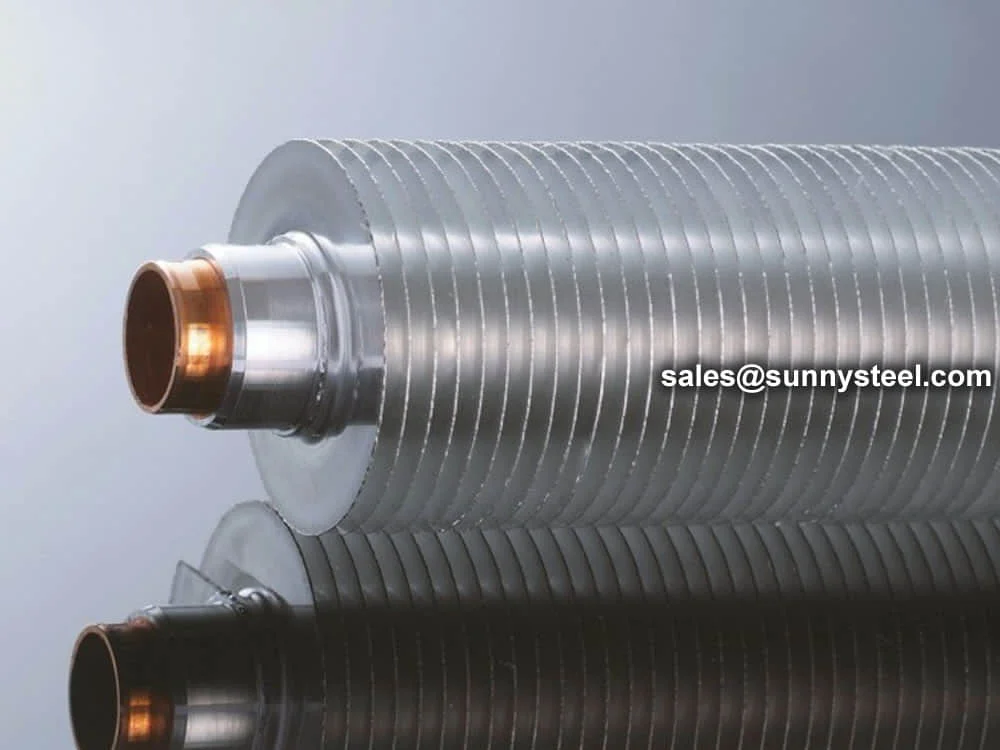

Helical Solid Finned Tubes are advanced heat exchanger fins

engineered to maximize thermal transfer by increasing the external surface area through a

