Fin Tube

Enhanced Heat Transfer Solutions

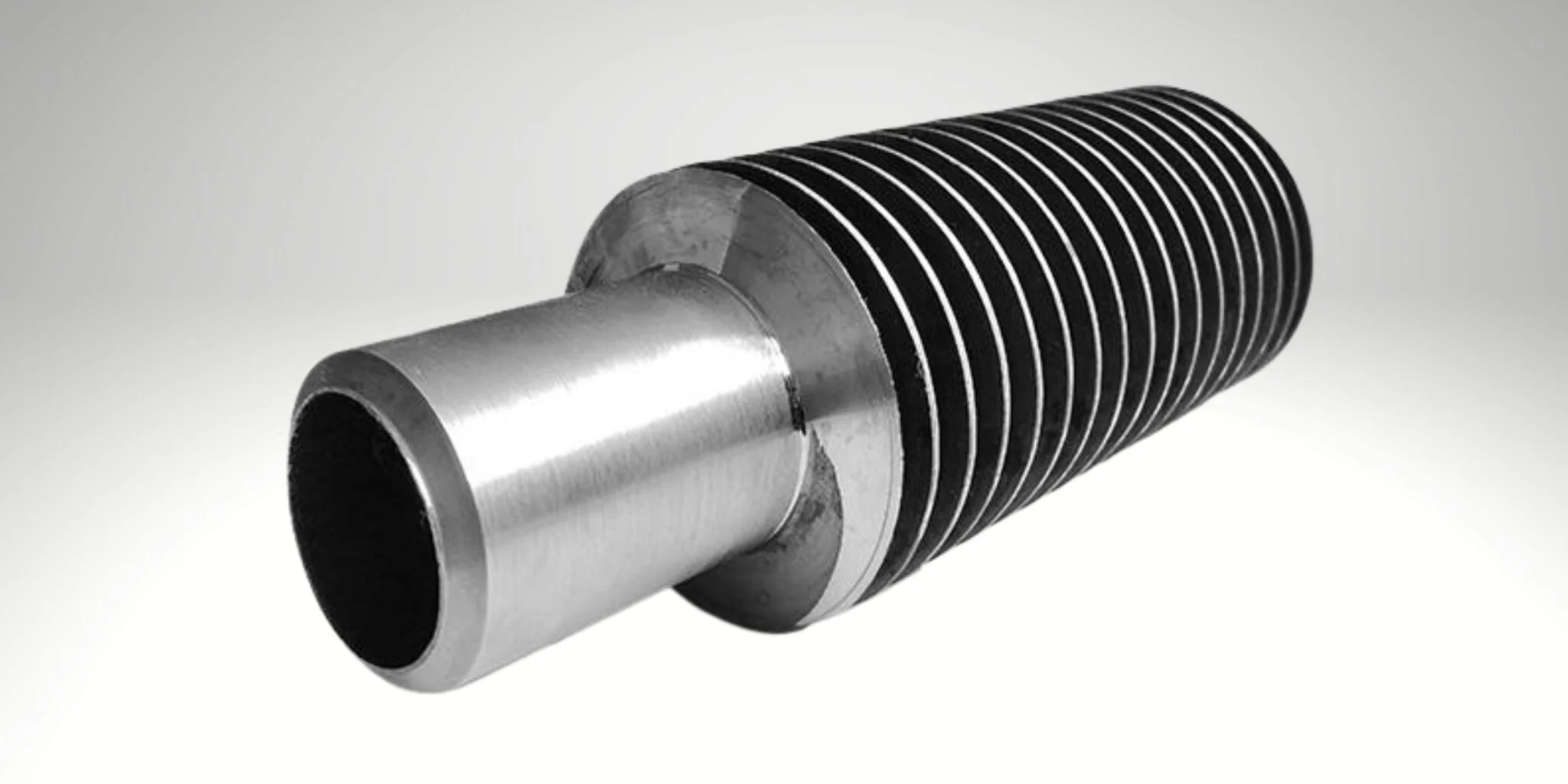

Fin tubes are specialized heat exchanger components designed to significantly increase heat transfer efficiency by enlarging the surface area for thermal exchange.

Enhanced Heat Transfer Solutions

Fin tubes are specialized heat exchanger components designed to significantly increase heat transfer efficiency by enlarging the surface area for thermal exchange.

