Low Alloy U-Bent Tubes are seamless or welded tubes crafted from low alloy steel, bent

into a U-shape for use in heat exchanger tubes and boiler tubes. Conforming to

standards like ASTM A213 (T5, T9, T11, T22, T91) and JIS G3462, these tubes are engineered for high-pressure and

high-temperature applications in industries such as petrochemical, power generation, oil and gas, and chemical

processing. Their corrosion resistance and ability to act as a thermal expansion

absorber make them ideal for enhancing pipeline durability in demanding environments.

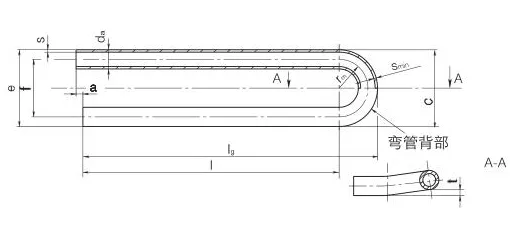

Manufactured using cold-drawing or hot-rolling processes, Low Alloy U-Bent Tubes feature outer

diameters from 6.35mm to 50.8mm, wall thicknesses from 0.8mm to 6mm, and bend radii from 1.5D to 1500mm,

customizable to client specifications. Post-bending heat treatment, such as stress relief annealing at 650-720°C or

normalizing at 850-950°C, ensures optimal mechanical properties and prevents cracking. Surface treatments like

pickling, passivation, or 3LPE coating enhance corrosion resistance, while plastic caps protect

tube ends during transport.

These tubes undergo rigorous testing, including hydrostatic, eddy current, flaring, flattening, and hardness tests,

to meet ASTM A450/A450M and TEMA standards. With tensile strengths ranging from 415 MPa (T11) to 620 MPa (T91) and

yield strengths from 205 MPa to 440 MPa, they are designed for temperatures up to 650°C and pressures up to 10 MPa.

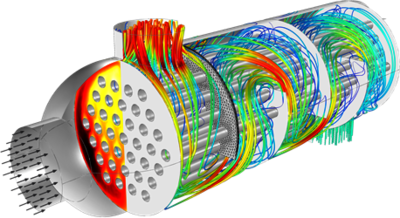

The U-bend design minimizes thermal stress, eliminates the need for expansion joints, and reduces installation

costs, making them ideal for compact heat exchanger systems.

The low alloy steel composition, typically containing 1-5% chromium (Cr) and 0.5-1% molybdenum (Mo), provides

superior corrosion resistance and creep strength compared to carbon steel, while being more

cost-effective than stainless steel. Common grades like T11 and T22 are suited for boiler superheaters, while T91 is

used in high-temperature, high-pressure applications like power plant reheaters. The seamless construction ensures

leak-free performance, and their ability to handle abrasive fluids makes them suitable for pneumatic conveying

systems.

Addressing challenges like pipeline wear, corrosion, and thermal stress, Low Alloy U-Bent Tubes

offer a robust solution for engineers seeking reliable heat exchanger tubes. Their high

strength-to-weight ratio, durability, and low maintenance requirements make them a preferred choice for critical

applications in harsh industrial environments, ensuring long-term performance and efficiency.

Low Alloy U-Bent Tubes

Engineered for heat exchanger efficiency, low alloy U-bent tubes combine strength, heat resistance,

and cost-effectiveness for industrial applications.

Materials

High & low yield stainless steels

Alloy steels with Cr, Mo, Ni

Carbon steels for cost efficiency

Selection Factors

Mechanical strength

Corrosion resistance

Heat resistance

Purpose of U-Bend

Simplifies fluid routing in piping systems, reducing the need for additional fittings

while enhancing installation flexibility.

Heat Exchangers

Designed for high-pressure, high-temperature service in boilers and condensers.

Chemical & Petrochemical

Withstands aggressive media in refineries and process plants.

Food & Refrigeration

Efficient heat transfer in refrigeration and food processing equipment.

Oil & Gas

Reliable for offshore, refinery, and gas plant heat exchanger units.

Performance Assurance

Low alloy U-bent tubes deliver long service life with excellent heat transfer,

high mechanical strength, and adaptability for critical industries.

