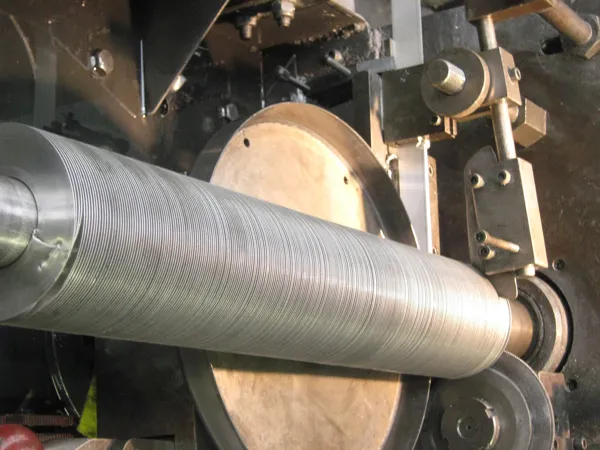

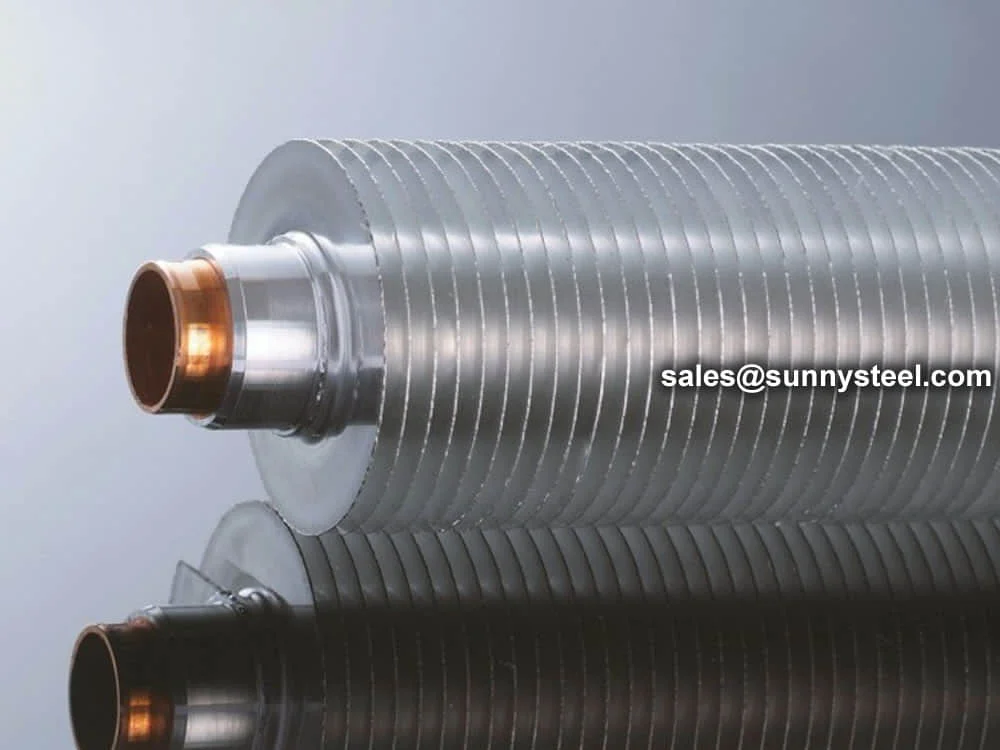

Longitudinal Finned Tubes are specialized heat exchanger fins designed to enhance thermal transfer by increasing the surface area of the tube through fins welded longitudinally along its length. These welded finned tubes are produced using high-frequency resistance welding, ensuring a robust bond suitable for high-temperature and high-pressure applications. Conforming to standards like ASTM A179, A213, and ASME SB338, they are widely used in petrochemical, power generation, boiler systems, and air coolers, providing excellent corrosion resistance and boiler pipeline protection.