Fin tubes are heat exchanger components used in applications involving the transfer of heat from a hot fluid to a colder fluid through a tube wall. They feature extended surfaces, or fins, which significantly increase the external surface area of the tube.

Fins significantly increase the external surface area, allowing for more efficient heat transfer between fluids.

Ideal for applications requiring high heat transfer rates, such as power plants and refrigeration systems.

Fewer tubes needed compared to plain tubes, decreasing overall equipment size and project costs.

Fin Tubes, also known as finned tubes or finned tubing, are specialized tubes with extended surfaces (fins) attached to enhance heat transfer efficiency in heat exchangers. Engineered for industrial applications, these thermal transfer tubes are widely used in petrochemical plants, power generation, HVAC systems, and air-cooled condensers. By increasing the surface area for convection, fin tubes significantly improve heat dissipation, making them essential for air cooled exchangers where air is the primary cooling medium.

Fin Tubes are manufactured using various methods, including extrusion, welding, or helical winding, to attach fins to base tubes made from materials like carbon steel, stainless steel, copper, aluminum, or alloys. Common types include L-finned (wrap-on), G-finned (embedded), KL-finned (knurled), and low-fin tubes, each suited for specific conditions. For instance, L-finned tubes offer cost-effective solutions for moderate temperatures up to 175°C, while embedded G-fins provide superior mechanical strength for high-stress environments. Available in sizes from 1/2" to 24" (DN15 to DN600) with fin densities of 5-11 fins per inch, finned tubing can be customized for straight lengths, coils, or U-bends to fit diverse heat exchanger fins designs.

The primary advantage of fin tubes lies in their ability to overcome low heat transfer coefficients on the air side, boosting overall efficiency by 5-8 times compared to plain tubes. They are ideal for applications involving gas-to-liquid or gas-to-gas exchanges, such as in boiler economizers, radiators, and refrigeration systems. Rigorous testing, including hydrostatic pressure, eddy current, and thermal performance evaluations, ensures compliance with standards like ASTM A179, A213, and TEMA. Surface enhancements like galvanization or epoxy coatings further improve corrosion resistance, making them suitable for harsh conditions involving seawater, acids, or high humidity.

In air cooled exchangers, fin tubes facilitate compact designs by minimizing the need for larger tube bundles, reducing material costs and space requirements. For example, in power plants, they efficiently cool turbine exhaust gases, while in petrochemical refineries, they handle corrosive process fluids. The fin geometry—such as pitch, height, and thickness—can be optimized for turbulent airflow, vibration resistance, and fouling prevention. Compared to plain tubes, heat exchanger fins enable smaller footprints and lower energy consumption, aligning with modern sustainability goals.

Fin Tubes also excel in maintenance efficiency, with designs that resist fouling and allow easy cleaning. Their versatility extends to specialized uses like marine desalination, where lightweight aluminum finned tubing withstands saltwater corrosion, or high-temperature boilers using alloy steel for creep resistance up to 650°C. By integrating thermal transfer tubes into systems, industries achieve enhanced performance, reduced operational costs, and prolonged equipment life, making them indispensable for reliable heat management solutions.

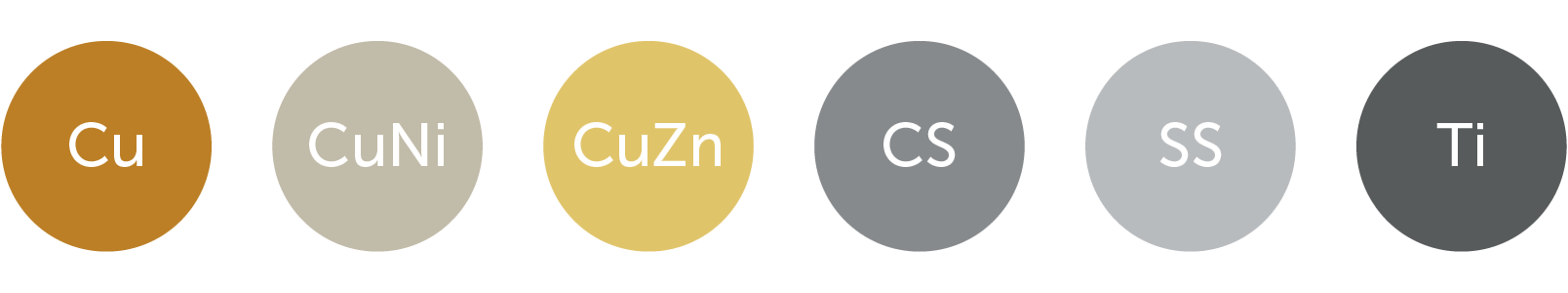

We offer you a broad portfolio of materials and can expand our offerings at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance.

