U bend tube

Precision Heat Exchanger Components

U bend tubes are meticulously crafted for heat exchangers in high-temperature applications, especially steam condensing or hot oil systems, ensuring efficient heat transfer and structural integrity.

Precision Heat Exchanger Components

U bend tubes are meticulously crafted for heat exchangers in high-temperature applications, especially steam condensing or hot oil systems, ensuring efficient heat transfer and structural integrity.

The U-Bend Pipe Compensator, also known as a pipeline expansion joint, is a specially designed component that absorbs thermal expansion and contractions in piping systems, ensuring pipe stress relief. Engineered for industries such as petrochemical, power generation, district heating, and water supply, this axial compensator utilizes a U-shaped configuration to accommodate axial and lateral movements caused by temperature changes, vibrations, or ground settlement. Its robust construction, typically made from carbon steel or stainless steel, ensures excellent corrosion resistance and durability in harsh environments.

The U-Bend Pipe Compensator operates by leveraging the natural flexibility of its U-shaped geometry to absorb thermal elongation and contraction, reducing stress on pipeline components. Conforming to standards like GB/T 12777 or industry-specific guidelines, it is available in sizes ranging from 2" to 48" (DN50 to DN1200), with pressure ratings up to PN16 and operating temperatures up to 400°C. Materials such as carbon steel, stainless steel (304/316L), or alloy steels, combined with optional coatings like 3LPE or epoxy, provide superior resistance to corrosion and wear, making it suitable for steam, hot water, or corrosive fluid pipelines.

Unlike bellows-type or sleeve compensators, the U-Bend Pipe Compensator is a simple, cost-effective solution that requires minimal maintenance and no specialized sealing components. Its design allows for self-compensation, eliminating the need for additional anchors in many applications, which reduces installation costs. Rigorous testing, including hydrostatic, bending stress, and fatigue tests, ensures compliance with industry standards. The U-bend’s flexibility makes it ideal for long, straight pipeline sections where thermal expansion is significant, acting as an efficient thermal expansion absorber.

The U-Bend Pipe Compensator is particularly effective in applications requiring large axial compensation, such as district heating or oil and gas pipelines. Its ability to handle thermal elongation without imposing significant thrust forces makes it a preferred choice for systems with limited anchor points. The compensator’s seamless or welded construction ensures compatibility with various piping configurations, and its design allows for easy integration into existing systems, enhancing pipe movement compensation in challenging environments.

In practical applications, the U-Bend Pipe Compensator minimizes pipeline stress in power plants, chemical refineries, and municipal water systems, preventing cracks, leaks, and costly downtime. Its simplicity, long service life, and low maintenance requirements make it an economical and reliable solution for engineers seeking effective pipeline expansion joint solutions for high-temperature and high-pressure systems.

| Tube OD | Tube thickness | Bending Radius | Straight “leg” length | Straight tube before U bending |

|---|---|---|---|---|

| Min. 12.7 mm / Max. 31.75 mm | Min. 0.70 mm / Max. 4.19 mm | Min. 1.5 x OD / Max. 1250 mm | Max. 12500 mm | Max. 27000 mm |

The dimensional checks are performed using calibrated measuring instruments and gauges to ensure the U-bend tubes meet the specified tolerances and quality standards. Proper documentation of the inspection results is maintained for traceability and quality assurance purposes.

The semi-finished product for U bend tubes are heat exchanger tubes, manufactured and supplied according to DIN 28180 and ASTM A179.

