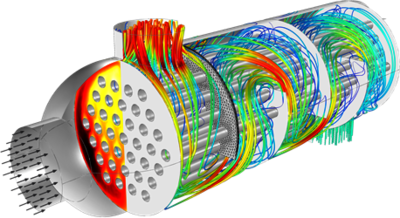

ASTM A179 U-Bend Tubes are seamless, cold-drawn low-carbon steel tubes designed for

heat exchanger tubes and condensers, offering superior corrosion resistance and

thermal conductivity. Conforming to ASTM A179/ASME SA179 specifications, these U-shaped tubing

solutions are widely used in industries such as petrochemical, power generation, chemical processing, and food and

beverage, where pipeline durability and efficient heat transfer are essential. The U-bend design

acts as a thermal expansion absorber, reducing stress in compact heat exchanger systems.

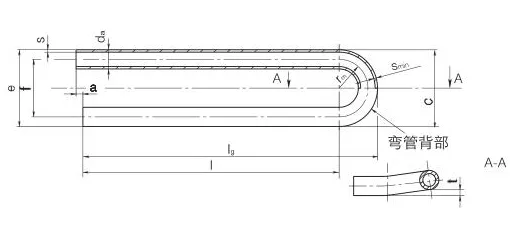

Manufactured through a cold-drawing process, ASTM A179 U-Bend Tubes are produced with outer

diameters ranging from 12.7mm to 38.1mm, wall thicknesses from 1.65mm to 2.77mm, and bend radii from 1.5 times the

outer diameter to 1250mm. Leg lengths can be customized up to 26 meters, meeting diverse project requirements.

Post-bending heat treatment at 1200°F (650°C) or higher ensures stress relief and optimal mechanical properties,

while surface treatments like varnishing, pickling, or galvanization enhance corrosion resistance.

The tubes are packed in wooden boxes or bundles with plastic caps to prevent contamination during transport.

These boiler tubes undergo rigorous testing, including hydrostatic, flaring, flattening, and

hardness tests, to comply with ASTM A450/A450M standards. With a minimum tensile strength of 325 MPa, yield strength

of 180 MPa, and elongation of 35%, they are designed for efficient heat transfer in low-to-medium temperature

applications (up to 450°C). The low-carbon steel composition (0.06-0.18% carbon, 0.27-0.63% manganese) ensures

excellent weldability and formability, making them suitable for bending and flanging without cracking.

Compared to ASTM A192 tubes, ASTM A179 U-Bend Tubes are optimized for lower-pressure,

lower-temperature applications, making them ideal for tubular heat exchangers and condensers. Their seamless

construction minimizes the risk of leaks, ensuring reliable performance in corrosive environments, such as those

involving water or chemical fluids. The U-bend design eliminates the need for additional fittings or expansion

joints, reducing installation costs and space requirements in heat exchanger systems.

The ASTM A179 U-Bend Tubes address critical challenges like pipeline wear, corrosion, and thermal

stress in industrial systems. Their high thermal conductivity, durability, and ease of maintenance make them a

preferred choice for engineers seeking reliable heat exchanger tubes for applications requiring

consistent performance and longevity in demanding environments.

Bending Process of ASTM A179 Tubes

Precision tube bending ensures ASTM A179 tubes maintain their structural integrity and performance

in heat exchanger and boiler applications.

Step-by-Step Procedure

- Prepare the equipment: Set up a calibrated tube bending machine.

- Select the bending tool: Match tool to bend radius, angle, diameter, and wall thickness.

- Mark the bending points: Use scribe or marker for accurate alignment.

- Secure the tube: Properly align and clamp the tube in the machine.

- Bend the tube: Gradually bend to the desired angle and radius using controlled force.

- Inspect the bend: Check for smooth finish without cracks or deformation.

Key Considerations

- Use specialized bending machines designed for heat exchanger tubes.

- Ensure correct bend radius to avoid tube ovalization and thinning.

- Maintain tube wall thickness and dimensional tolerances.

- Conduct visual and dimensional checks after bending.

- Apply non-destructive testing (if required) for critical applications.

Ensuring Reliability

Proper bending techniques and quality inspections ensure ASTM A179 tubes

deliver consistent performance in high-pressure and high-temperature environments.

FAQs

Engineered to meet diverse industrial needs with robust materials and versatile designs.

ASTM A179 U-Bend Tubes are seamless, cold-drawn low-carbon

steel tubes bent into a U-shape, used in heat exchangers and condensers for efficient heat transfer.

They are used in heat exchangers, condensers, and similar heat transfer

equipment in petrochemical, power generation, chemical, and food processing industries.

Made from low-carbon steel with 0.06-0.18% carbon and 0.27-0.63% manganese,

with optional coatings like varnishing or galvanization for enhanced corrosion resistance.

For ASTM A179: - Carbon (C): 0.06-0.18% - Manganese (Mn): 0.27-0.63% -

Phosphorus (P): ≤0.035% - Sulfur (S): ≤0.035% - Silicon (Si): ≤0.25%

For ASTM A179: - Tensile Strength: ≥325 MPa - Yield Strength: ≥180 MPa -

Elongation: ≥35% - Hardness: ≤72 HRB

Outer diameters range from 12.7mm to 38.1mm, wall thicknesses from 1.65mm

to 2.77mm, with bend radii of 1.5D to 1250mm. Tolerances comply with ASTM A450/A450M.

Produced via seamless cold-drawing, followed by mandrel bending and heat

treatment at ≥650°C to enhance mechanical properties and corrosion resistance.

Tests include hydrostatic, flaring, flattening, hardness, and dimensional

inspections to ensure compliance with ASTM A179/A450 standards.

Installed in heat exchanger tube sheets with welded or expanded ends, with

capped ends to prevent contamination during transport and setup.

ASTM A179 tubes are suited for lower-temperature, lower-pressure heat

exchangers, while A192 tubes are designed for higher-pressure boiler applications (up to 9.8 MPa).