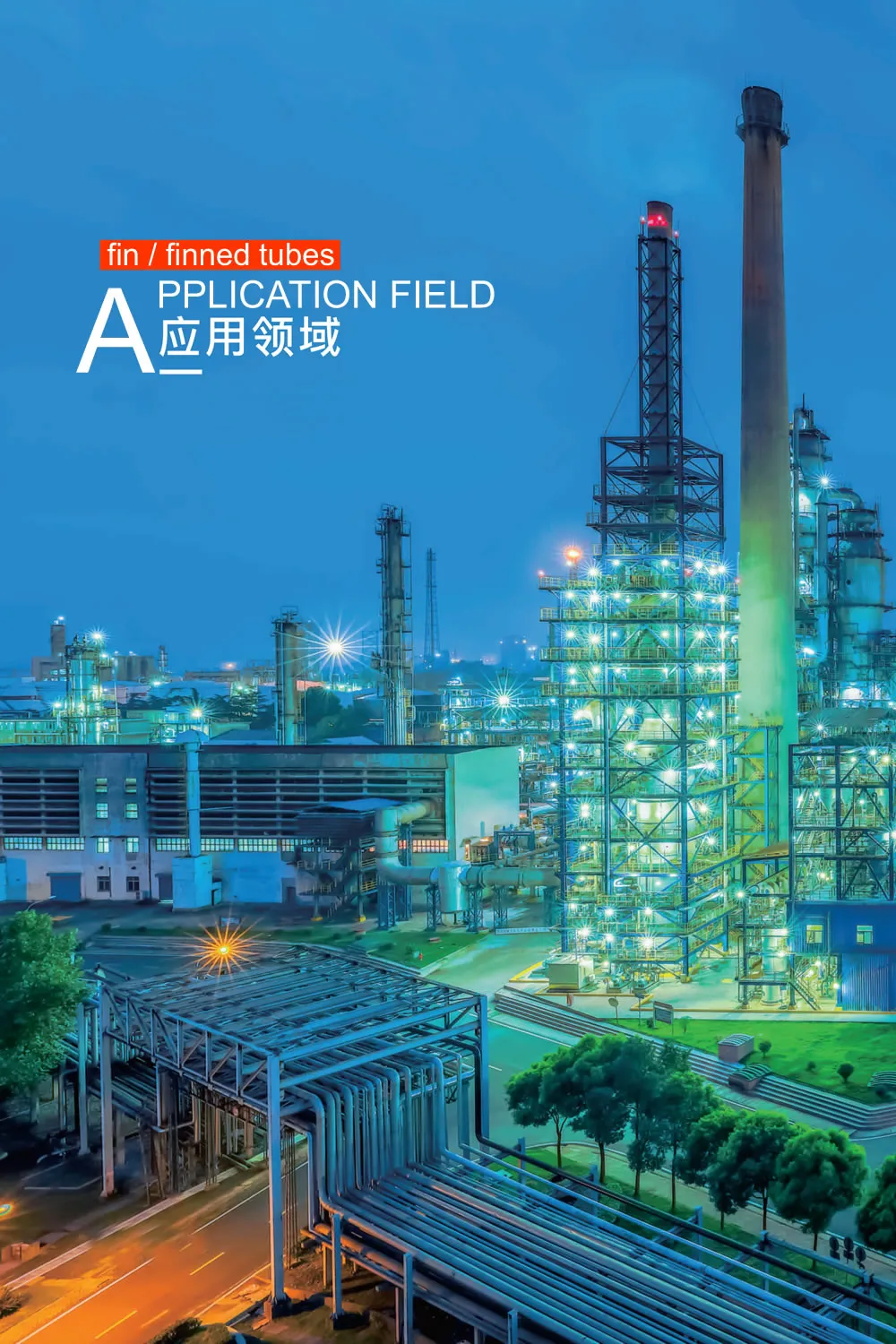

Fin Tubes are used in

heat exchangers to enhance

thermal

transfer by increasing surface area, ideal for air-cooled systems in petrochemical and

power industries.