For Aluminum L-Foot finned tubes, the fin material is aluminum, either 1100-0. The tube material is generally carbon steel, stainless steel, or brass; however the tube can be of any material.

For Welded Helical Solid and Welded Helical Serrated finned tubes, the fin and tube materials can be any combination that can be welded together using HIGH FREQUENCY WELDING process.

The materials chosen for a given application are a function of service temperature, corrosive environment, and/or erosive environment. Common tube materials used for our welded product lines include: carbon steel, carbon moly, chrome moly, stainless steel, Inconel, and Incoloy. Common fin materials include: carbon steel; stainless steels of types 304, 310, 316, 321, 409, and 410; Nickel 200, and Inconel.

We offer you a broad portfolio of materials and can expand our offering at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance.

| Material | Grade |

|---|---|

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3/Gr6/Gr8, A334 Gr3/Gr6/Gr8, 09CrCuSb, DIN 17175 St35.8/St45.8, EN 10216 P195/P235/P265, GB/T3087 Gr10/Gr20, GB/T5310 20G/20MnG |

| Alloy Steel Tubes | A209 T1/T1a, A213 T2/T5/T9/T11/T12/T22/T91, A335 P2/P5/P9/P11/P12/P22/P91, EN 10216-2 13CrMo4-5/10CrMo9-10/15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L, TP310/310S, TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Our finned tubes

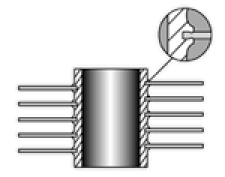

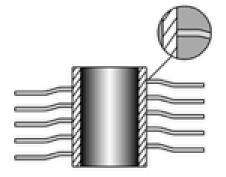

The “G” stands for “grooved,” referring to the method of attaching the fin to the tube. The

fin strip is wound into a groove and securely locked in place by closing the groove with the

base tube metal.

This design guarantees efficient heat transfer, even at high temperatures, with a maximum

operating temperature of 450ºC.

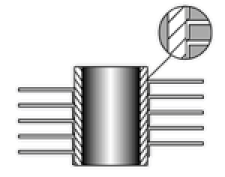

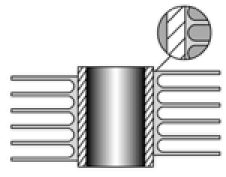

The “L” stands for “L-footed,” referring to the shape of the fin and how it’s attached to

the base tube. The strip material is precisely deformed under tension to create optimal

contact pressure between the fin’s foot and the base tube.

This maximizes heat transfer efficiency and significantly enhances the corrosion protection

of the base tube. Maximum operating temperature: 150ºC.

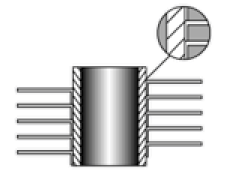

A KL fin is a specialized type of finned tube. It combines the benefits of L fins and G fins

for enhanced heat transfer and mechanical stability.

After the fin is applied, the fin foot is knurled into the matching knurling on the base

tube, strengthening the bond between the fin and tube and improving heat transfer

efficiency. Maximum operating temperature: 260ºC.

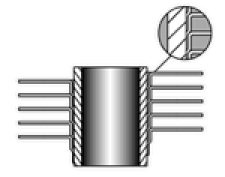

The “LL” stands for “overlapped L-footed fin,” describing the method of attaching the fin to the base tube.

Similar to the L fin, but with the added feature of overlapping the fin foot to fully enclose the base tube, this design offers superior corrosion resistance.

LL fins are often used as a cost-effective alternative to more expensive extruded fins in corrosive environments. Maximum operating temperature: 180ºC.

A crimped fin has a wavy, non-tapered shape that increases surface area and airflow turbulence, enhancing heat transfer efficiency.

