U-Shaped Monel 400 Tubes are seamless or welded tubes made from Monel 400, a

nickel-copper alloy (UNS N04400), bent into a U-shape for use in heat exchanger tubes and

boiler tubes. Conforming to standards like ASTM B163 and B165, these tubes are engineered for

high-pressure and high-temperature applications in industries such as marine, petrochemical, chemical processing,

and power generation. Their exceptional corrosion resistance to seawater, acids, and alkalis,

combined with their role as a thermal expansion absorber, makes them ideal for enhancing

pipeline durability in harsh environments.

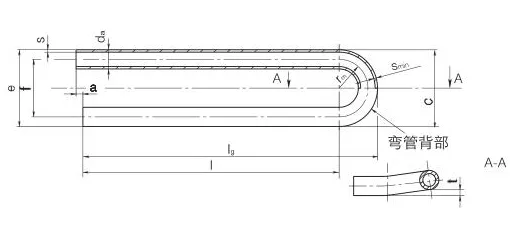

Manufactured through cold-drawing or hot-rolling processes, U-Shaped Monel 400 Tubes feature outer

diameters from 6.35mm to 50.8mm, wall thicknesses from 0.8mm to 6mm, and bend radii from 1.5D to 1500mm,

customizable to meet project specifications. Post-bending heat treatments, such as annealing at 870-980°C, ensure

optimal mechanical properties and prevent cracking. Surface treatments like pickling, passivation, or polishing

enhance corrosion resistance, while plastic caps protect tube ends during transport. The alloy’s

high nickel content (63-70%) and copper (28-34%) provide excellent resistance to chloride-induced stress corrosion

cracking.

These tubes undergo rigorous testing, including hydrostatic, eddy current, flaring, flattening, and hardness tests,

to comply with ASTM A450/A450M and TEMA standards. With a minimum tensile strength of 550 MPa and yield strength of

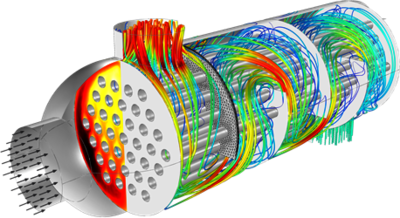

240 MPa, they are designed for temperatures up to 540°C and pressures up to 10 MPa. The U-shaped design minimizes

thermal stress, eliminates the need for expansion joints, and reduces installation costs, making them ideal for

compact heat exchanger systems in marine and chemical applications.

The Monel 400 alloy’s composition, with 63-70% nickel, 28-34% copper, and minor amounts of iron, manganese, carbon,

and silicon, ensures superior corrosion resistance in seawater, hydrofluoric acid, sulfuric acid,

and alkalis. Unlike other alloys, Monel 400 is hardened only by cold working, offering excellent weldability and

ductility. These tubes are particularly suited for marine applications like seawater piping, chemical plant

equipment, and crude oil distillation towers, as well as boiler feedwater heaters and condensers in power plants.

Addressing challenges like pipeline wear, corrosion, and thermal stress, U-Shaped Monel 400 Tubes

provide a robust solution for engineers seeking reliable heat exchanger tubes. Their high strength,

excellent machinability, and low maintenance requirements make them a preferred choice for critical applications in

corrosive and high-temperature environments, ensuring long-term performance and efficiency.

Monel Alloy 400

Monel alloy 400 is a high strength, corrosion resistant nickel alloy. It is incredibly versatile with a range of

applications, including the marine and chemical processing industry. We’ll take a look at the properties,

applications and chemical composition that make Monel 400 unique.

What is Monel 400?

Monel 400, also known as Alloy 400, is a nickel alloy supplied by NeoNickel. It has a high percentage of copper,

which makes it so corrosion resistant.

Chemical Composition (ASTM B163/B165)

| Element |

Composition (%) |

| Nickel (Ni) |

63.0-70.0 |

| Copper (Cu) |

28.0-34.0 |

| Iron (Fe) |

≤2.5 |

| Manganese (Mn) |

≤2.0 |

| Carbon (C) |

≤0.3 |

| Silicon (Si) |

≤0.5 |

| Sulfur (S) |

≤0.024 |

Mechanical Properties (ASTM B163/B165)

| Property |

Value |

| Tensile Strength, min (MPa) |

550 |

| Yield Strength, min (MPa) |

240 |

| Elongation, min (%) |

40 |

| Hardness, max (HRB) |

75 |

Monel 400 is a corrosion-resistant material that offers excellent resistance to a wide range of corrosive

environments, including seawater and various acids. It also exhibits high strength and good mechanical properties at

both high and low temperatures.

U-shaped Monel 400 tubes are typically used in heat exchangers, condensers, and other similar applications where a

U-shaped configuration is required. The U-shape allows for efficient heat transfer and can be advantageous in

situations where space is limited or where a compact design is desired.

These tubes are often manufactured by bending straight Monel 400 tubes into a U-shape using specialized bending

equipment. The bending process is carefully controlled to ensure that the tubes maintain their mechanical properties

and dimensional accuracy.

U-shaped Monel 400 tubes can be found in a variety of industries, including chemical processing, marine, oil and gas,

and power generation. They are valued for their corrosion resistance, high strength, and ability to withstand

extreme temperatures.

Monel 400® Pipe - Nickel Alloys

Monel 400® pipe meets the requirements of numerous industrial, international, MIL-SPEC, and other specifications.

These include:

- UNS N04400

- ASTM B165

- ASTM B829

- ASTM B775

- ASTM B725

- ASTM B163

- ASTM B730

- ASTM B751

- AMS 4574

- DIN 17752

- VdTUV 2635