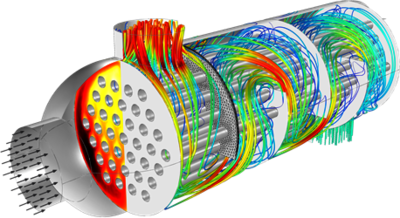

ASTM A192 U-Bend Tubes are seamless carbon steel tubes engineered for high-pressure service in boiler tubes and heat exchanger tubes. Conforming to ASTM A192/ASME SA192 specifications, these U-shaped tubing solutions are ideal for applications in power generation, petrochemical, and industrial plants, where corrosion resistance and pipeline durability are critical. The U-bend design enhances heat transfer efficiency and acts as a thermal expansion absorber, reducing stress in high-temperature systems.

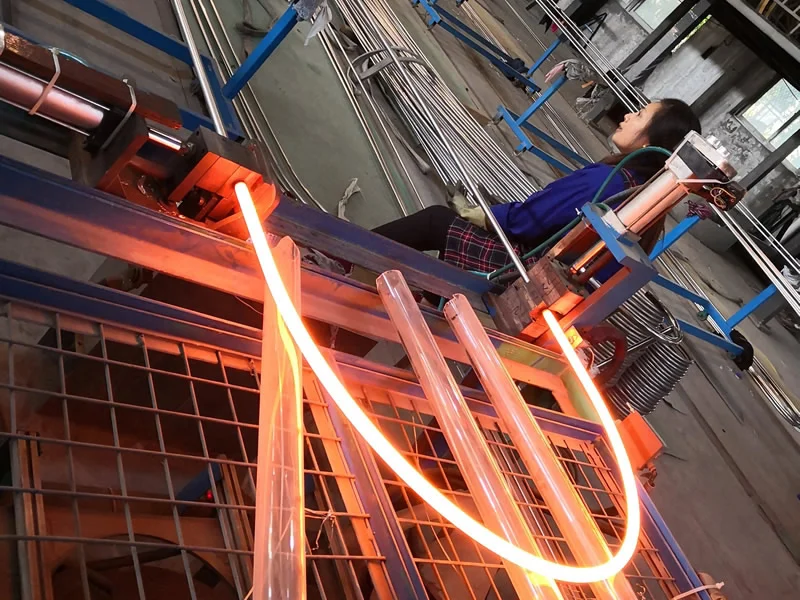

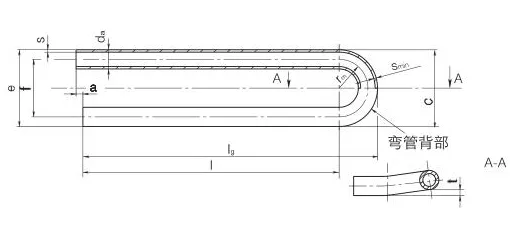

Manufactured through a seamless, cold-drawn process, ASTM A192 U-Bend Tubes feature a minimum wall thickness ranging from 1.65mm to 2.77mm and outer diameters from 12.7mm to 38.1mm. The tubes can be customized with bend radii from 1.5 times the outer diameter to 1250mm and leg lengths up to 26 meters, catering to specific project requirements. Post-bending heat treatment at a minimum of 650°C ensures optimal mechanical properties, while protective argon gas filling during heat treatment prevents oxidation. Surface treatments like varnishing or pickling further enhance corrosion resistance.

These boiler tubes undergo stringent testing, including hydrostatic, flattening, flaring, and hardness tests, to comply with ASTM A450/A450M standards. With a minimum tensile strength of 325 MPa and yield strength of 180 MPa, they are designed to withstand pressures up to 9.8 MPa and temperatures between 450°C and 650°C. The U-bend configuration minimizes thermal stress and eliminates the need for expansion joints, making them space-efficient and cost-effective for heat exchanger tubes in compact designs.

The ASTM A192 U-Bend Tubes are particularly suited for high-pressure boilers, superheaters, economizers, and reheaters, offering reliable performance in harsh environments like coal, thermal, and oil power plants. Their carbon steel composition (0.06-0.18% carbon, 0.27-0.63% manganese) ensures good weldability and formability, allowing for bending and flanging without cracking. Compared to ASTM A179 tubes, A192 tubes are optimized for higher-pressure applications, while their seamless construction ensures leak-free performance.

Addressing challenges like pipeline wear, corrosion, and thermal stress, ASTM A192 U-Bend Tubes provide a robust solution for engineers seeking durable and efficient boiler tubes. Their high thermal conductivity and long service life make them a preferred choice for critical applications in demanding industrial settings.