Corrosion-resistant Hoses With Loose Flanges For Easy Installation

Flanged loose sleeve metal hoses, flexible piping solutions, corrosion resistance, vibration damping, high-pressure hoses, stainless steel hoses

Corrosion-resistant Hoses With Loose Flanges For Easy Installation

Flanged loose sleeve metal hoses, flexible piping solutions, corrosion resistance, vibration damping, high-pressure hoses, stainless steel hoses

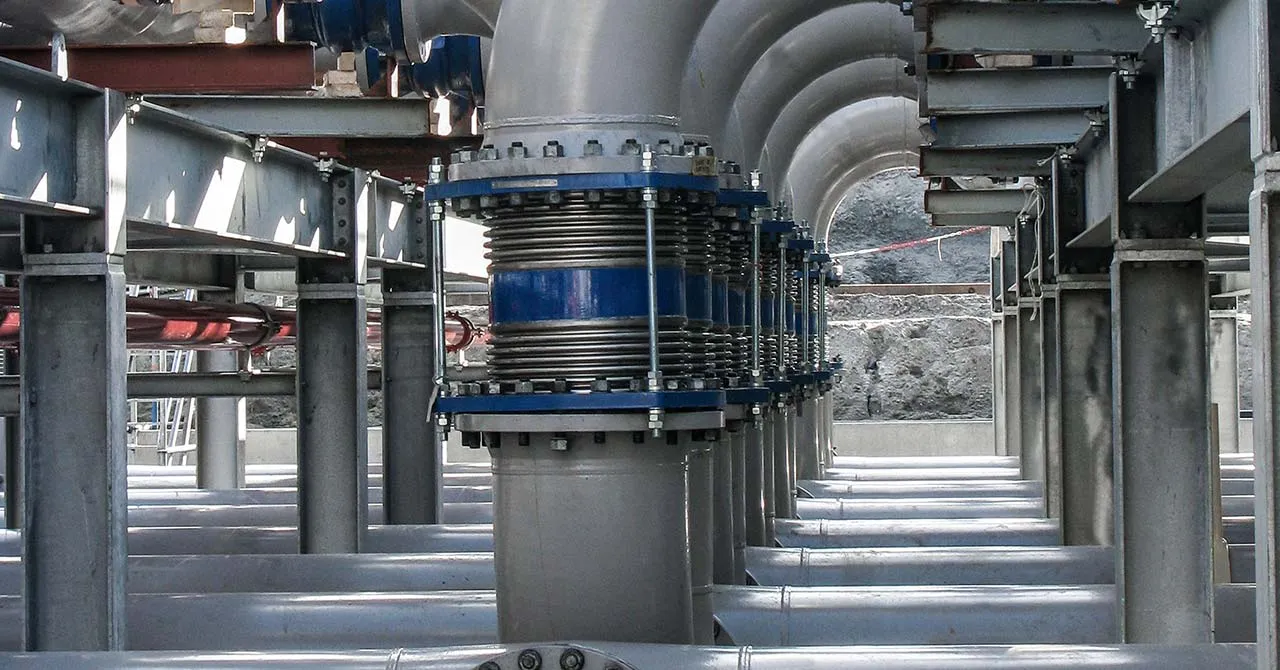

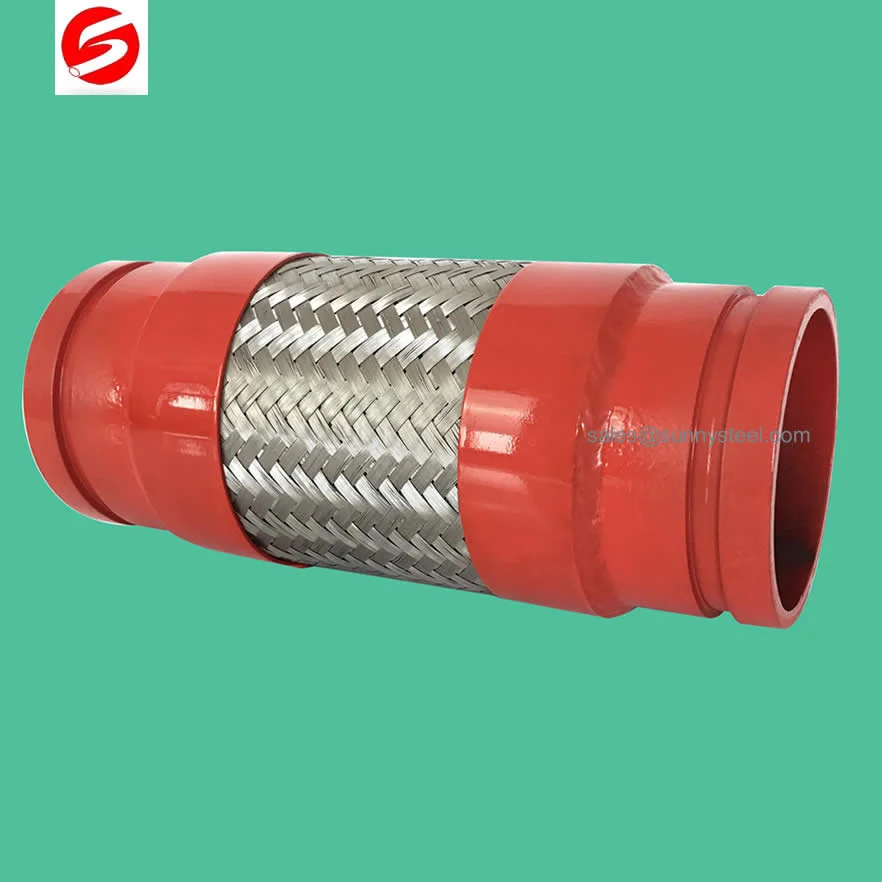

Flanged Loose Sleeve Metal Hoses are designed for flexible piping solutions, featuring a unique loose flange design that simplifies installation and maintenance in industrial piping systems. Constructed from high-quality stainless steel (304, 316, or 321), these hoses provide exceptional corrosion resistance and durability, making them ideal for applications in chemical processing, oil and gas, water treatment, and HVAC systems. The loose flange, sleeved over the pipe end, allows for easy alignment and movement without compromising the seal, enhancing vibration damping and flexibility.

Available in sizes from 2” to 14” (DN50 to DN350), flanged loose sleeve metal hoses operate at pressures up to 1500 PSI (10.3 MPa) and temperatures from -200°C to 500°C, depending on material and configuration. Compliant with standards like ASME B16.5 and DIN, these hoses feature corrugated stainless steel cores with optional single or double braiding for added strength. The loose flange, typically carbon steel or stainless steel, is paired with a steel ring or collar to form a reliable sealing surface, preventing contact with corrosive media and ensuring long-term performance in high-pressure hoses.

The corrosion resistance of these hoses makes them suitable for handling aggressive fluids like acids, alkalis, steam, and hydrocarbons, outperforming traditional rigid piping in dynamic systems. The loose flange design allows for axial, lateral, and angular movement, making them perfect for applications requiring vibration damping or compensation for thermal expansion and misalignment. Optional features like PTFE liners or external coatings (e.g., 3LPE) enhance abrasion resistance and durability. These hoses are rigorously tested, including hydrostatic, pneumatic, and fatigue tests, to ensure compliance with industry standards.

Compared to fixed flange metal hoses, flanged loose sleeve metal hoses offer easier installation and maintenance due to the movable flange, reducing stress on the hose and preventing twisting during setup. They are commonly used in pump connectors, HVAC offsets, and chemical transfer lines, where flexibility and ease of maintenance are critical. Custom options, such as larger sizes or specific flange standards (ANSI, JIS, BS), cater to diverse project requirements, ensuring compatibility with complex piping systems.

