Robust Expansion Joints For Stress-free Piping Solutions

Discover high-performance rotary compensators designed to absorb thermal expansion and vibrations in pipelines.

Robust Expansion Joints For Stress-free Piping Solutions

Discover high-performance rotary compensators designed to absorb thermal expansion and vibrations in pipelines. these durable rotary expansion joints ensure stress relief, corrosion resistance, and easy maintenance for industrial piping systems.

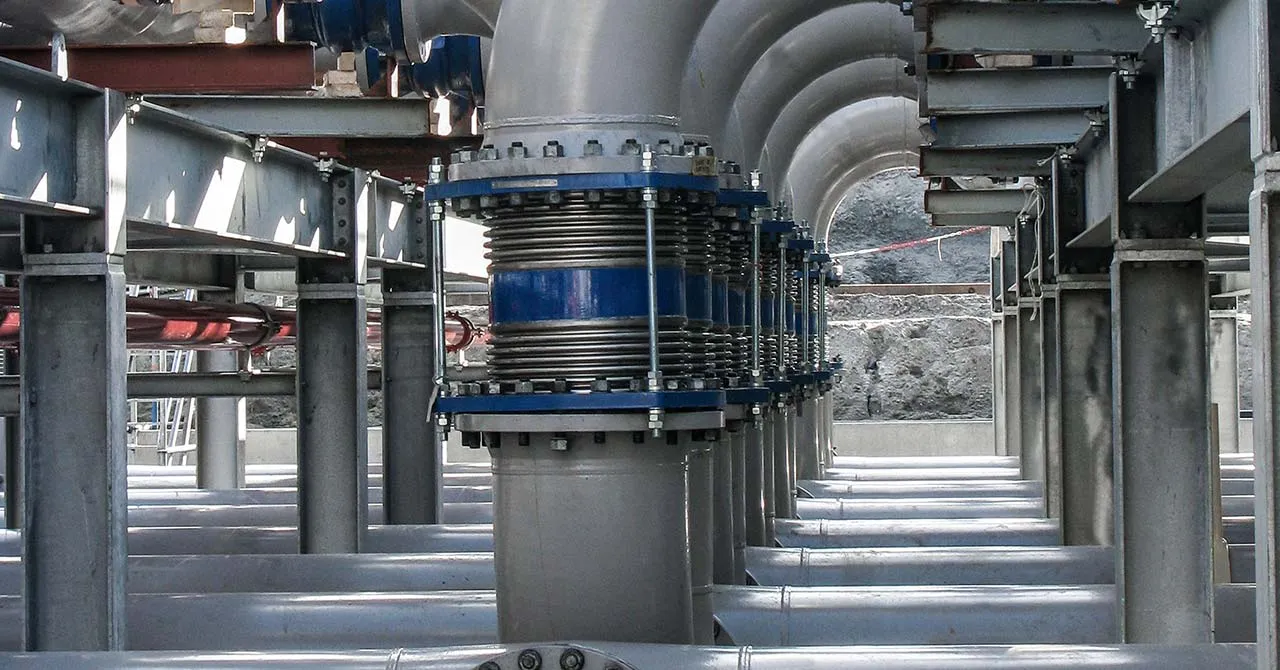

The Rotary Compensator, also referred to as a rotary expansion joint, is a specialized pipe fitting designed to mitigate thermal expansion and mechanical stress in piping systems. Engineered to absorb axial, lateral, and angular movements, this pipeline expansion joint is ideal for industries such as petrochemical, power generation, and oil & gas, where high temperatures and pressures are common. Its core components include a rotating cylinder, sealing gland, antifriction bearings, and flexible sealing materials like graphite, ensuring reliable pipe stress relief under demanding conditions.

Unlike traditional bellows or sleeve compensators, the Rotary Compensator offers enhanced flexibility through its ability to rotate freely along its axis, accommodating complex pipeline movements caused by thermal expansion, vibrations, or ground settlement. Manufactured to standards like GB/T 12777 or EJMA, it is available in sizes from 2" to 48" (DN50 to DN1200), with pressure ratings up to PN25 and operating temperatures exceeding 400°C. Materials such as carbon steel, stainless steel (304/316L), or high-alloy steels provide excellent corrosion resistance, making it suitable for harsh environments handling steam, hot oil, or corrosive gases.

