Oval Fin Tubes, also known as oval finned tubes or finned

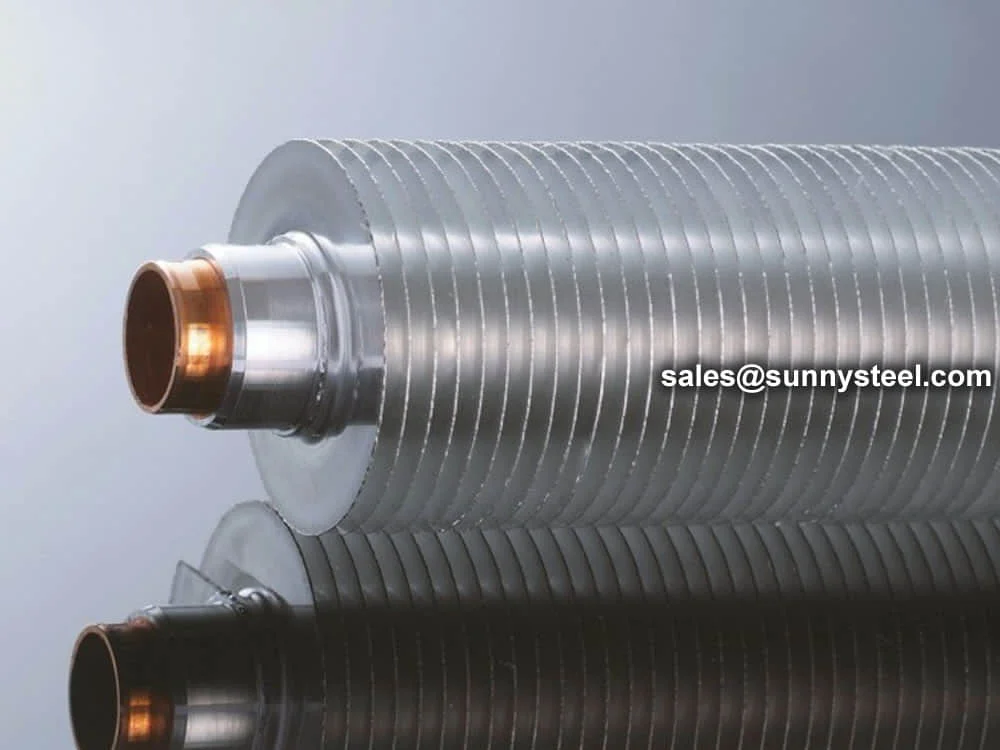

oval tubes, are specialized heat exchanger fins featuring an oval-shaped base tube

with external rectangular or spiral fins to maximize thermal transfer. These thermal

transfer tubes are engineered for high-efficiency heat exchange in industries like petrochemical, oil

refining, ethylene production, and power generation. Conforming to standards such as ASTM A179, A213, and TEMA,

oval fin tubes outperform traditional round finned tubes by reducing air-side flow resistance and

enabling compact layouts, making them ideal for air cooled exchangers and space-constrained

applications.