Flanged loose sleeve metal hoses address challenges like pipeline corrosion, vibration, and installation complexity in industrial systems. Their robust construction, combined with the flexibility of loose flanges, makes them a reliable choice for engineers seeking durable flexible piping solutions for extreme environments, ensuring safety, efficiency, and longevity in applications like refineries, power plants, and water treatment facilities.

Flanged Loose Sleeve Metal Hoses are designed for flexible piping solutions, featuring a unique loose flange design that simplifies installation and maintenance in industrial piping systems. Constructed from high-quality stainless steel (304, 316, or 321), these hoses provide exceptional corrosion resistance and durability, making them ideal for applications in chemical processing, oil and gas, water treatment, and HVAC systems. The loose flange, sleeved over the pipe end, allows for easy alignment and movement without compromising the seal, enhancing vibration damping and flexibility.

Available in sizes from 2” to 14” (DN50 to DN350), flanged loose sleeve metal hoses operate at pressures up to 1500 PSI (10.3 MPa) and temperatures from -200°C to 500°C, depending on material and configuration. Compliant with standards like ASME B16.5 and DIN, these hoses feature corrugated stainless steel cores with optional single or double braiding for added strength. The loose flange, typically carbon steel or stainless steel, is paired with a steel ring or collar to form a reliable sealing surface, preventing contact with corrosive media and ensuring long-term performance in high-pressure hoses.

The corrosion resistance of these hoses makes them suitable for handling aggressive fluids like acids, alkalis, steam, and hydrocarbons, outperforming traditional rigid piping in dynamic systems. The loose flange design allows for axial, lateral, and angular movement, making them perfect for applications requiring vibration damping or compensation for thermal expansion and misalignment. Optional features like PTFE liners or external coatings (e.g., 3LPE) enhance abrasion resistance and durability. These hoses are rigorously tested, including hydrostatic, pneumatic, and fatigue tests, to ensure compliance with industry standards.

Compared to fixed flange metal hoses, flanged loose sleeve metal hoses offer easier installation and maintenance due to the movable flange, reducing stress on the hose and preventing twisting during setup. They are commonly used in pump connectors, HVAC offsets, and chemical transfer lines, where flexibility and ease of maintenance are critical. Custom options, such as larger sizes or specific flange standards (ANSI, JIS, BS), cater to diverse project requirements, ensuring compatibility with complex piping systems.

Flanged loose sleeve metal hoses address challenges like pipeline corrosion, vibration, and installation complexity in industrial systems. Their robust construction, combined with the flexibility of loose flanges, makes them a reliable choice for engineers seeking durable flexible piping solutions for extreme environments, ensuring safety, efficiency, and longevity in applications like refineries, power plants, and water treatment facilities.

| Material | Main Components (%) |

|---|---|

| SS304 | Fe, Cr (18-20%), Ni (8-10.5%), C (≤0.08) |

| SS316 | Fe, Cr (16-18%), Ni (10-14%), Mo (2-3%), C (≤0.08) |

| SS321 | Fe, Cr (17-19%), Ni (9-12%), Ti (≤0.8), C (≤0.08) |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 515-690 (SS304/316/321) |

| Yield Strength (MPa) | 205-275 |

| Pressure Rating (PSI) | Up to 5500 |

| Temperature Range (°C) | -270 to 600 |

| Elongation (%) | 40-50 |

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Flanged loose sleeve metal hose ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Flanged loose sleeve metal hose suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

Delivery

Inner plastic film packing, outer standard export wooden case packing.

Courier company transport, air freight and sea transport. It depends on your actual order details and quantity.

Flanged loose sleeve metal hose are essential in industries requiring flexible, corrosion-resistant solutions for thermal expansion and vibration control in piping systems.

Absorbs thermal expansion in pipelines and refineries.

Handles corrosive media and vibrations.

Protects boilers and turbines from thermal stress.

Ensures leak-free operation in piping systems.

Manages cryogenic temperatures and vibrations.

Reduces noise and vibration in piping.

Flexible metal hoses for drinking water ensure saf...

Flanged loose sleeve metal hoses provide flexible,...

Welded stainless steel metal hoses offer superior ...