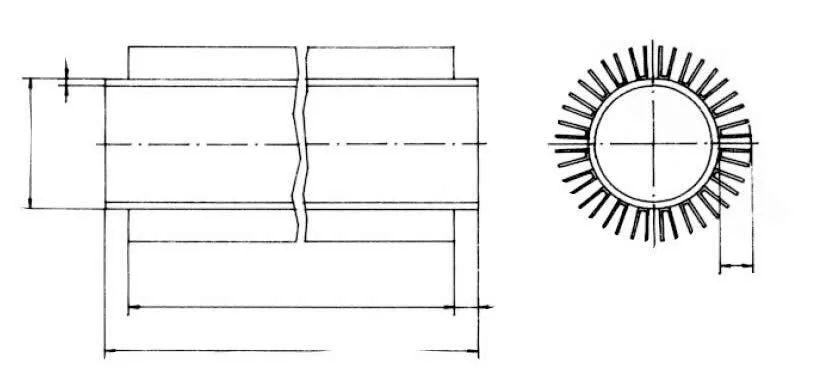

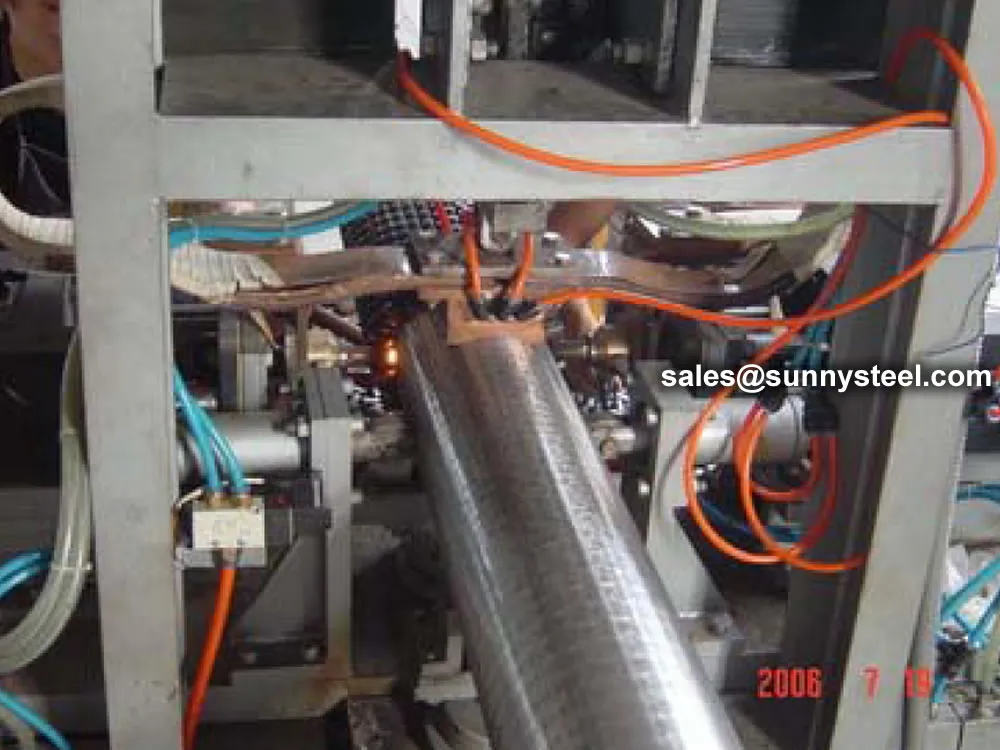

Welded Longitudinal Finned Tubes are produced by resistance welding fins in the longitudinal direction along the length of the tube. The fin strip is first formed into a U-shaped channel, such that each leg of the U will form a fin. The channels are cut to the appropriate length and then oriented along the length of the tube and resistance welded in place. The channels are welded in pairs, diametrically opposed — therefore the number of fins specified must always be a multiple of four.

Longitudinal Finned Tubes undergo stringent testing, including hydrostatic, eddy current, tensile, and flattening tests, to ensure compliance with ASTM and TEMA standards. Their design promotes turbulent fluid flow, enhancing heat transfer efficiency by 8-12 times compared to plain tubes, particularly in gas-to-liquid or gas-to-gas applications. The tubes can be configured with perforated fins or cut-and-twist designs to further improve heat transfer by disrupting laminar flow. Suitable for temperatures up to 400°C and pressures up to 10 MPa, they are ideal for boiler pipeline protection in high-stress environments.

These tubes excel in applications like horizontal heat exchangers, air preheaters, and waste heat recovery systems, where their compact design reduces equipment size and material costs. Compared to helical finned tubes, longitudinal finned tubes offer superior drainage for viscous liquids, reducing fouling and maintenance needs. Their robust construction ensures durability in abrasive or corrosive environments, such as petrochemical refineries or power plant boilers, where they handle fluids like crude oil, steam, or exhaust gases.

Addressing challenges like pipeline wear, corrosion, and thermal stress, longitudinal finned tubes provide a reliable solution for engineers seeking efficient thermal transfer tubes. Their versatility, including U-bend or single-piece configurations, makes them adaptable to complex systems, ensuring long-term performance and energy efficiency in demanding industrial applications.