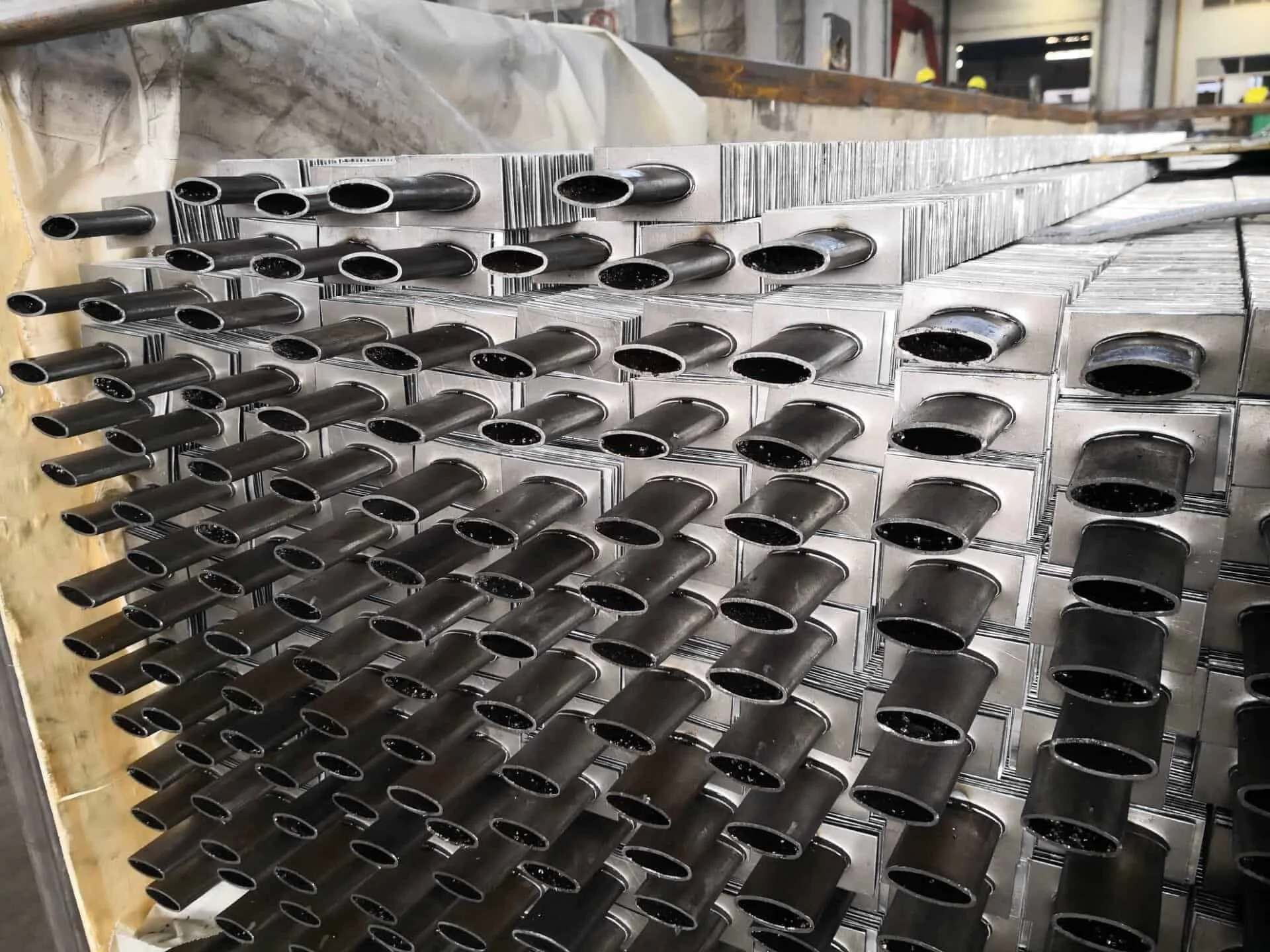

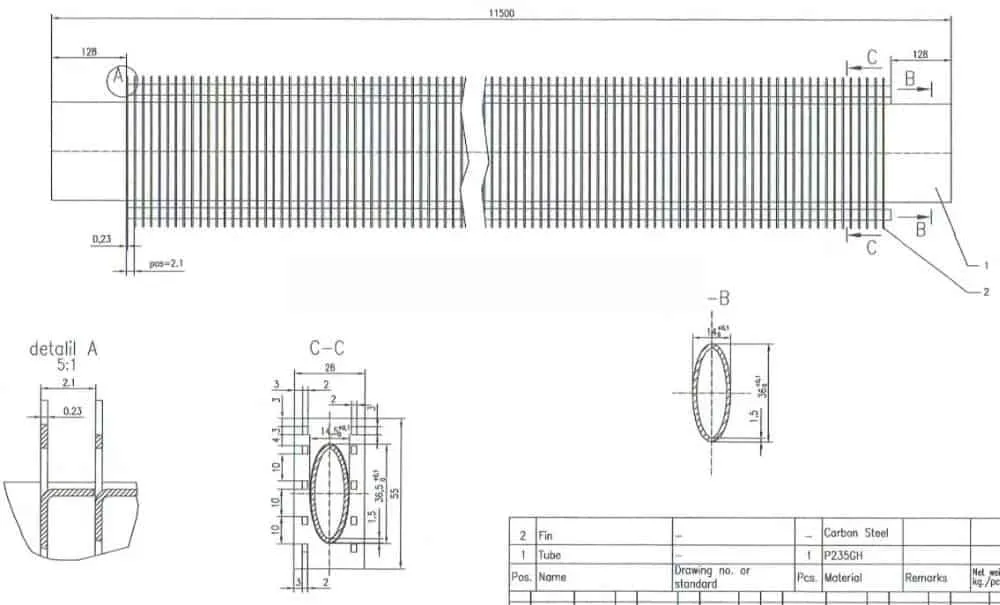

The unique oval geometry of the base tube minimizes the wake region and windward area compared to circular tubes,

effectively lowering pressure drop and energy consumption while increasing the heat transfer coefficient between