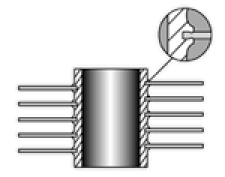

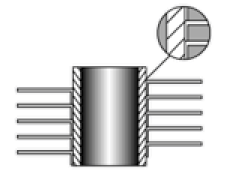

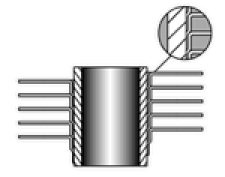

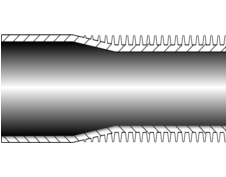

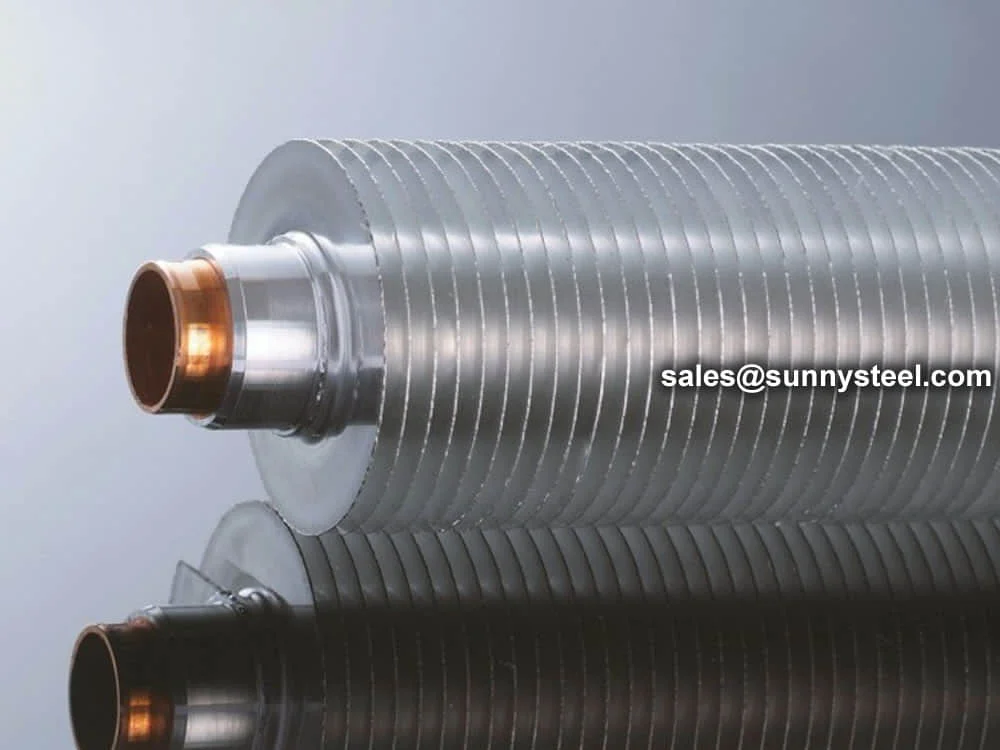

Fin tubes are a type of heat exchanger used in many industries. They are made of aluminum cladded

carbon steel and have brazed aluminum fins. The fins increase the surface area of the tubes,

which allows them to transfer heat more efficiently. This makes them ideal for applications

where high heat transfer rates are required.

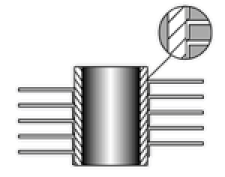

Finned tubes are used in applications that involve the transfer of heat from a hot fluid to a

colder fluid through a tube wall. They are used in condensers, coolers, and furnaces. The larger

surface area means that fewer tubes are needed compared to the use of plain tubes.

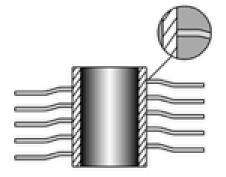

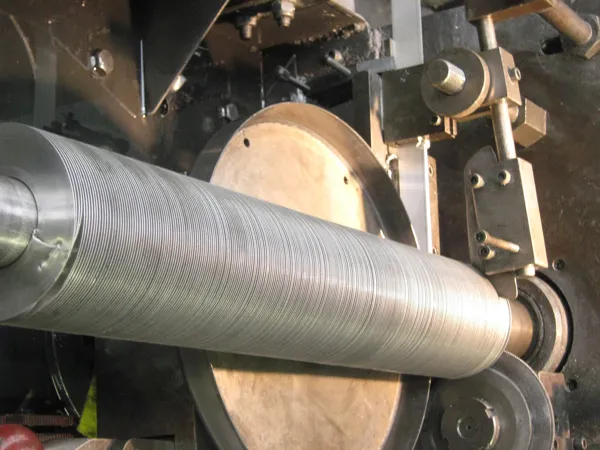

The type of finned tube is chosen depending on the specific requirements of each process

equipment unit. The fin type and combination of materials are chosen based on the specific

requirements of each process equipment unit.

Finned tubes are used in applications where high heat transfer rates are required, such as in

power plants and refrigeration systems. The fins increase the surface area of the tube, allowing

for more efficient heat transfer between two fluids. This makes them an ideal solution for heat

transfer applications where space is limited.

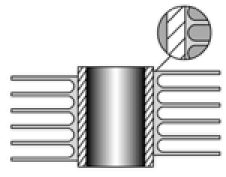

Finned tubes are used in condensers, coolers, and furnaces. The larger surface area means that

fewer tubes are needed compared to the use of plain tubes. This can decrease the overall

equipment size and can in the long-run decrease the cost of the project.

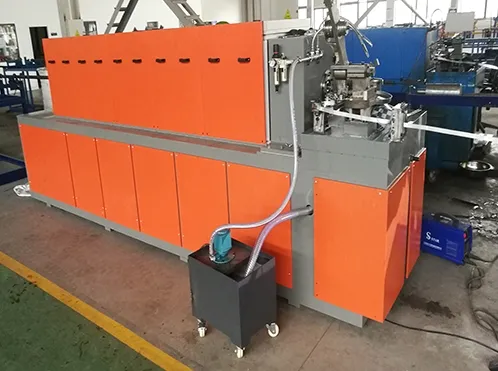

Finned tube heat exchangers can be used in a broad range of industries including oil & gas,

power generation, marine and HVAC&R. They generally use air to cool or heat fluids such as

air, water, oil or gas, or they can be used to capture or recover waste heat.

The biggest problem with using a finned tube heat exchanger is with the cleaning and maintenance

of the outer surface of the tubes. Because of the fins, mechanical cleaning becomes very

difficult and you would have to go for chemical cleaning.