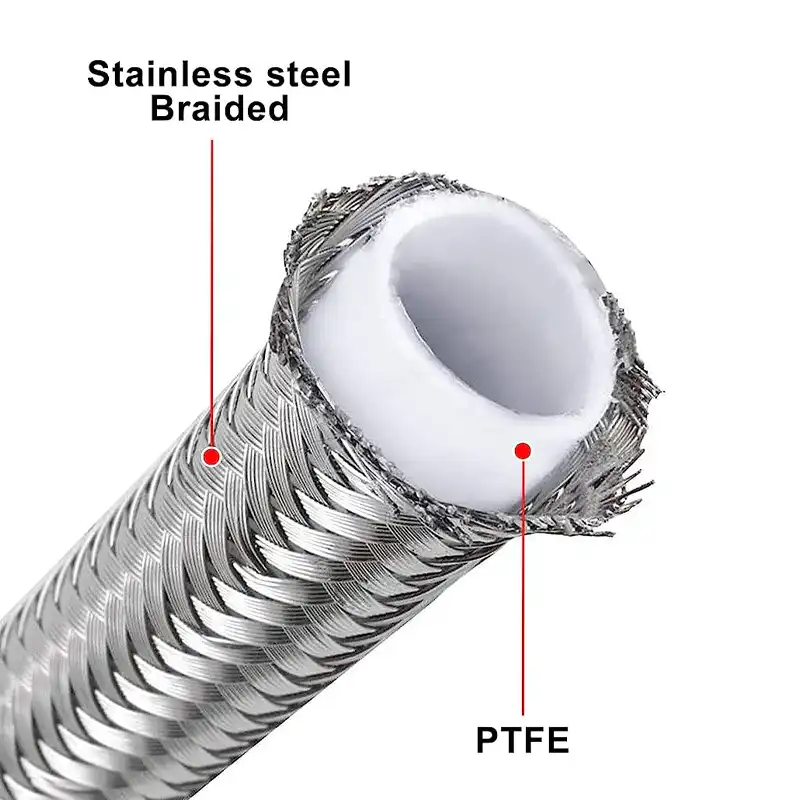

PTFE-Lined Flexible Hoses are engineered for industrial piping solutions, combining the exceptional corrosion resistance of PTFE (Polytetrafluoroethylene) with the flexibility of braided or convoluted hose designs. These hoses are ideal for demanding applications in chemical processing, pharmaceuticals, food and beverage, and power generation, where they handle aggressive fluids, high temperatures, and pressures while providing vibration damping. The PTFE liner ensures chemical inertness, preventing contamination and ensuring safe fluid transfer.

