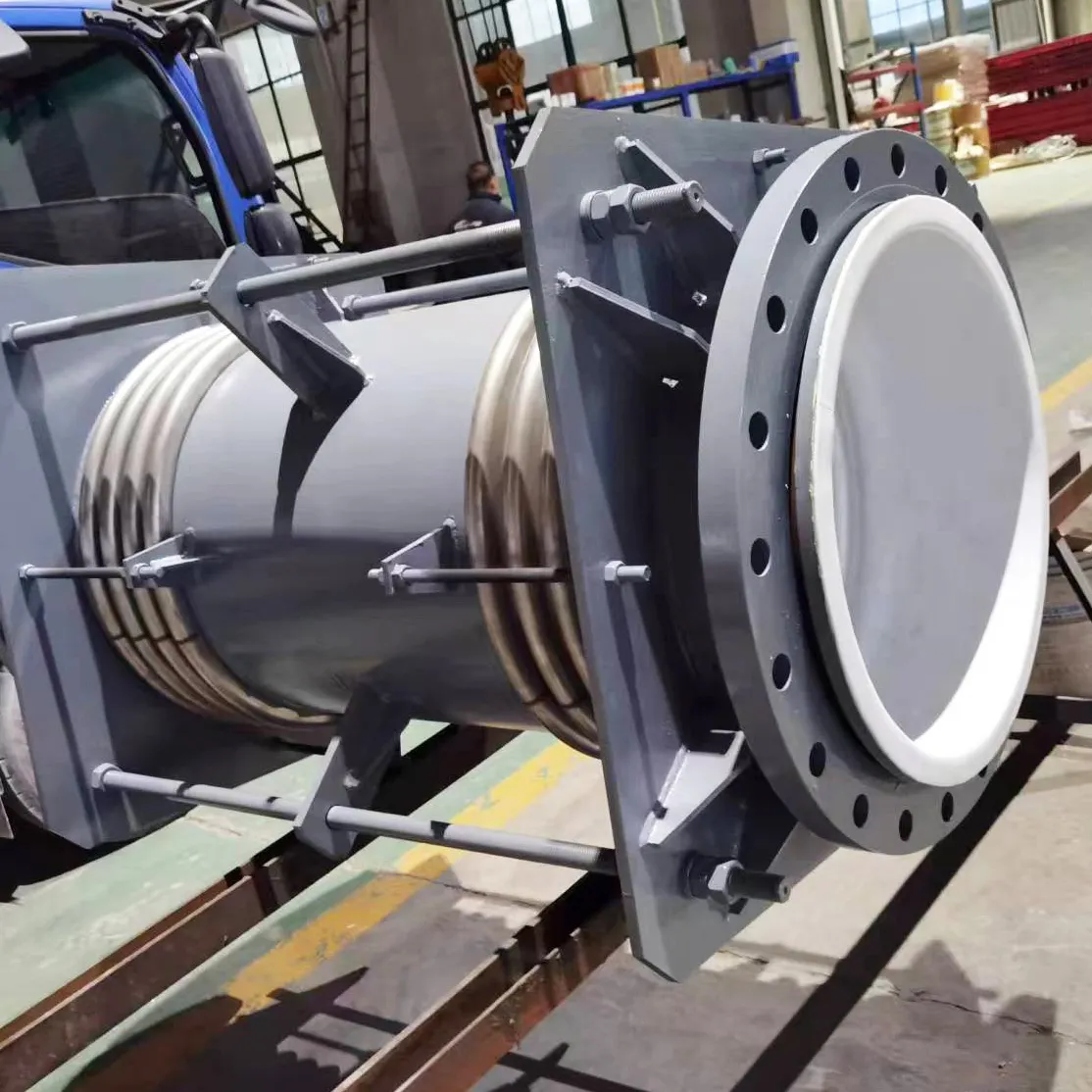

PTFE-Lined Rubber Expansion Joints are critical components in industrial piping

systems, designed to combine the flexibility of rubber with the superior corrosion

resistance of PTFE (Polytetrafluoroethylene). These joints are engineered to absorb thermal

expansion, mechanical vibrations, and misalignment while ensuring durability in highly corrosive

environments, such as chemical processing, petrochemical plants, and boiler pipeline

protection. The PTFE lining protects against aggressive chemicals, while the rubber exterior

provides excellent vibration damping and flexibility.

Available in sizes from 1” to 120” (DN25 to DN3000), PTFE-lined rubber expansion joints can

operate at pressures up to 2 MPa and temperatures from -10°C to 204°C, depending on the configuration and

elastomer used (e.g., EPDM, Neoprene, or Nitrile). Compliant with standards like ANSI/NSF 61 and EJMA, these

joints ensure reliability and safety in industrial piping solutions. The PTFE liner, often

seamless and isostatically molded, covers all wetted surfaces, providing resistance to a wide range of

corrosive fluids, including acids, alkalis, and solvents.