Chemical Composition of Low Alloy U-Bent Tubes (ASTM A213 T11)

| Element |

Composition (%) |

| Carbon (C) |

0.05-0.15 |

| Manganese (Mn) |

0.30-0.60 |

| Phosphorus (P) |

≤0.025 |

| Sulfur (S) |

≤0.025 |

| Silicon (Si) |

0.50-1.00 |

| Chromium (Cr) |

1.00-1.50 |

| Molybdenum (Mo) |

0.44-0.65 |

Mechanical Properties of Low Alloy U-Bent Tubes (ASTM A213 T11)

| Property |

Value |

| Tensile Strength, min (MPa) |

415 |

| Yield Strength, min (MPa) |

205 |

| Elongation, min (%) |

30 |

| Hardness, max (HBW) |

163 |

Chemical Composition of Low Alloy U-Bent Tubes (ASTM A213 T91)

| Element |

Composition (%) |

| Carbon (C) |

0.08-0.12 |

| Manganese (Mn) |

0.30-0.60 |

| Phosphorus (P) |

≤0.020 |

| Sulfur (S) |

≤0.010 |

| Silicon (Si) |

0.20-0.50 |

| Chromium (Cr) |

8.00-9.50 |

| Molybdenum (Mo) |

0.85-1.05 |

| Vanadium (V) |

0.18-0.25 |

| Niobium (Nb) |

0.06-0.10 |

Mechanical Properties of Low Alloy U-Bent Tubes (ASTM A213 T91)

| Property |

Value |

| Tensile Strength, min (MPa) |

620 |

| Yield Strength, min (MPa) |

440 |

| Elongation, min (%) |

20 |

| Hardness, max (HBW) |

250 |

FAQs

Engineered to meet diverse industrial needs with robust materials and versatile designs.

Low Alloy U-Bent Tubes are seamless or welded tubes made

from low alloy steel, bent into a U-shape for heat exchangers and boilers, offering high strength

and corrosion resistance.

They are used in heat exchangers, boilers, superheaters, and condensers in

petrochemical, power generation, oil and gas, and chemical industries.

Made from low alloy steel (e.g., ASTM A213 T11, T91) with 1-5% chromium and

0.5-1% molybdenum, often with coatings like 3LPE or passivation for enhanced corrosion resistance.

For ASTM A213 T11:

- Carbon (C): 0.05-0.15%

- Manganese (Mn):

0.30-0.60%

- Phosphorus (P): ≤0.025%

- Sulfur (S): ≤0.025%

- Silicon (Si):

0.50-1.00%

- Chromium (Cr): 1.00-1.50%

- Molybdenum (Mo): 0.44-0.65%

For ASTM A213

T91:

- Carbon (C): 0.08-0.12%

- Manganese (Mn): 0.30-0.60%

- Phosphorus (P): ≤0.020%

- Sulfur (S): ≤0.010%

- Silicon (Si): 0.20-0.50%

- Chromium (Cr): 8.00-9.50%

-

Molybdenum (Mo): 0.85-1.05%

- Vanadium (V): 0.18-0.25%

- Niobium (Nb): 0.06-0.10%

For ASTM A213 T11:

- Tensile Strength: ≥415 MPa

- Yield Strength:

≥205 MPa

- Elongation: ≥30%

- Hardness: ≤163 HBW

For ASTM A213 T91:

- Tensile

Strength: ≥620 MPa

- Yield Strength: ≥440 MPa

- Elongation: ≥20%

- Hardness: ≤250 HBW

Outer diameters range from 6.35mm to 50.8mm, wall thicknesses from 0.8mm to

6mm, with bend radii of 1.5D to 1500mm. Tolerances comply with ASTM A450/A450M and TEMA standards.

Produced via cold-drawing or hot-rolling, followed by mandrel bending and

heat treatment (stress relief at 650-720°C or normalizing at 850-950°C) to enhance properties.

Tests include hydrostatic, eddy current, flaring, flattening, and hardness

tests to ensure compliance with ASTM A450/A450M and TEMA standards.

Installed in heat exchanger or boiler tube sheets with welded or expanded

ends, with capped ends to prevent contamination during transport.

Low alloy U-bent tubes offer higher strength and creep resistance at a

lower cost than stainless steel, but have less corrosion resistance in highly corrosive

environments.