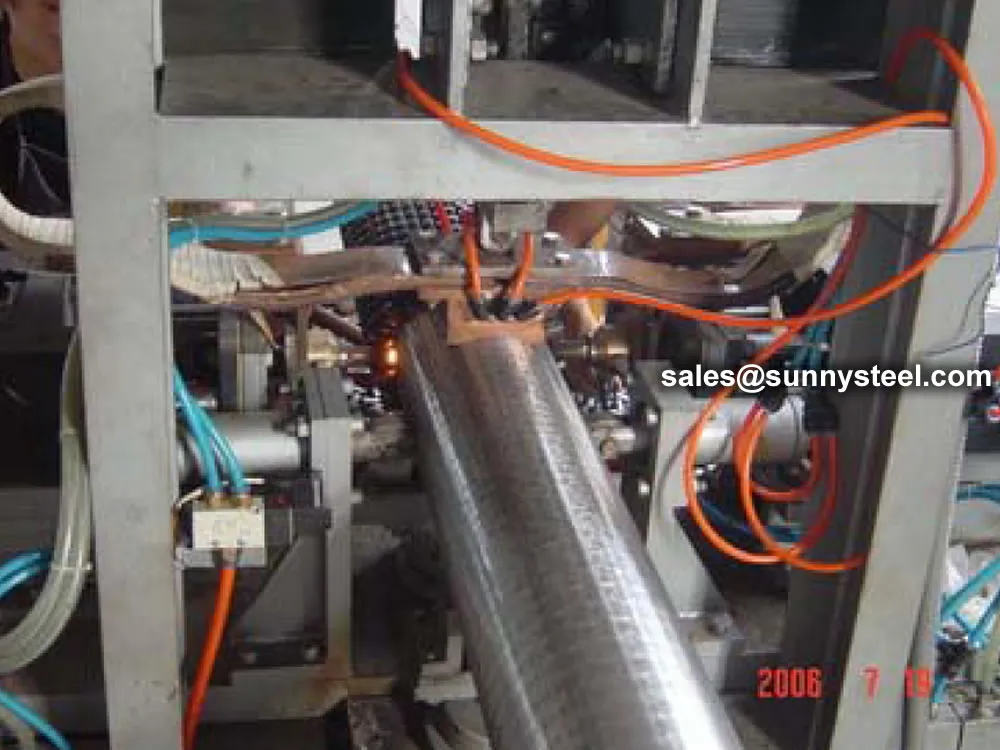

continuous fin strip spirally welded onto the base tube. These welded finned tubes utilize

high-frequency resistance welding (HFRW) or gas metal arc welding (GMAW) to ensure a robust fin-to-tube bond, ideal

for high-temperature and high-pressure environments. Conforming to standards like ASTM A179, A213, and ASME SB338,

they are widely used in petrochemical, power generation, industrial boilers, and air-cooled heat exchangers,

offering exceptional corrosion resistance and boiler pipeline protection.

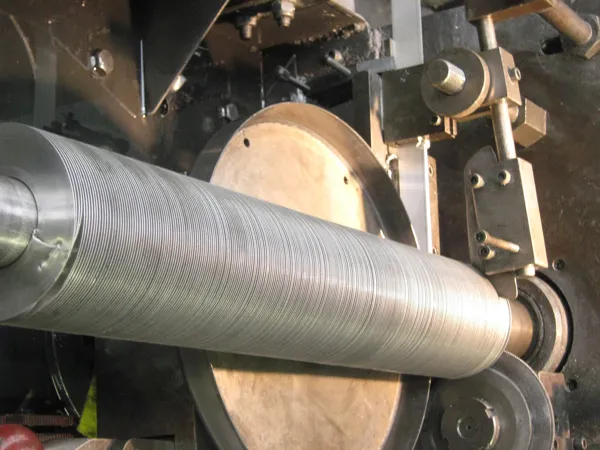

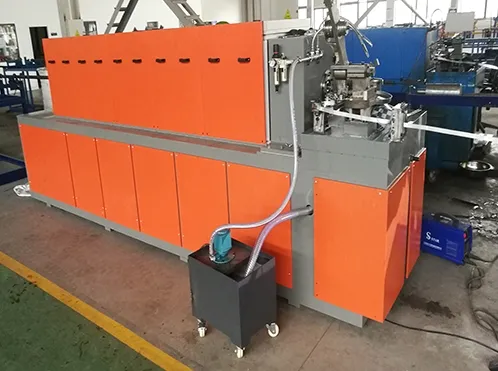

The manufacturing process involves helically wrapping a fin strip (typically carbon steel, stainless steel, or

aluminum) under tension around the base tube, followed by continuous welding to ensure strong contact and minimal

thermal resistance. Base tube sizes range from 16mm to 273mm (10” OD), with fin heights of 10mm to 25mm, fin

thicknesses of 0.8mm to 1.5mm, and fin pitches of 80 to 230 fins per meter. These tubes can be customized for

lengths up to 20 meters, with plain or beveled ends for seamless integration into heat exchanger

fins systems. Surface treatments like galvanization, 3LPE, or epoxy coatings enhance corrosion

resistance, making them suitable for harsh environments involving seawater, acidic gases, or abrasive

slurries.

