systems. They undergo rigorous testing, including hydrostatic, pneumatic, and fatigue tests, to ensure compliance with industry standards. Custom configurations, such as multi-ply bellows or pressure-balanced designs, provide tailored solutions for complex piping systems, addressing specific project requirements.

Bellows expansion joints effectively mitigate challenges like pipeline wear, corrosion, and thermal stress in high-throughput industrial systems. Their corrosion-resistant and durable design makes them a preferred choice for engineers seeking reliable thermal expansion joints for extreme environments, ensuring safety, efficiency, and longevity in applications like refineries, boiler systems, and HVAC installations.

Chemical Composition of Common Materials

| Element |

Stainless Steel (SS316L) (%) |

Inconel 625 (%) |

| Carbon (C) |

≤0.03 |

≤0.10 |

| Chromium (Cr) |

16.0-18.0 |

20.0-23.0 |

| Nickel (Ni) |

10.0-14.0 |

≥58.0 |

| Molybdenum (Mo) |

2.0-3.0 |

8.0-10.0 |

| Iron (Fe) |

Balance |

≤5.0 |

| Other |

Mn, Si, P, S |

Nb, Ti, Al |

Mechanical Properties of Bellows Expansion Joints

| Property |

Value |

| Tensile Strength (MPa) |

515-690 (SS316L); 827-1034 (Inconel 625) |

| Yield Strength (MPa) |

205 (SS316L); 414 (Inconel 625) |

| Elongation (%) |

≥40 (SS316L); ≥30 (Inconel 625) |

| Pressure Rating (MPa) |

Up to 10 |

| Temperature Range (°C) |

-50 to 600 |

Stainless steel bellows, as a flexible pressure-resistant pipe fittings, are installed in the liquid transportation system to compensate for the mutual displacement of the connecting ends of pipes or machines and equipment, absorb vibration energy, and can play the role of vibration reduction and silencing. They have many characteristics, such as good flexibility, light weight, corrosion resistance, fatigue resistance, high and low temperature resistance.

Bellows Expansion Joint Axial Compensation & Performance Parameters

(Pressure: MPa; Axial Compensation: mm; Toughness: N/mm; Effective Area: cm²; Diameter: mm)

| DN |

Quantity of ripple |

Pressure level (MPa) |

Effective area of corrugated tube (cm²) |

Maximum external diameter (mm) |

| 0.25 |

0.6 |

1.0 |

1.6 |

2.5 |

| Axial compensation length / Toughness (mm / N/mm) |

| 32 | 8 | 25/21 | 22/26 | 20/26 | 18/63 | - | 16 | 225 |

| 32 | 16 | 50/11 | 46/14 | 41/14 | 36/32 | - | 16 | 225 |

| 40 | 8 | 25/25 | 22/44 | 20/44 | 18/89 | 15/98 | 23 | 244 |

| 40 | 16 | 50/14 | 46/22 | 41/22 | 36/45 | 31/47 | 23 | 244 |

| 50 | 8 | 25/30 | 22/51 | 20/70 | 18/70 | 15/106 | 37 | 259 |

| 50 | 16 | 50/16 | 46/26 | 41/35 | 36/35 | 31/55 | 37 | 259 |

| 65 | 8 | 33/28 | 30/35 | 26/44 | 22/55 | 15/138 | 55 | 270 |

| 65 | 12 | 42/16 | 38/22 | 38/32 | 34/40 | 31/70 | 55 | 270 |

| 80 | 8 | 40/20 | 36/26 | 34/33 | 28/41 | 19/68 | 81 | 284 |

| 80 | 10 | 53/14 | 49/17 | 49/21 | 43/26 | 29/50 | 81 | 284 |

| 100 | 6 | 45/47 | 45/60 | 40/75 | 35/93 | 25/54 | 121 | 304 |

| 100 | 10 | 76/26 | 74/32 | 64/40 | 57/50 | 38/33 | 121 | 304 |

| 125 | 5 | 48/38 | 42/47 | 38/59 | 34/74 | 29/117 | 180 | 334 |