The corrosion resistance of PTFE makes these joints ideal for handling aggressive media in

industries such as pharmaceuticals, pulp and paper, and wastewater treatment. The rubber component,

reinforced with woven polyester or Kevlar, enhances pressure resistance and vibration

damping, protecting equipment like pumps and compressors from stress and noise. Features like

control units, tie rods, and flanged or threaded ends ensure easy installation and compatibility with

various piping systems. The joints can accommodate axial, lateral, and angular movements, making them

versatile for complex installations.

Compared to metallic bellows expansion joints, PTFE-lined rubber expansion joints offer

superior flexibility and noise reduction but are limited to lower pressure and temperature ranges. They

undergo rigorous testing, including hydrostatic and burst tests, to ensure compliance with industry

standards. Optional features like Hypalon coatings or stainless steel retaining rings enhance durability in

harsh environments. These joints are particularly suited for applications requiring compact designs, such as

HVAC systems or glass-lined piping, where space is limited.

PTFE-lined rubber expansion joints address critical challenges like pipeline wear,

corrosion, and thermal stress in industrial systems. Their unique combination of PTFE’s chemical inertness

and rubber’s elasticity makes them a cost-effective, reliable choice for engineers seeking durable

chemical piping protection in extreme conditions, ensuring longevity and safety in

demanding applications like refineries and chemical

plants.