| Standard | Application |

|---|---|

| ASTM A179 | Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

| ASTM A192 | Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

| ASTM A210 | Seamless Medium-Carbon Steel Boiler and Superheater Tubes |

| ASTM A213 | Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

| ASTM A334 | Seamless Steel Pipe for Low-Temperature Service and other Applications with Required Notch Toughness |

| JIS G3461/2 | Carbon steel tubes used for heat exchange in boilers, heat exchangers, condensers, and similar equipment |

| EN10216-1/2 | Specified the standard of cold processed precision steel tubes in a wide range of sizes |

| DIN17175 | Seamless tubes for high-pressure and high-temperature applications, specifically for boilers and heat exchangers |

| Standard | Grade | Chemical Components (%) | Mechanical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Mo | Cr | V | T.S. (Mpa) | Y.S. (Mpa) | E.L. (%) | Hardness (HRB) | ||

| ASME SA179 | SA179 | 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / | ≥325 | ≥180 | ≥35 | ≤72 |

| ASME SA192 | SA192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / | ≥325 | ≥180 | ≥35 | ≤77 |

| ASME SA210 | A1 | ≤0.27 | ≥0.10 | ≤0.93 | ≤0.035 | ≤0.035 | / | / | / | ≥415 | ≥255 | ≥30 | ≤79 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | / | / | / | ≥485 | ≥275 | ≥30 | ≤89 | |

| ASTM A333 /A334 | GR.1 | ≤0.30 | / | 0.4-1.06 | ≤0.025 | ≤0.025 | / | / | / | ≥380 | ≥205 | ≥35 | -45° |

| GR.6 | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.025 | ≤0.025 | / | / | / | ≥415 | ≥240 | ≥30 | -45° | |

| GR.8 | ≤0.13 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | / | / | 8.40-9.60 | ≥690 | ≥515 | ≥22 | -195° | |

U bend tubes for heat exchangers applied mostly in oil and gas plants, chemical and petrochemical plants, refineries, power plants and renewable energy plants. Low fin tubes can be supplied in the form of U bends.

U-bend tubes are widely used in heat-exchanger systems. Heat-exchanger equipment on the basis of seamless stainless U-tubes is essential in strategically important and critical fields — nuclear and petrochemical machine building.

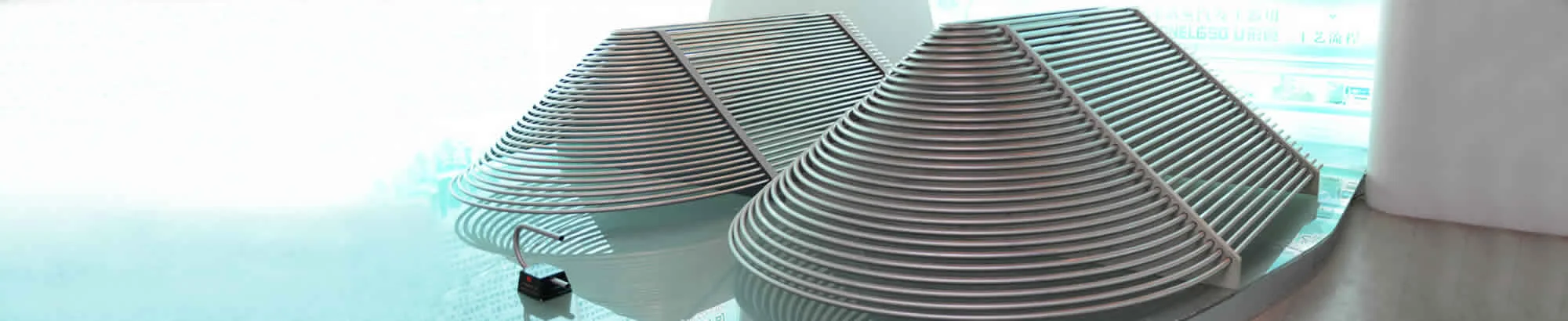

a...................The difference in length between two straight pipe

sections

c..............The tangent spacing of the outer wall of the elbow

Da............nominal steel pipe outer diameter

E..............The distance between the outer diameters of the two straight

ends

f...............the distance between the ends of the two straight ends

l............... straight tube length

Lg............. straight pipe section plus total length of pipe

Rm...........nominal bending radius

S.............nominal wall thickness

Smin.......The minimum wall thickness at the back of the elbow

t...............the bend deviates from the horizontal distance

So...........Standard minimum wall thickness

| Item | Condition (when) | Tolerance |

|---|---|---|

| Ovality | Nominal bend radius ≤ 2 x nominal OD | less than or equal to 12% |

| 2 x nominal OD < Nominal bend radius ≤ 4 x nominal OD | less than or equal to 10% | |