The Rotary Expansion Joint features a low-friction design with antifriction bearings, reducing wear and extending service life up to 20 years. Its sealing system, typically using flexible graphite or PTFE, is compressed by a gland and spring-loaded bolts to maintain a leak-proof seal even under cyclic loads. Rigorous testing, including hydrostatic, torque, fatigue, and non-destructive tests, ensures compliance with industry standards. The compensator requires no pre-tightening during installation, simplifying setup in overhead, buried, or confined piping systems, and reducing thermal expansion absorber costs compared to bellows alternatives.

A key advantage of the Rotary Compensator is its ability to minimize thrust forces on adjacent equipment, preventing pipeline distortion and weld failures. Its rotational design facilitates easy alignment in complex layouts, making it a preferred choice for sleeve compensator applications where space is limited. Optional coatings, such as epoxy or 3LPE, enhance durability in corrosive environments, while custom configurations, like guided or non-thrust designs, cater to specific project needs. This makes it ideal for high-throughput systems requiring reliable pipe movement compensation.

In practical use, the Rotary Compensator excels in applications like steam pipelines in power plants, where it absorbs elongation without requiring extensive pipe loops. Its cost-effective design and ease of maintenance make it a valuable solution for reducing downtime in chemical plants, refineries, and district heating systems. By addressing thermal stress, vibrations, and misalignment, this pipeline expansion joint ensures long-term safety and operational efficiency in demanding industrial settings.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.08 |

| Manganese (Mn) | ≤2.00 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.030 |

| Silicon (Si) | ≤1.00 |

| Chromium (Cr) | 18.0-20.0 |

| Nickel (Ni) | 8.0-12.0 |

| Molybdenum (Mo) | - |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 515 |

| Yield Strength, min (MPa) | 205 |

| Elongation, min (%) | 40 (Longitudinal), 30 (Transverse) |

| Hardness, max (HBW) | 201 |

We are professional in Sleeve compensator include Single flow sleeve compensator, Rotary compensator, Spherical compensator and Non thrust sleeve compensator.

The sleeve type compensator/tube type expansion joint adopts a new type of sealing material flexible graphite ring, which has the characteristics of high strength, no aging, good effect and convenient maintenance. The tubular telescopic joint has a long service life and a fatigue life comparable to that of a pipe.

The sleeve compensator, also known as a pipe-type expansion joint, functions as a compensating device within hot fluid pipelines. Its primary application is in the auxiliary equipment of straight pipelines. It is suitable for conveying hot water, steam, grease, and other media. It achieves thermal expansion compensation through the sliding movement of the inner sleeve relative to the outer sleeve.

The sleeve compensator is designed for use in medium engineering applications with a pressure rating of ≤2.5MPa and is suitable for a temperature range of -40℃ to 600℃.

This compensator employs a new type of sealing material, namely, a flexible graphite ring. This material offers several advantages, including high strength, a low friction coefficient (0.04~0.10), resistance to aging, and effective sealing, along with easy maintenance.

The sleeve compensator boasts a lengthy service life, with fatigue resistance equivalent to that of the pipeline. Its sliding surface is specially treated to provide excellent corrosion resistance, even in saltwater, salt solutions, and similar environments, surpassing austenitic stainless steel by over 50 times. In cases where the sealing effect weakens due to wear over many years, the flange can be retightened to enhance the sealing performance. Alternatively, the bolts can be loosened, the pressure ring can be removed, and one or two layers of sealing rings can be added to compress the pressure ring for continued use.

Specify the correct diameter and length to fit your piping system.

Consider the full operating temperature range for durability and safety.

Match the expansion joint to the type of system and operating conditions.

Identify the media and pressure range for safe, leak-free operation.

Delivery

Inner plastic film packing, outer standard export wooden case packing.

Courier company transport, air freight and sea transport. It depends on your actual order details and quantity.

Rotary Compensator are essential in industries requiring flexible, corrosion-resistant solutions for thermal expansion and vibration control in piping systems.

Absorbs thermal expansion in pipelines and refineries.

Handles corrosive media and vibrations.

Protects boilers and turbines from thermal stress.

Ensures leak-free operation in piping systems.

Manages cryogenic temperatures and vibrations.

Reduces noise and vibration in piping.

A spherical compensator, also known as a spherical...

Explore single flow sleeve compensators designed t...

A non-thrust sleeve compensator is a type of expan...