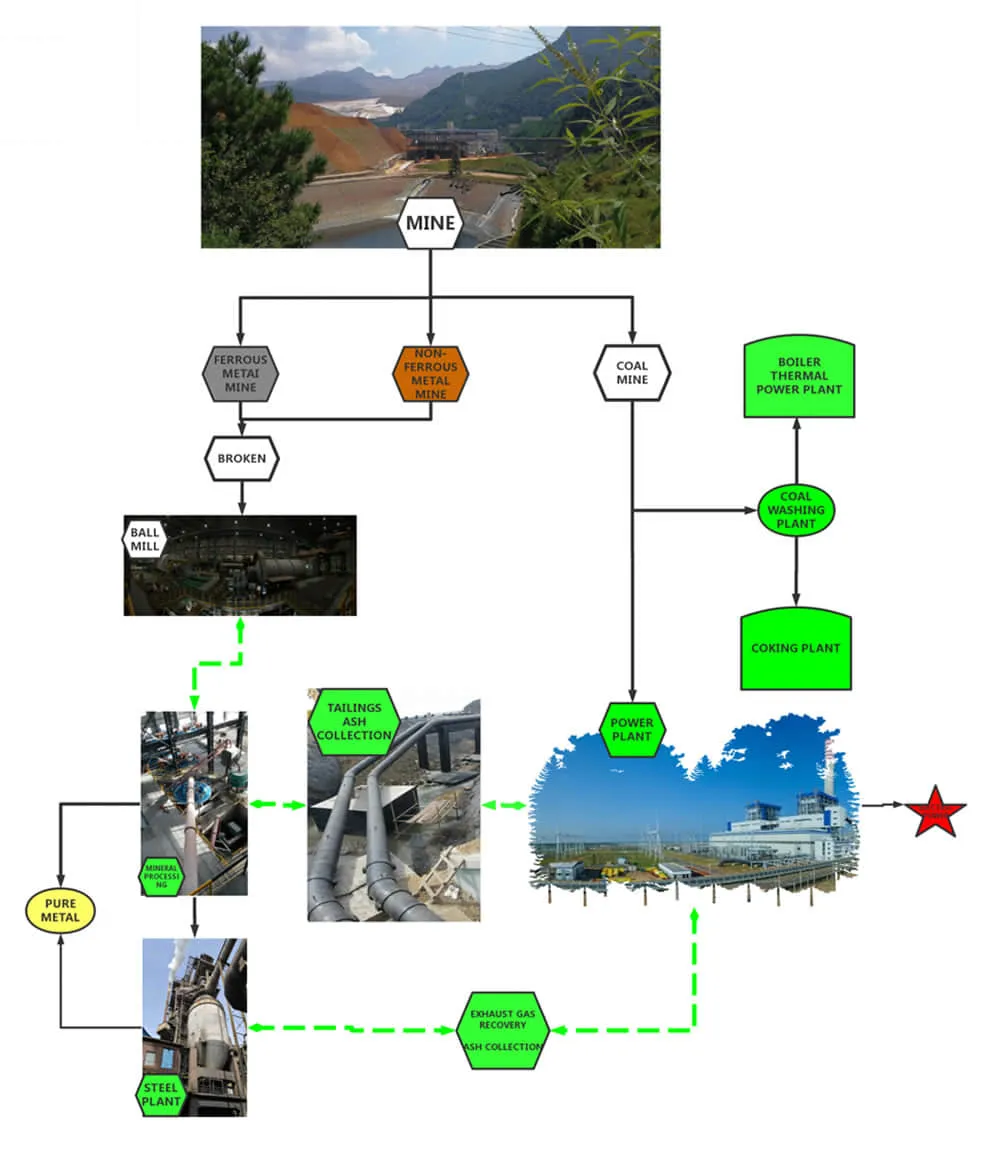

Cast Basalt Composite Elbows are engineered for exceptional durability in demanding industrial environments, where abrasive, chemical, and high-temperature materials are transported. These elbows are composed of a steel pipe outer shell, lined with cast basalt—a volcanic rock material known for its superior hardness and abrasion resistance—and filled with cement mortar to enhance structural integrity. The cast basalt lining, with a Mohs hardness of 8, provides outstanding protection against sliding abrasion, making it an ideal choice for industries such as mining, power generation, cement production, chemical processing, and coal handling.

The unique properties of Cast Basalt Composite Elbows include excellent corrosion resistance to most acids and alkalis (except hydrofluoric acid), ensuring long-term performance in harsh chemical environments. These elbows can withstand temperatures up to 450°C, making them suitable for high-temperature applications. The basalt lining polishes over time as materials pass through, reducing friction and improving flow efficiency, which enhances operational performance. The external steel shell provides robust impact strength, surpassing that of traditional Ni-hard pipes, while the cement mortar filling creates an alkali medium inside the pipe, generating a protective film to prevent rusting.

Available in standard sizes ranging from 50NB to 500NB, Cast Basalt Composite Elbows can also be customized to meet specific requirements, including non-standard specifications and larger diameters exceeding 800mm. The bend radius is designed to be at least three times the nominal bore, and a straight pipe section of 5 to 12 times the nominal bore is recommended at the discharge end to optimize performance. Connection methods, such as flange or welding, ensure secure integration into existing pipeline systems, maintaining airtightness and reliability.

Compared to traditional materials like cast iron or Ni-hard steel, basalt-lined elbows offer a lifespan 7 to 10 times longer than cast iron and 3 to 4 times longer than Ni-hard steel, significantly reducing maintenance costs and downtime. Their versatility makes them suitable for conveying abrasive media like slurry, ash, ore, and granular materials, providing a cost-effective solution for wear-resistant piping needs. Whether used in straight pipes, tees, reducers, or elbows, these composite fittings deliver unmatched durability and performance, making them a preferred choice for industrial pipeline systems worldwide.