| Nominal bend radius > 4 x nominal OD | less than or equal to 5% | |

| Nominal bend radius ≤ 2 x nominal OD | 0.75 x nominal wall | |

| Minimum wall thickness | 2 x nominal OD < Nominal bend radius ≤ 4 x nominal OD | 0.8 x nominal wall |

| Nominal bend radius > 4 x nominal OD | 0.9 x nominal wall | |

| Nominal bend radius ≤ 8" (200mm) | +/-3/64"(1mm) | |

| Bending Radius | 8" (200mm) < Nominal bend radius ≤ 16" (400mm) | +/-1/16"(1mm) |

| Nominal bend radius >16" (400mm) | +/-5/64"(1mm) | |

| Distance between legs | - | Max 1/16"(1.5mm) |

| Wall thinning of bending area | - | Max 17% |

| Difference between leg lengths at the ends | Leg length ≤ 16' (4.88m) | +1/8"(3mm) |

| Leg length > 16' (4.88m) | +3/16"(5mm) | |

| Deviation from plane of bend | - | ≤ 3/16"(1.5mm) |

| Flattening on bend | - | ≤ 10% nominal diameter |

| Straight leg length | ≤5m | +1/8"(3mm) |

| >5m | +3/16"(5mm) | |

| Total tube length including radius | ≤6m | +3/16"(5mm) |

| >6m | +5/16"(8mm) |

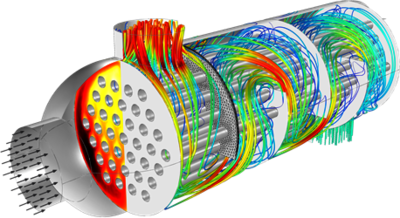

U-Tube heat exchangers are known for their distinctive U-shaped tubes that offer several advantages and also come with certain limitations.

The U-tube heat exchanger features a single tubesheet with both ends of the tubes secured to it. This design allows the tubes to expand and contract freely, avoiding thermal stress and offering excellent thermal compensation. A double tube pass is utilized, providing a lengthy process path, high flow rates, and superior heat transfer performance with robust pressure resistance. The tube bundle is removable from the shell for convenient maintenance and cleaning, presenting a simple structure and low cost.

Limitations imposed by the elbow's curvature radius restrict the arrangement of heat exchange tubes. This results in a larger inner tube spacing within the tube bundle and a lower utilization rate of the tube sheet. The shell-side fluid is prone to short-circuiting, which can impede heat transfer. When a tube leaks or sustains damage, only the U-shaped tubes on the outer part of the bundle can be readily replaced. Damage to the inner heat exchange tubes is not as easily repairable and may require blocking off. Furthermore, the damage to a single U-shaped tube equates to the loss of two tubes, leading to a higher scrap rate.

U-bend tubes are used to transfer heat between fluids.

Transfers heat between fluids, allowing return flow at 180° in a compact space.

Used in heat exchangers, chemical & petrochemical, food processing, and refrigeration industries.

Applied in heat exchangers at Oil & Gas, petrochemical plants, refineries, and power plants.

Handles aggressive fluids like sodium hydroxide + sodium hypochlorite safely.

Allows pipeline expansion without buckling; flexible or sliding options available.

