U-Shaped Heat Exchanger Tubes are seamless or welded tubes bent into a U-shape,

designed to optimize heat transfer in heat exchanger tubes and boiler tubes.

Conforming to standards like ASTM A179, A192, A213, and JIS G3462, these tubes are essential for industries such as

petrochemical, power generation, chemical processing, and HVAC systems. Their corrosion resistance

and function as a thermal expansion absorber enhance pipeline durability in

high-temperature and high-pressure environments.

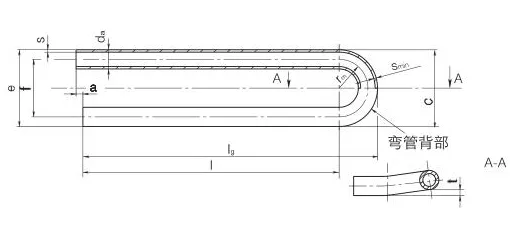

Manufactured through cold-drawing or hot-rolling processes, U-Shaped Heat Exchanger Tubes feature

outer diameters from 6.35mm to 50.8mm, wall thicknesses from 0.8mm to 6mm, and bend radii from 1.5D to 1500mm,

customizable to project requirements. Post-bending heat treatments, such as stress relief annealing (650-720°C for

carbon and alloy steel) or solution annealing (1010-1193°C for stainless steel), ensure optimal mechanical

properties and prevent cracking. Surface treatments like pickling, passivation, or 3LPE coating improve

corrosion resistance, while capped ends protect tubes during transport.

These tubes undergo rigorous testing, including hydrostatic, eddy current, flaring, flattening, and hardness tests,

to comply with ASTM A450/A450M and TEMA standards. With tensile strengths ranging from 325 MPa (carbon steel) to 620

MPa (alloy steel) and yield strengths from 180 MPa to 440 MPa, they are designed for temperatures up to 650°C and

pressures up to 10 MPa. The U-shaped design minimizes thermal stress, eliminates the need for expansion joints, and

reduces installation costs, making them ideal for compact heat exchanger systems.

Available in materials like carbon steel (ASTM A179, A192), low-alloy steel (ASTM A213 T11, T91), and stainless

steel (304, 316), U-Shaped Heat Exchanger Tubes offer versatility for various applications. Carbon

steel tubes excel in low-to-medium temperature systems, while alloy and stainless steel grades provide superior

corrosion resistance and creep strength for high-temperature environments. The seamless

construction ensures leak-free performance, and their ability to handle corrosive fluids makes them suitable for

chemical processing and pneumatic conveying systems.

Addressing challenges like pipeline wear, corrosion, and thermal stress, U-Shaped Heat Exchanger

Tubes provide a reliable solution for engineers seeking efficient boiler tubes and

heat exchanger tubes. Their high thermal conductivity, durability, and low maintenance requirements

make them a preferred choice for critical applications in demanding industrial settings, ensuring long-term

performance and efficiency.

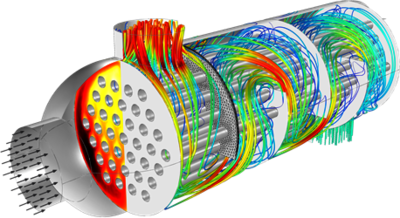

The bend side is free-floating and this helps in thermal expansion without requiring expansion joints. U-tube heat exchangers have a simple structure which makes them easy to manufacture and maintain. They are commonly used in shell and U-tube heat exchangers.

U bent heat exchanger tubes are used in various industrial applications for heat transfer between fluids, such as in boilers and condensers. U bent heat exchanger tubes are made from a variety of materials including stainless steel, titanium, and copper alloys depending on the application and environmental factors. They are typically designed to withstand high temperatures and pressures and are used in both liquid and gas applications.

Both ends of the U-tube are fixed on the same tube plate, and the shell and heat exchange tubes are separated. This allows the tube bundle to freely expand and contract without generating temperature difference stress, which is a problem that can occur in other types of heat exchangers.

U-shaped heat exchanger tubes have a simple structure which makes them easy to manufacture and maintain. They are commonly used in shell and U-tube heat exchangers, which consist of a cylindrical shell with U-shaped tubes inside. The U-tube design allows for better heat transfer efficiency, and the compact size of the U-shaped tubes means that the heat exchanger can be very powerful despite its small footprint.

Overall, U-shaped heat exchanger tubes are a popular choice for many industrial applications due to their simplicity, efficiency, and compact size.

U-tubes are made of precision straight tubes. These precision straight tubes are completed after cold rolling and bright annealing. In order to meet the technical conditions of our customers, every step of the process is strictly controlled.

U-tubes are mainly divided into two categories according to materials: stainless steel U-tubes and alloy steel U-tube