The fin is wrapped under tension around the base tube, forming a crimp at the foot, and is then welded to the tube at the strip ends. Maximum operating temperature: 250ºC.

Created by extrusion, an extruded fin offers a strong, integrated bond between the fin and the base tube. Formed from a bi-metallic tube, it typically has an aluminum outer layer and an inner tube of various materials.

The fin is rolled from the outer tube, providing excellent heat transfer properties, durability, and corrosion protection. These fins are ideal for demanding thermal applications, with a maximum operating temperature of 280ºC.

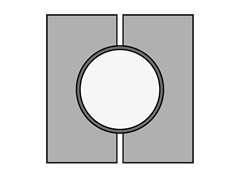

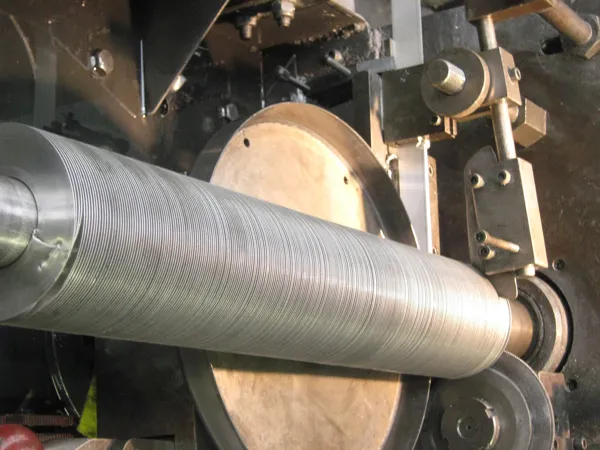

In an integral low fin, the fins are directly formed from the base tube material, creating a low-profile design.

This fin type increases the tube’s external surface area, improving thermal performance without requiring changes to the heat exchanger’s shell size, flow arrangement, or piping.

Integral low fins are created through direct extrusion from the tube material.

The maximum operating temperature for integral low fin tubes typically ranges between 200°C to 300°C, depending on the material used.

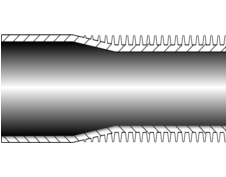

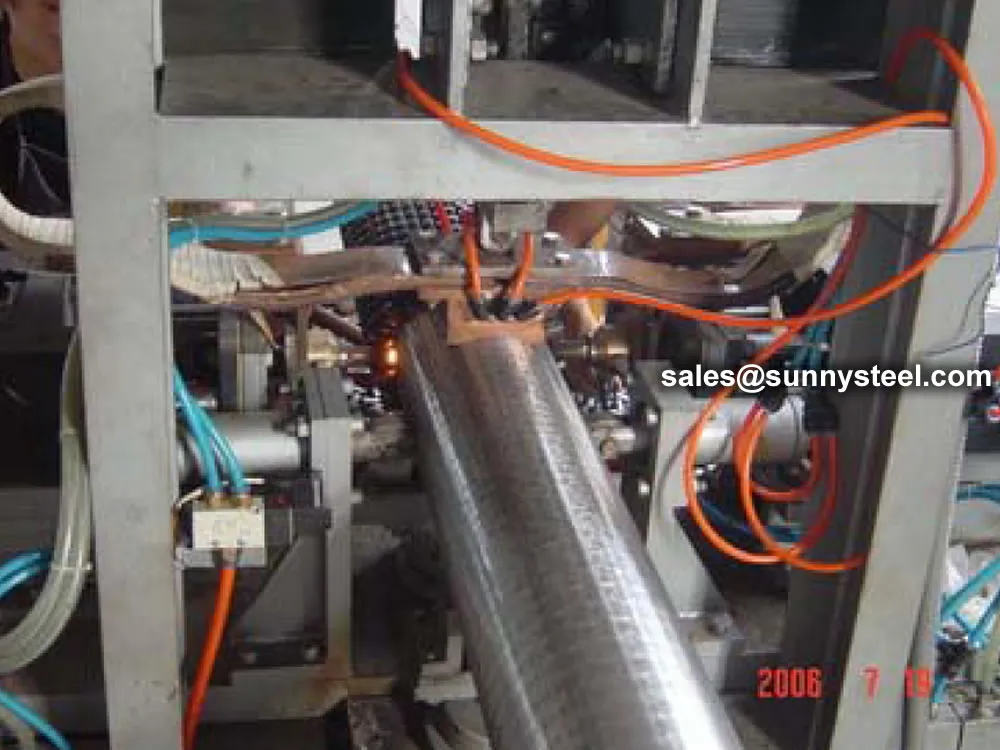

In a welded fin, the fins are attached to the base tube through welding. High-frequency (HF) welded spiral finned tubes are among the most commonly used, made by helically winding the fin strip around the tube and welding it continuously.