Helical Solid Finned Tubes undergo rigorous testing, including hydrostatic, eddy current, tensile,

and thermal performance tests, to meet ASTM A450/A450M and TEMA standards. Their helical fin design creates

turbulent airflow, improving the heat transfer coefficient by 4-5 times compared to plain tubes, making them ideal

for air cooled exchangers and boiler systems. The continuous weld ensures excellent heat transfer

characteristics, low fin-side pressure drop, and minimal grain microstructure changes, even with high-chromium tubes

(3%-9% Cr). These tubes are particularly suited for applications requiring high thermal efficiency, such as waste

heat recovery and petrochemical refining.

Compared to longitudinal finned tubes, helical solid finned tubes offer superior heat transfer due

to their spiral geometry, which enhances turbulence and reduces fouling. They are commonly used in air-cooled heat

exchangers, boiler economizers, and fired heaters, where their compact design reduces material costs and equipment

footprint. The ability to weld dissimilar materials (e.g., aluminum fins on stainless steel tubes) allows

customization for specific thermal and corrosion requirements, making them versatile for diverse industrial

applications.

Addressing challenges like pipeline wear, corrosion, and thermal stress, helical solid finned tubes

provide a durable and efficient solution for thermal transfer tubes. Their robust construction and

high heat transfer efficiency make them a preferred choice for engineers seeking reliable performance in demanding

environments, ensuring long-term durability and energy efficiency in boiler pipeline protection and

heat exchanger systems.

Key Features

- Continuous MIG welding ensures high heat transfer coefficient (4–5× conventional fins)

- Ability to weld dissimilar materials for specialized applications

- Customizable fin height, pitch, and material selection

- Applicable for both air-cooled and liquid-cooled heat exchangers

- Ideal for power, HVAC, chemical, and petrochemical industries

Specifications of Helical Solid Finned Tubes (Finned Tubes/Pipes)

| Parameter |

Details / Range |

| Tube/Pipe Size |

16 mm to 273 mm (10”) and more on request |

| Tube/Pipe Material |

Carbon Steel (A106, A333, A179, A210, P5, P11, P22) + Stainless Steel (304, 316, Duplex, Super Duplex) + Nickel Alloys (Monel 400, Inconel 625) |

| Fin Material |

Carbon Steel (A106, A333, A179, A210, P5, P11, P22) + Stainless Steel (304, 316, Duplex, Super Duplex) + Nickel Alloys (Monel 400, Inconel 625) |

| Fin Height |

10 mm to 25 mm and more on request |

| Fin Thickness |

1.2 mm to 1.5 mm (corrected decimal separator for consistency) |

| Number of Fins |

From 80 fins/meter to 230 fins/meter |

FAQs

Engineered to meet diverse industrial needs with robust materials and versatile designs.

Helical Solid Finned Tubes are welded finned tubes with spiral fins welded onto the base tube to enhance thermal transfer in heat exchanger fins.

Used in air cooled exchangers, boiler economizers, fired heaters, and waste heat recovery in petrochemical and power industries.

Carbon steel, stainless steel, aluminum, or nickel alloys with coatings for corrosion resistance.

Suitable for temperatures up to 400°C, depending on material and welding method.

Spiral fins increase surface area and turbulence, boosting thermal transfer by 4-5 times.

Base tube OD: 16-273mm, fin height: 10-25mm, fin pitch: 80-230 fins/m, lengths up to 20m.

High-frequency resistance or gas metal arc welding of spiral fins onto the base tube.

Hydrostatic, eddy current, tensile, and thermal tests ensure ASTM A450/A450M and TEMA compliance.

Welded or expanded into tube sheets in air cooled exchangers for optimal airflow.

Helical Solid Finned Tubes offer higher turbulence and heat transfer efficiency than longitudinal fins, ideal for gas-to-liquid applications.