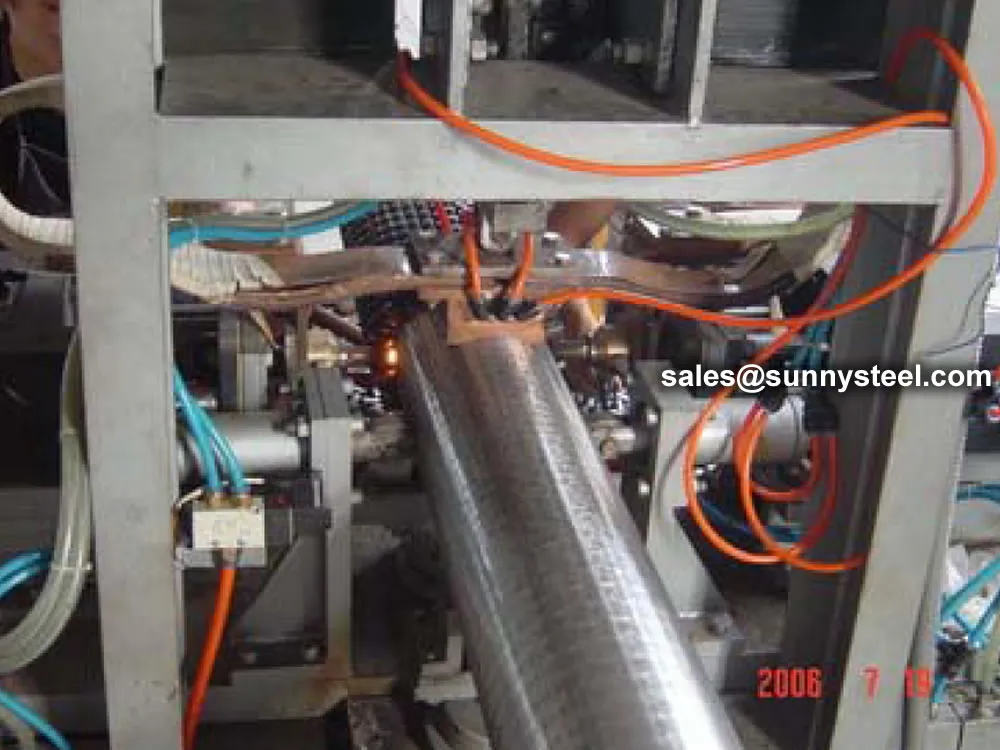

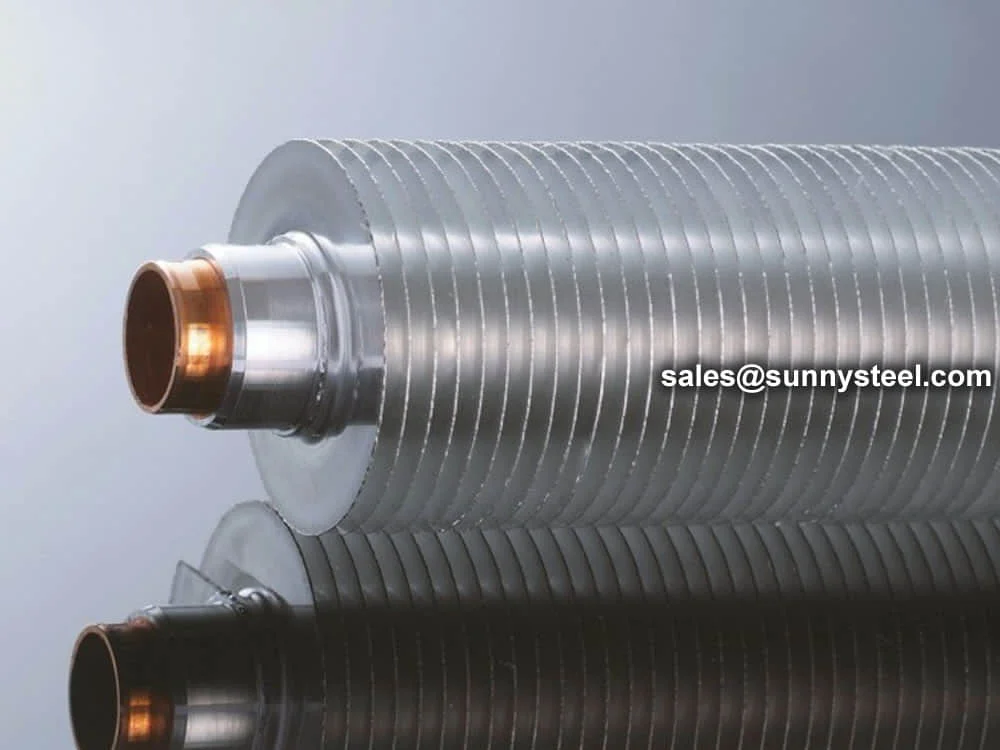

Crimped Fin Tubes, also known as spiral tension wound finned tubes, are advanced heat exchanger fins designed to maximize thermal transfer in air cooled exchangers. These tubes feature fins spirally wrapped under tension onto the base tube, typically without welding but with spot welding at the ends, ensuring a secure bond. Conforming to standards like ASTM A179, A213, and ASME SB338, crimped fin tubes are widely used in industries such as petrochemical, power generation, HVAC, and chemical processing due to their corrosion resistance and high heat transfer efficiency.