This process maintains the tube’s metallurgical integrity while ensuring a strong fin-to-tube bond, ideal for efficient heat transfer and long life.

These tubes are especially suited for fouling applications and environments where high mechanical strength and resistance to deformation are required.

Our factory is equipped with professional technical research and design personnel who can provide product optimization design and services.

Quality is the foundation of an enterprise. We adopt advanced production equipment and experienced technical personnel, constantly improve product technology, strictly control every processing step, and strive to compete with first-class quality products.

Testing instrument

Hardness tester

Drawing Machine

Component analyzer

Aluminium KL finned tube

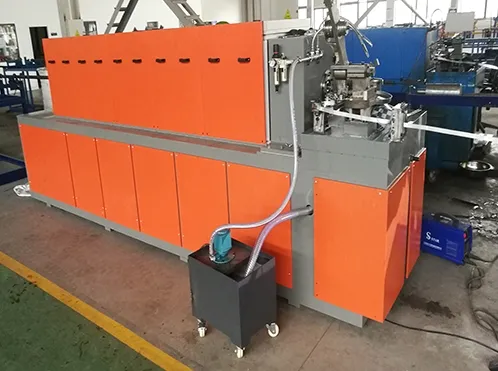

L LL KL G production line

Production equipments

Extrusion equipment

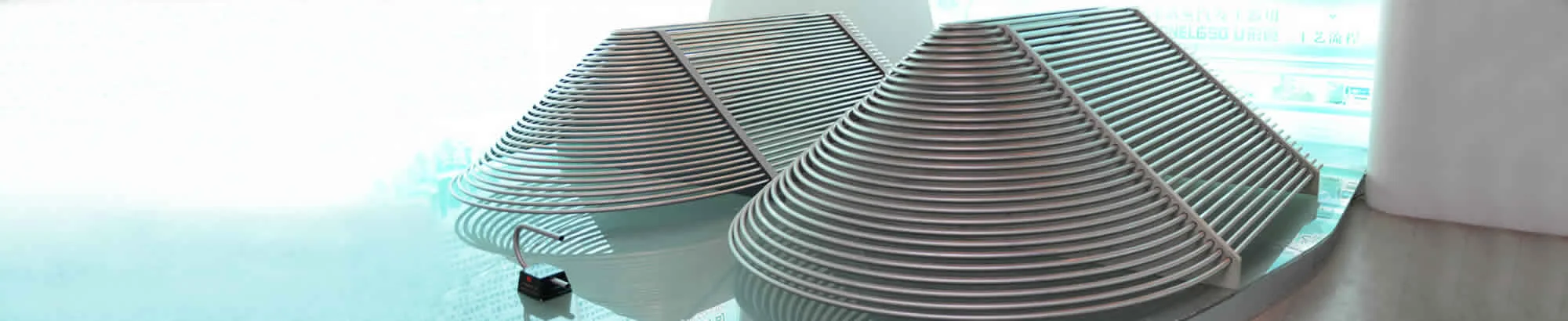

Fin tube bending

Finned tubes are available in many types and configurations. Below is a detailed classification based on fabrication process, fin geometry, material, and applications.

Fin tubes are a type of heat exchanger used in many industries. They are made of aluminum cladded carbon steel and have brazed aluminum fins. The fins increase the surface area of the tubes, which allows them to transfer heat more efficiently. This makes them ideal for applications where high heat transfer rates are required.

Finned tubes are used in applications that involve the transfer of heat from a hot fluid to a colder fluid through a tube wall. They are used in condensers, coolers, and furnaces. The larger surface area means that fewer tubes are needed compared to the use of plain tubes.