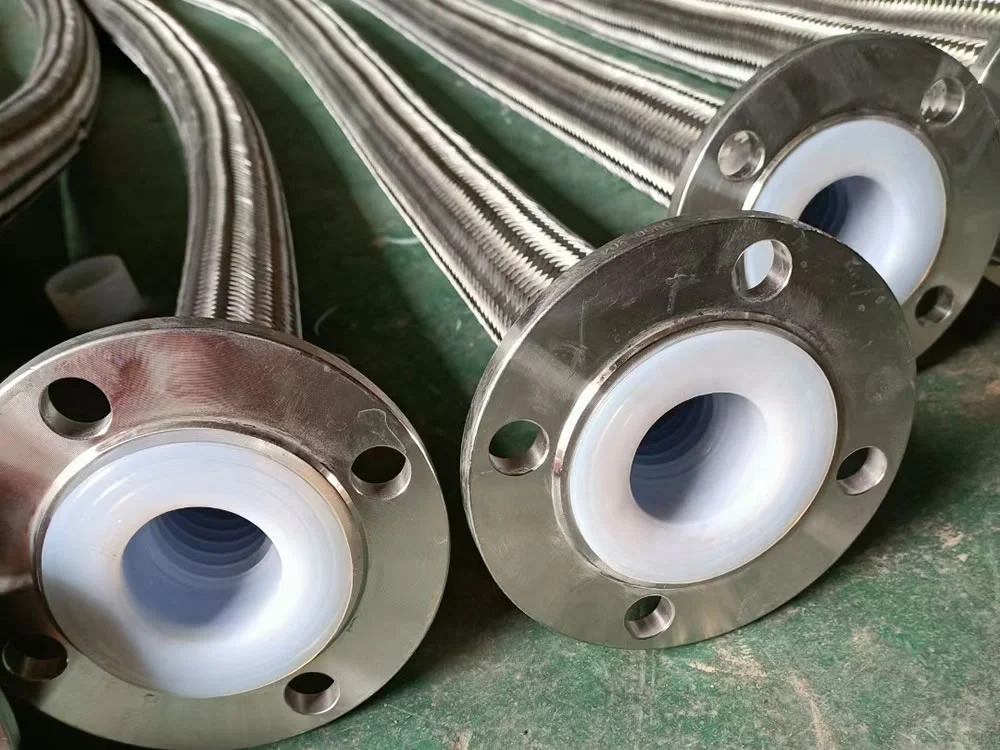

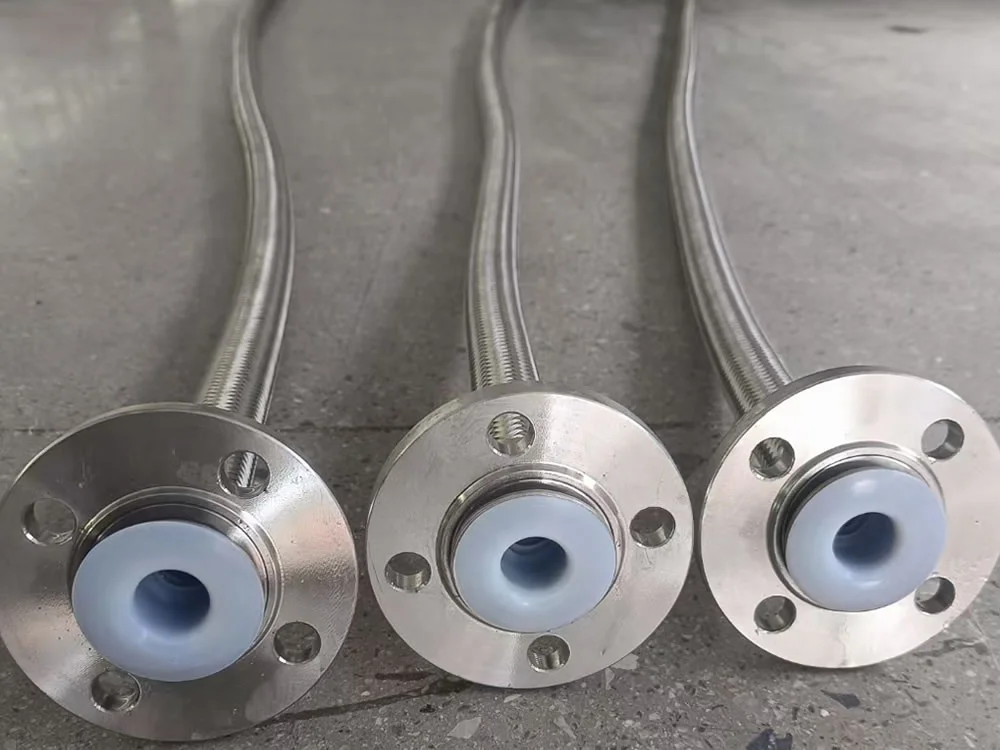

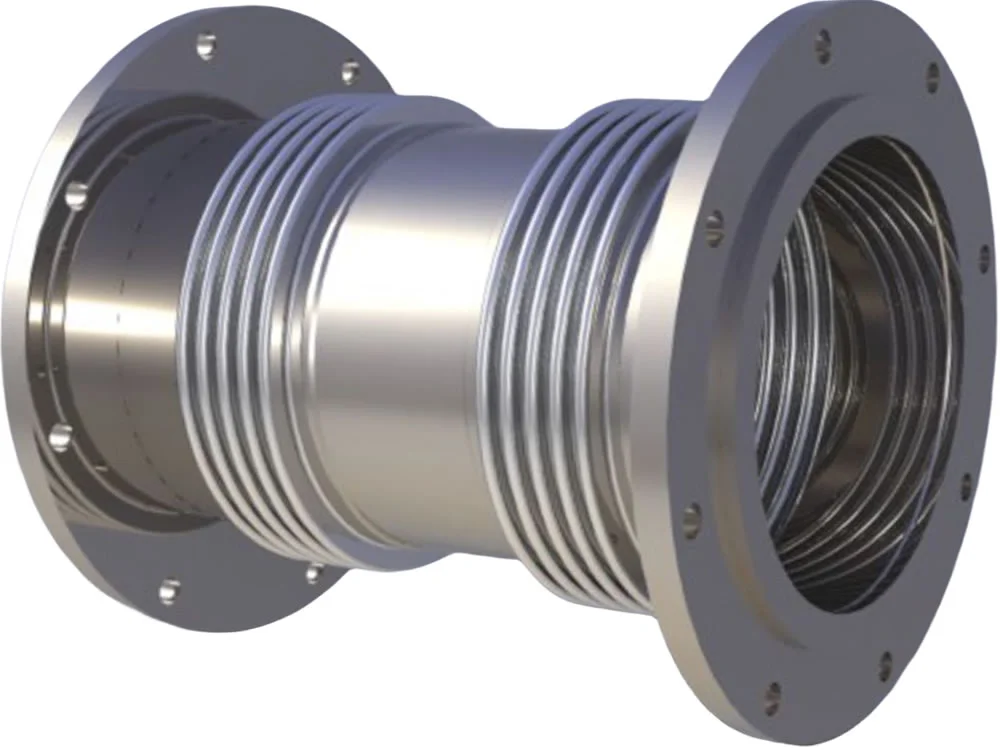

Available in sizes from 1/4” to 6” (DN6 to DN150), PTFE-lined flexible hoses operate at pressures up to 6000 PSI (41 MPa) and temperatures from -65°F to 450°F (-54°C to 232°C), depending on the configuration. Compliant with standards like FDA, USP Class VI, and ISO, these hoses feature a smooth or convoluted PTFE core, often reinforced with stainless steel, nylon, or polypropylene braiding for enhanced strength and flexibility. The smooth bore ensures fast, clean flow, while convoluted designs offer superior flexibility for tight spaces.

The corrosion resistance of PTFE makes these hoses perfect for handling acids, alkalis, solvents, and other aggressive media, outperforming rubber or silicone hoses in chemical transfer applications. Their non-stick properties facilitate easy cleaning, meeting stringent hygiene standards in pharmaceutical and food industries. Features like static-dissipative liners prevent static buildup in high-flow applications, while stainless steel braiding provides abrasion resistance and durability. These hoses are suitable for high-purity fluid transfer, compressed gas, and applications requiring resistance to fuel vapor permeation.