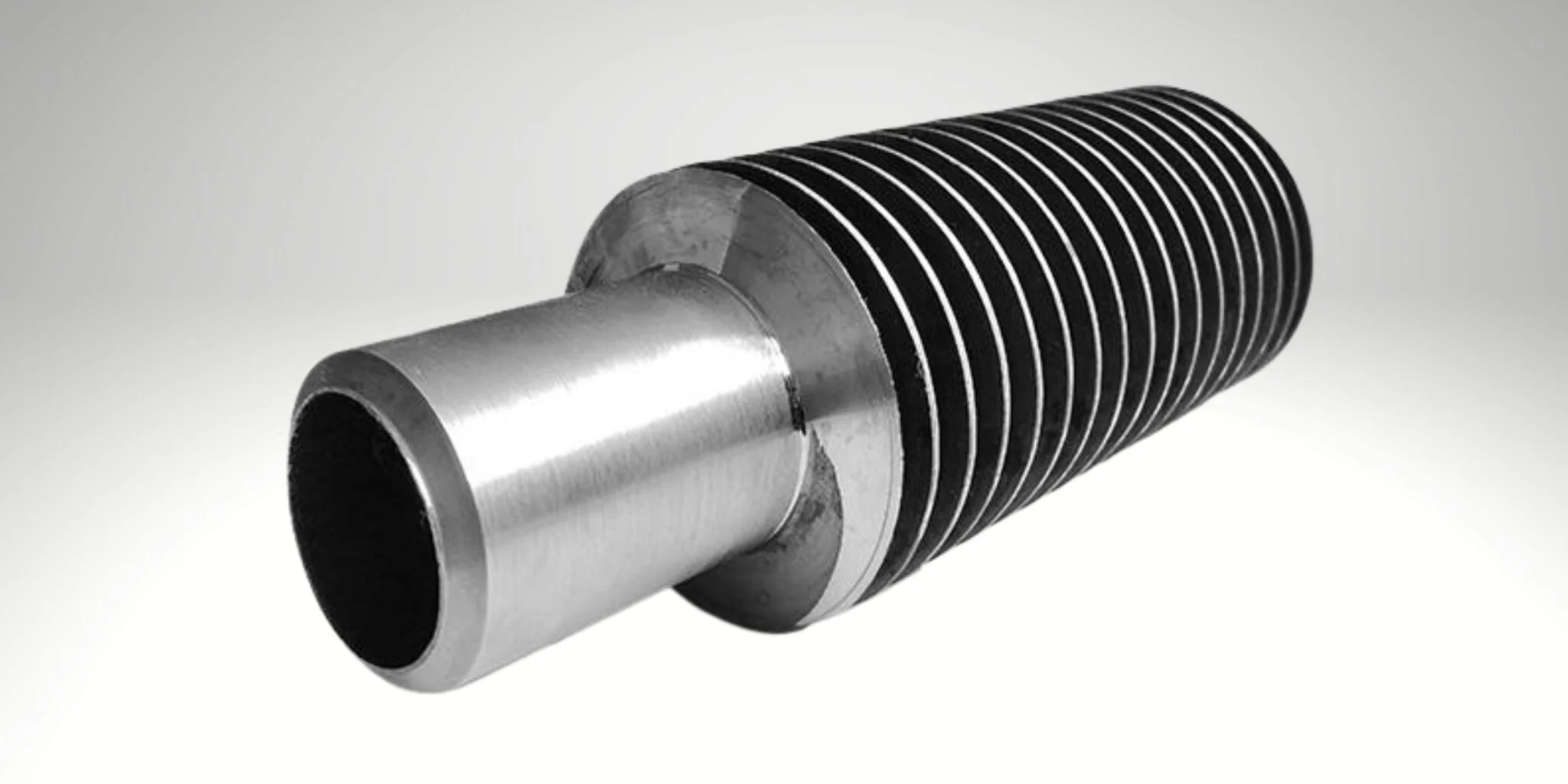

Enhances heat transfer when the outside coefficient is lower than the inside, improving efficiency.

Pipe flanges are basically plates or rings used to...

A buttweld pipe fitting is a weldable component us...

Weldolets provide strong, corrosion-resistant bran...

Fin tubes are specialized heat exchanger component...

Industrial valves are critical devices used to con...

Pipe couplings are essential fittings for connecti...