The type of finned tube is chosen depending on the specific requirements of each process equipment unit. The fin type and combination of materials are chosen based on the specific requirements of each process equipment unit.

Finned tubes are used in applications where high heat transfer rates are required, such as in power plants and refrigeration systems. The fins increase the surface area of the tube, allowing for more efficient heat transfer between two fluids. This makes them an ideal solution for heat transfer applications where space is limited.

Finned tubes are used in condensers, coolers, and furnaces. The larger surface area means that fewer tubes are needed compared to the use of plain tubes. This can decrease the overall equipment size and can in the long-run decrease the cost of the project.

Finned tube heat exchangers can be used in a broad range of industries including oil & gas, power generation, marine and HVAC&R. They generally use air to cool or heat fluids such as air, water, oil or gas, or they can be used to capture or recover waste heat.

The biggest problem with using a finned tube heat exchanger is with the cleaning and maintenance of the outer surface of the tubes. Because of the fins, mechanical cleaning becomes very difficult and you would have to go for chemical cleaning.

Fin tubes are a type of heat exchanger that are used in many industries. They have a finned surface, which increases their surface area and allows them to transfer heat more efficiently. Finned tubes are typically used in two-phase heat transfer applications, such as condensation or evaporation.

Finned pipes are generally used for single-phase heat transfer applications. Both finned pipes

and finned tubes use fins to increase the surface area for heat transfer.

Finned tubes are used when the heat transfer coefficient on the outside of the tubes is

appreciably lower than that on the inside. They can reduce the equipment cost and also equipment

sizes.

There are several kinds of fin tubes, such as:

High fin tubes are better for applications where the temperature difference between two fluids is high. Low fin tubes are better for applications where the temperature difference is low.

High fin tubes are made of a metal tube surrounded by an aluminum or copper strip. The strip can be applied in different ways, including type L, type KL, type LL, type G (embedded), or type extruded. The higher the fin height, the more surface area and heat transfer capabilities.

Low fin tubes are made of a single material and have a smaller fin of about 1/16th of an inch. They are generally used in liquid to liquid or liquid to gas applications such as coolers, condensers, and chillers.

The profile of the fins has a significant effect on the performance of a finned tube heat exchanger. The larger the fins and the tighter the fin pitch, the more thermal conductivity is achieved.

Finned tubes are a series of tubes with fins on the outside. The fins increase the surface area for heat transfer, which increases the rate of heat exchange. Finned tubes are used in heat exchangers to transfer heat between hot and cold streams. The heat transfer rate depends on the temperature difference between the two fluids and the heat transfer coefficient between each of the fluids.

Finned tube heat exchangers are used in a variety of industries, including:

Finned tube heat exchangers can be used to:

Regular cleaning to prevent fouling, with coatings for corrosion resistance; inspect for wear in high-vibration areas.

Fin tubes are widely used in heat exchangers for industries such as petroleum, petrochemical, steel, power generation, and many more. Different fabrication technologies determine their cost, performance, and efficiency. Below are the main types of fin tube production methods.

Fabricated with punched single fins manually or mechanically placed on the base tube at a certain spacing.

Manual set: Relies on human force; easy to loosen.

Mechanical set: High pressure, stronger bonding, suitable for larger volumes, but noisy and less safe.

Hydraulic set: Quieter, safer, but higher cost and lower productivity.

Produced by winding a steel strip around the tube while applying high-frequency current (skin and proximity effects).

Heat brings the material to a plastic/melt state, ensuring strong bonding under pressure.

Advantages:

- High bonding strength

- Superior quality

- High automation & efficiency

- Widely used in waste heat recovery, power, metallurgy, oil & gas, and petrochemical industries

Made by extruding an outer aluminum or copper tube (muff) over a base tube. Rotating discs squeeze the fins

into a spiral in one operation.

Advantages:

- High production efficiency

- Strong fin-to-tube contact

- Low material cost

- High heat transfer performance

Available as single-metal (copper/aluminum) or bi-metal composite tubes.

Pipe flanges are basically plates or rings used to...

A buttweld pipe fitting is a weldable component us...

Weldolets provide strong, corrosion-resistant bran...

U bend tubes are meticulously crafted for heat exc...

Industrial valves are critical devices used to con...

Pipe couplings are essential fittings for connecti...