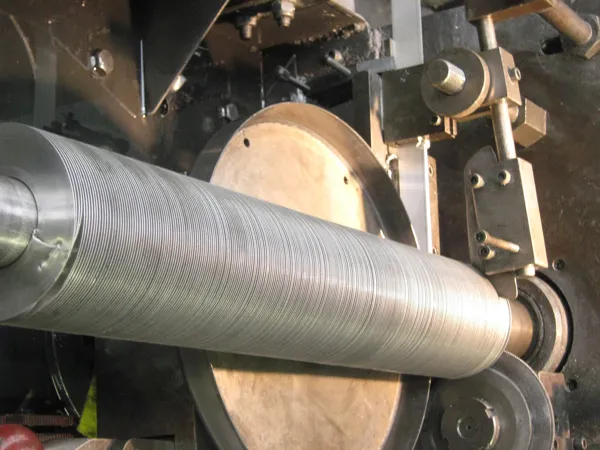

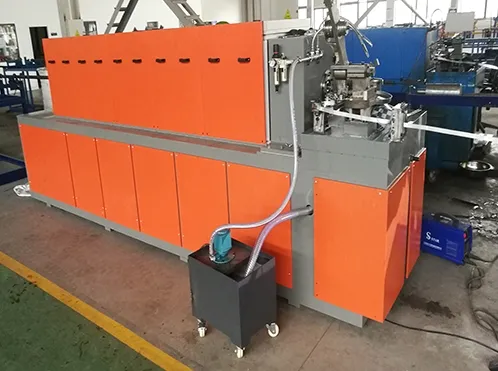

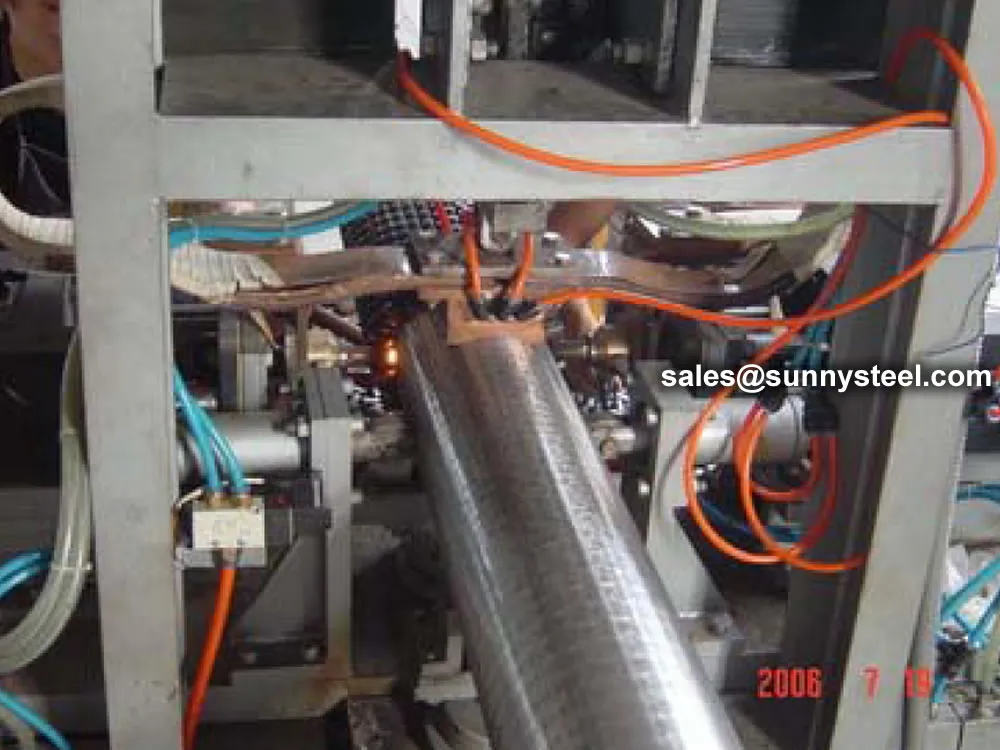

fluids. Oval Fin Tubes are manufactured by spirally wrapping aluminum, copper, or steel fin strips

around the oval base tube, often using tension winding or high-frequency welding for a secure bond. Available in

variants like oval rectangular finned tubes, oval-oval finned tubes, oval circular finned tubes, and spiral oval

flat tubes, they support fin heights of 8-15mm, fin pitches of 3.5-10mm, and base tube dimensions from 15.88mm to

51mm outer diameter. Custom lengths up to 15 meters and hot-dip galvanization enhance corrosion

resistance, ensuring durability in harsh environments like seawater or acidic gases.

Oval Fin Tubes undergo rigorous quality testing, including hydrostatic, eddy current, flaring, and

thermal performance evaluations, to meet ASTM A450/A450M and TEMA standards. Their design promotes turbulent

airflow, boosting heat transfer efficiency by up to 19% and reducing overall heat exchanger volume by 32% compared

to round tubes. The oval shape allows for denser tube arrangements, saving space and material costs without

compromising performance. In applications like waste heat recovery, boiler economizers, and compressor coolers,

these tubes handle temperatures up to 260°C and pressures up to 10 MPa, with excellent resistance to fouling and

vibration.

Compared to round finned tubes, finned oval tubes exhibit smaller reflux and windward areas,

leading to lower air-side resistance and higher fluid-side heat transfer. This makes them particularly advantageous

in compact heat exchangers for oil refineries and petrochemical plants, where space efficiency and energy savings

are critical. Optional features like serrated or perforated fins further optimize performance by disrupting laminar

flow and enhancing volumetric heat flux density. Surface protections such as 3LPE coatings or galvanization provide

robust corrosion resistance, extending service life in corrosive media.

In practical use, oval fin tubes address key challenges like high energy consumption and large

footprints in traditional heat exchangers. Their superior thermal performance and compact design make them a go-to

solution for engineers seeking reliable thermal transfer tubes in demanding industrial settings.

Whether in air-cooled condensers or refrigeration systems, these tubes deliver unmatched efficiency, durability, and

cost savings, supporting sustainable operations in petrochemical, power, and HVAC applications.