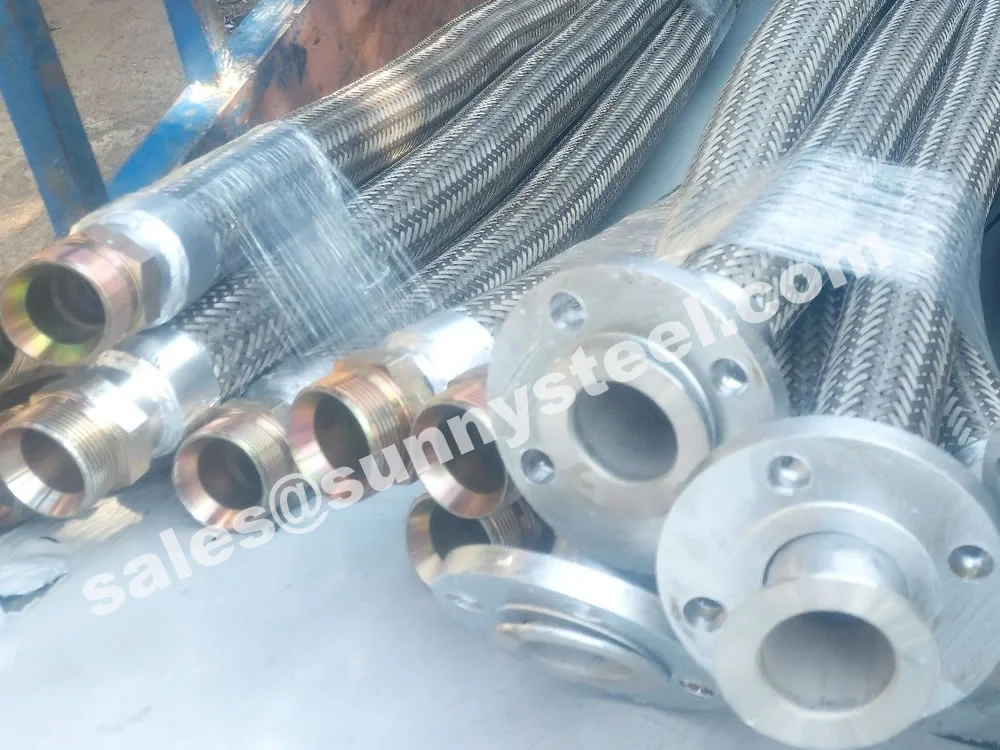

Compared to metallic hoses, PTFE-lined flexible hoses offer greater flexibility and lighter weight, though they may have lower pressure ratings than high-pressure metallic bellows. They undergo rigorous testing, including hydrostatic, burst, and fatigue tests, to ensure compliance with industry standards. Custom options like flared-through fittings, silicone covers, or conductive black PTFE liners enhance performance in specific applications, such as chlorine transfer or biopharmaceutical fluid handling.