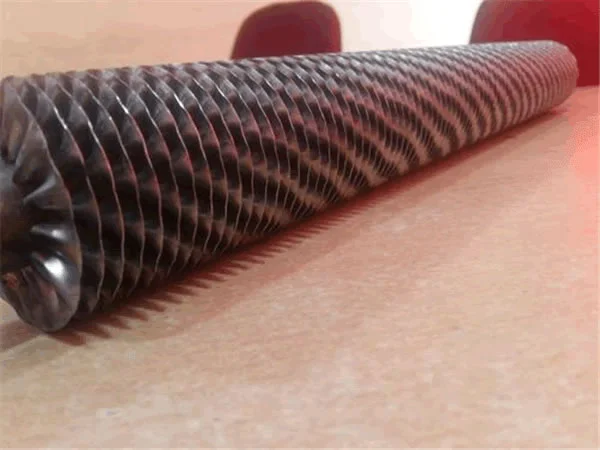

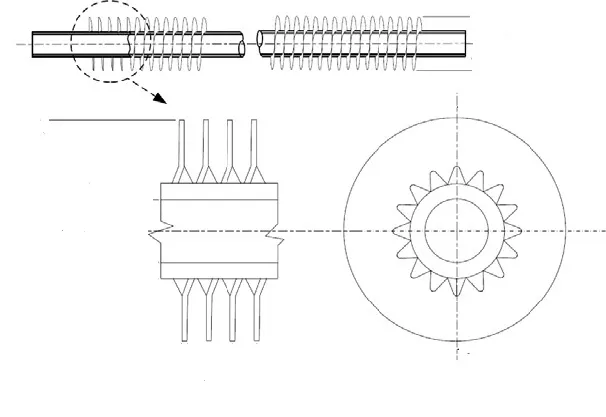

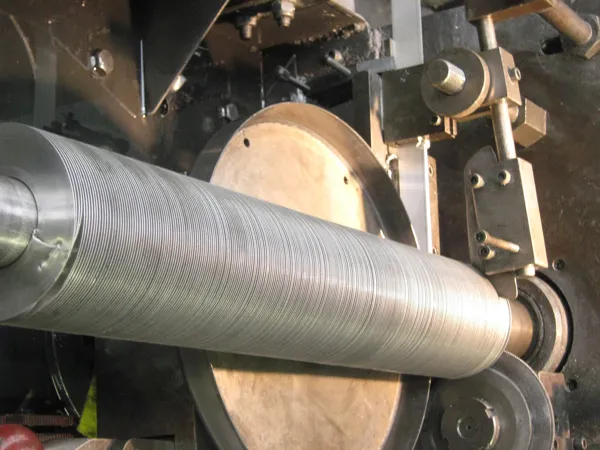

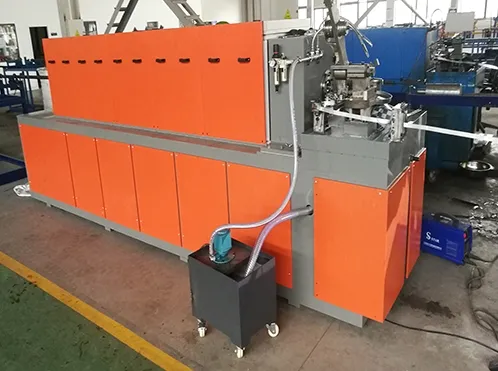

Manufactured through a specialized process, crimped fin tubes involve tension winding of fin material (aluminum, copper, carbon steel, or stainless steel) onto base tubes made of similar materials. The fin strip is pre-formed using rollers to create a crimped, wavy pattern, increasing the contact area and promoting turbulent airflow for enhanced heat transfer. Base tube outer diameters range from 15.88mm to 51mm, with fin heights up to 16mm and fin pitches of 3.5-10mm. These tubes are suitable for temperatures up to 180°C and are customizable in lengths up to 15 meters, with plain or beveled ends for easy installation.

Crimped Fin Tubes undergo rigorous testing, including hydrostatic, eddy current, and thermal performance tests, to ensure compliance with ASTM A450/A450M and TEMA standards. The crimped design provides moderate mechanical resistance and good corrosion protection, especially when using stainless steel or copper, making them ideal for environments with high humidity or corrosive fluids like seawater. Surface treatments such as galvanization, 3LPE coating, or tinning further enhance durability, while the fin design minimizes fouling and ash accumulation, ensuring low maintenance.

Compared to other finned tubes like L or G types, crimped fin tubes offer higher airside turbulence due to their corrugated fin structure, resulting in up to 5-8 times greater heat transfer efficiency than plain tubes. They are particularly suited for air cooled exchangers in applications like air heaters, condensers, and boiler economizers, where compact designs and energy efficiency are critical. Their cost-effectiveness compared to high-frequency welded (HFW) fin tubes makes them a preferred choice for moderate-temperature applications.

Addressing challenges like pipeline corrosion and thermal inefficiency, crimped fin tubes provide a robust solution for engineers seeking reliable thermal transfer tubes. Their versatility, ease of installation, and ability to handle high-pressure fluids make them essential for demanding environments, ensuring long-term performance and reduced operational costs in heat exchanger fins systems.