Chemical Composition of PTFE and Common Elastomers

| Material |

Main Components |

| PTFE (Liner) |

Polytetrafluoroethylene (C2F4)n |

| EPDM (Rubber) |

Ethylene, Propylene, Diene Monomer |

| Neoprene |

Chloroprene, Carbon, Hydrogen |

| Nitrile |

Butadiene, Acrylonitrile |

| Reinforcement |

Polyester, Kevlar, or Steel Wire |

Mechanical Properties of PTFE-Lined Rubber Expansion Joints

| Property |

Value |

| Tensile Strength (MPa) |

10-20 (Rubber); PTFE: 20-30 |

| Elongation (%) |

200-600 (Rubber); PTFE: 100-400 |

| Pressure Rating (MPa) |

Up to 2 |

| Temperature Range (°C) |

-10 to 204 |

| Hardness (Shore A) |

50-70 (Rubber) |

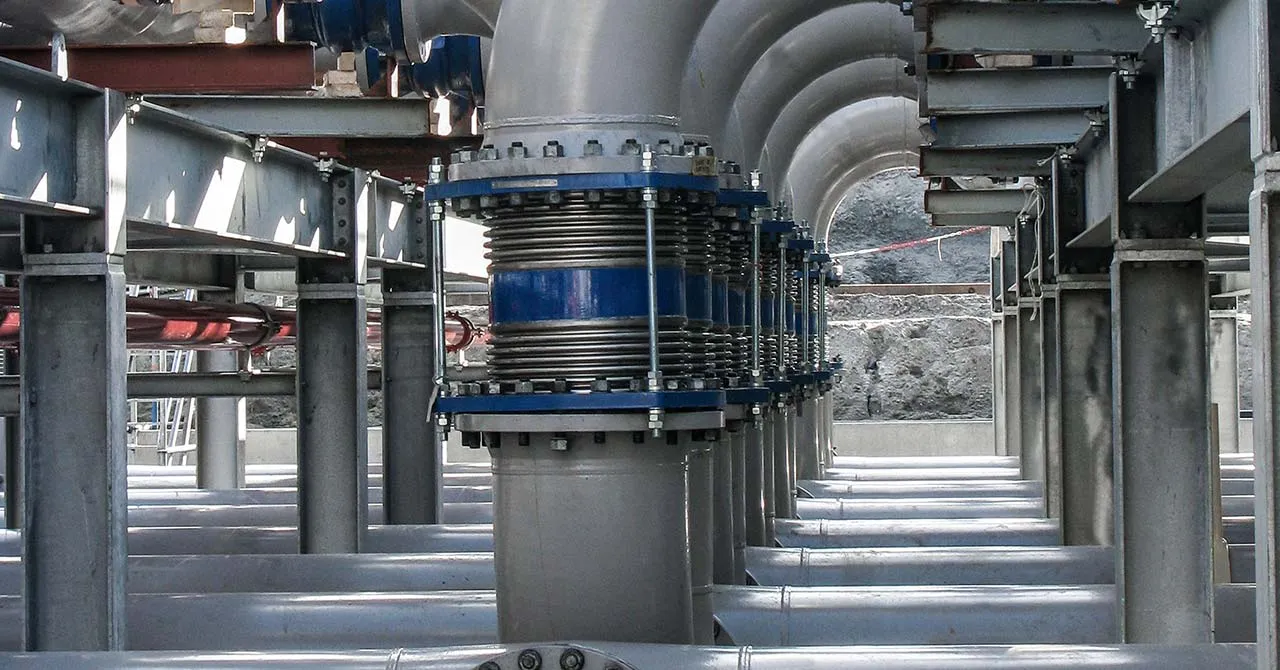

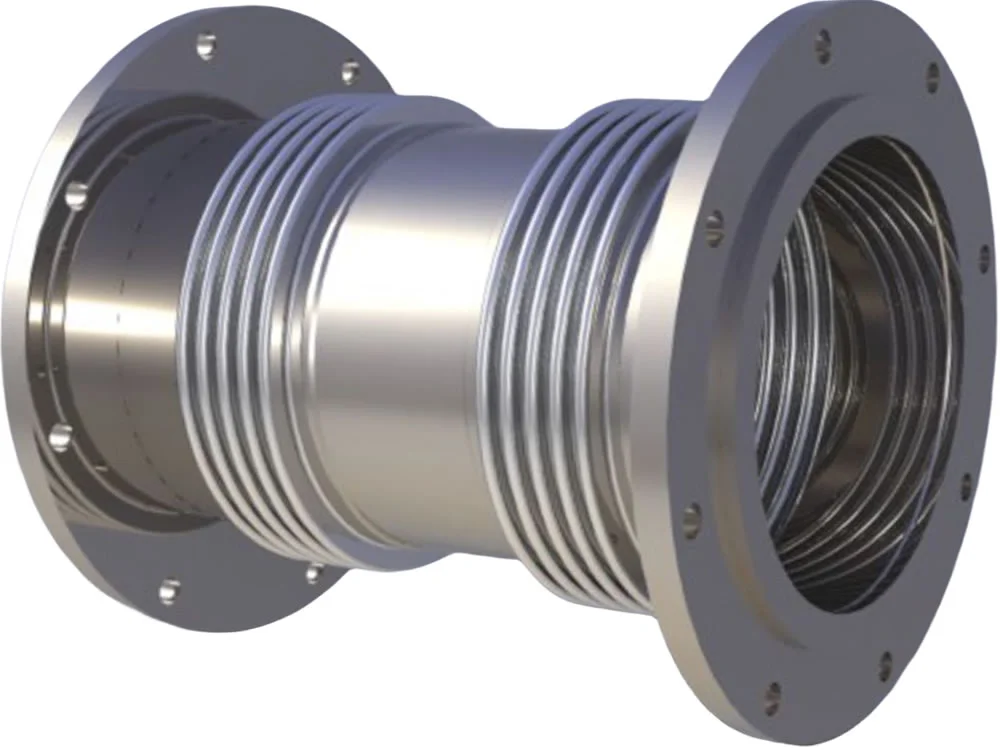

Stainless steel bellows, as a flexible pressure-resistant pipe fittings, are installed in the liquid

transportation system to compensate for the mutual displacement of the connecting ends of pipes or

machines and equipment, absorb vibration energy, and can play the role of vibration reduction and

silencing. They have many characteristics, such as good flexibility, light weight, corrosion resistance,

fatigue resistance, high and low temperature resistance.

Bellows Expansion Joint Axial Compensation & Performance Parameters

(Pressure: MPa; Axial Compensation: mm; Toughness: N/mm; Effective Area: cm²; Diameter: mm)

| DN |

Quantity of ripple |

Pressure level (MPa) |

Effective area of corrugated tube (cm²) |

Maximum external diameter (mm) |

| 0.25 |

0.6 |

1.0 |

1.6 |

2.5 |

| Axial compensation length / Toughness (mm / N/mm) |

| 32 |

8 |

25/21 |

22/26 |

20/26 |

18/63 |

- |

16 |

225 |

| 32 |

16 |

50/11 |

46/14 |

41/14 |

36/32 |

- |

16 |

225 |

| 40 |

8 |

25/25 |

22/44 |

20/44 |

18/89 |

15/98 |

23 |

244 |

| 40 |

16 |

50/14 |

46/22 |

41/22 |

36/45 |

31/47 |

23 |

244 |

| 50 |

8 |

25/30 |

22/51 |

20/70 |

18/70 |

15/106 |

37 |

259 |

| 50 |

16 |

50/16 |

46/26 |

41/35 |

36/35 |

31/55 |

37 |

259 |

| 65 |

8 |

33/28 |

30/35 |

26/44 |

22/55 |

15/138 |

55 |

270 |

| 65 |

12 |

42/16 |

38/22 |

38/32 |

34/40 |

31/70 |

55 |

270 |

| 80 |

8 |

40/20 |

36/26 |

34/33 |

28/41 |

19/68 |

81 |

284 |

| 80 |

10 |

53/14 |

49/17 |

49/21 |

43/26 |

29/50 |

81 |

284 |

| 100 |

6 |

45/47 |

45/60 |

40/75 |

35/93 |

25/54 |

121 |

304 |

| 100 |

10 |

76/26 |

74/32 |

64/40 |

57/50 |

38/33 |

121 |

304 |

| 125 |

5 |

48/38 |

42/47 |

38/59 |

34/74 |

29/117 |

180 |

334 |