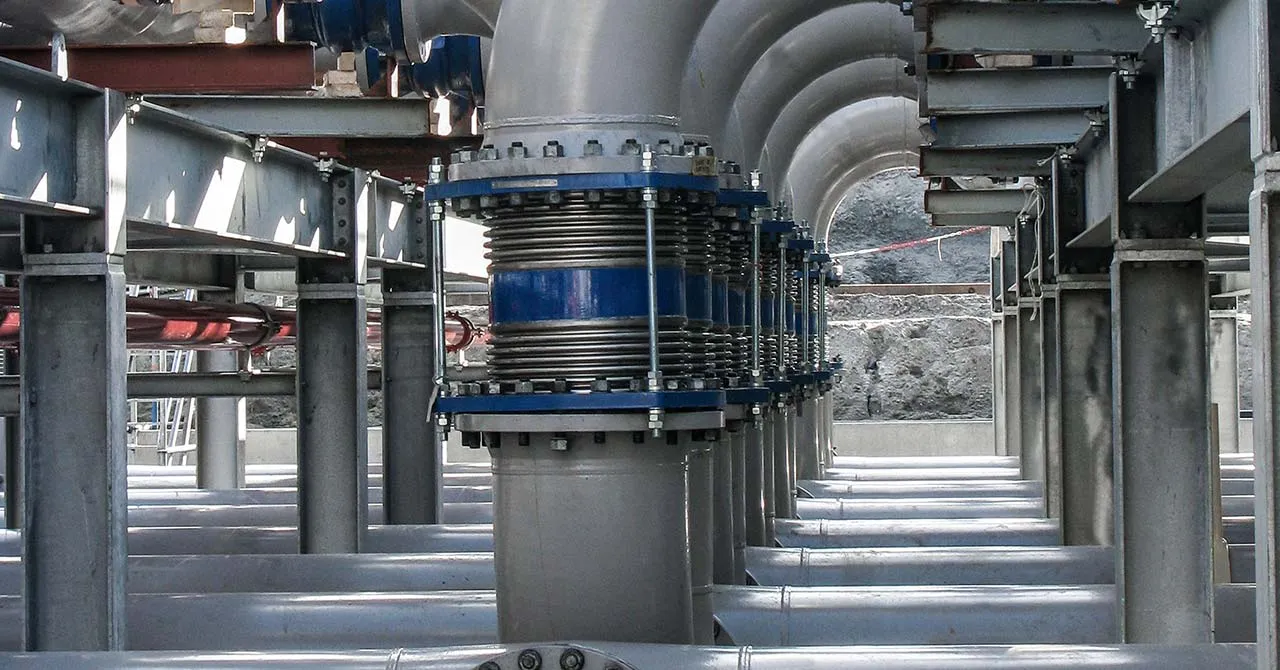

PTFE-lined flexible hoses address challenges like pipeline corrosion, vibration, and thermal expansion in industrial systems. Their robust construction and chemical inertness make them a reliable choice for engineers seeking durable chemical transfer hoses for extreme environments, ensuring safety, efficiency, and longevity in applications like refineries, autoclaves, and high-purity fluid systems.

PTFE Lined Hose

A PTFE lined hose represents an ideal solution for a diverse array of industrial and commercial applications.

Engineered to deliver outstanding performance and longevity, our PTFE lined hose boasts a multitude of advantages, establishing itself as the preferred choice for professionals across various industries.

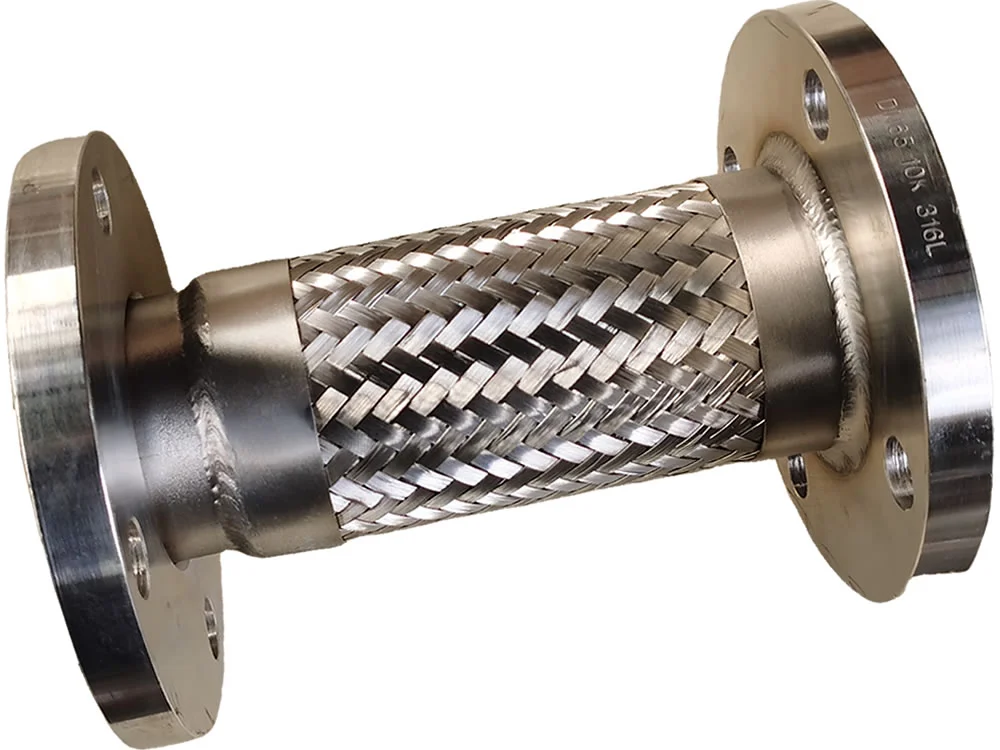

- Inner Tube: Seamless black conductive convoluted PTFE

- Cover: Braided stainless steel

- Temperature Range: -20°F to 350°F