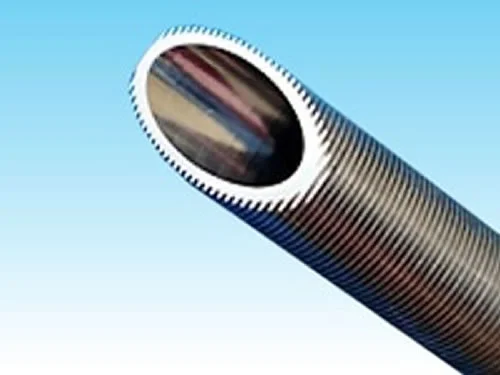

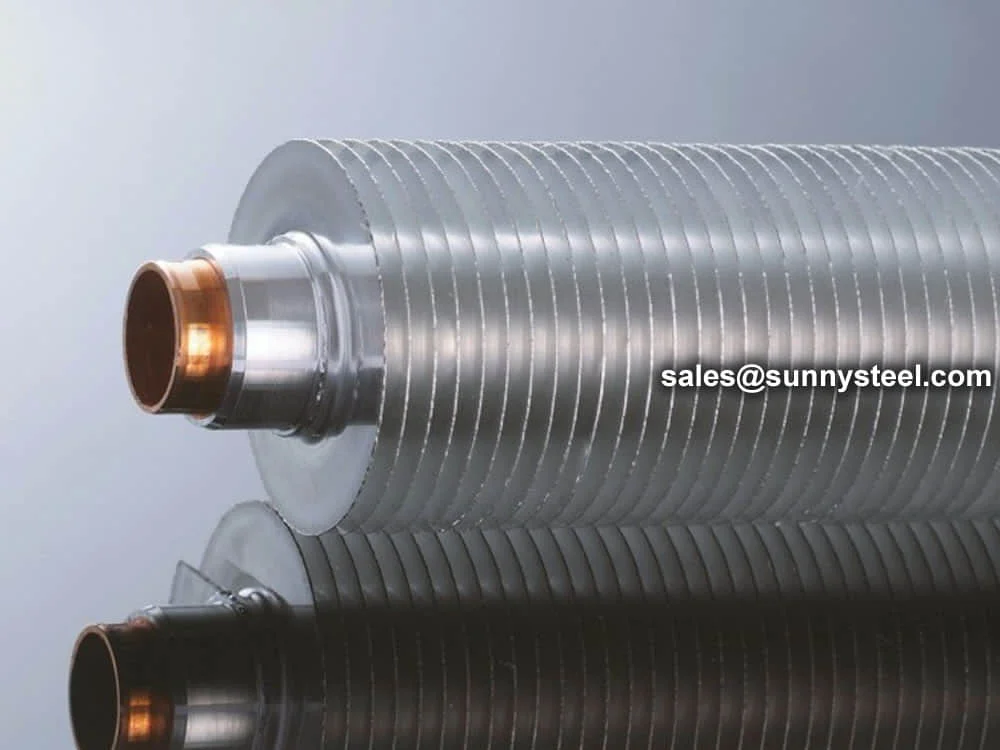

Low Fin Tubes, also referred to as low finned tubes, are seamless

heat exchanger fins designed to optimize thermal transfer by increasing the

external surface area through low-height fins formed directly from the base tube material. These thermal

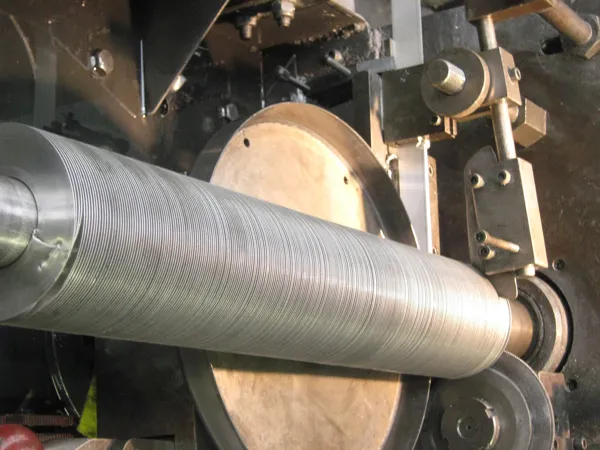

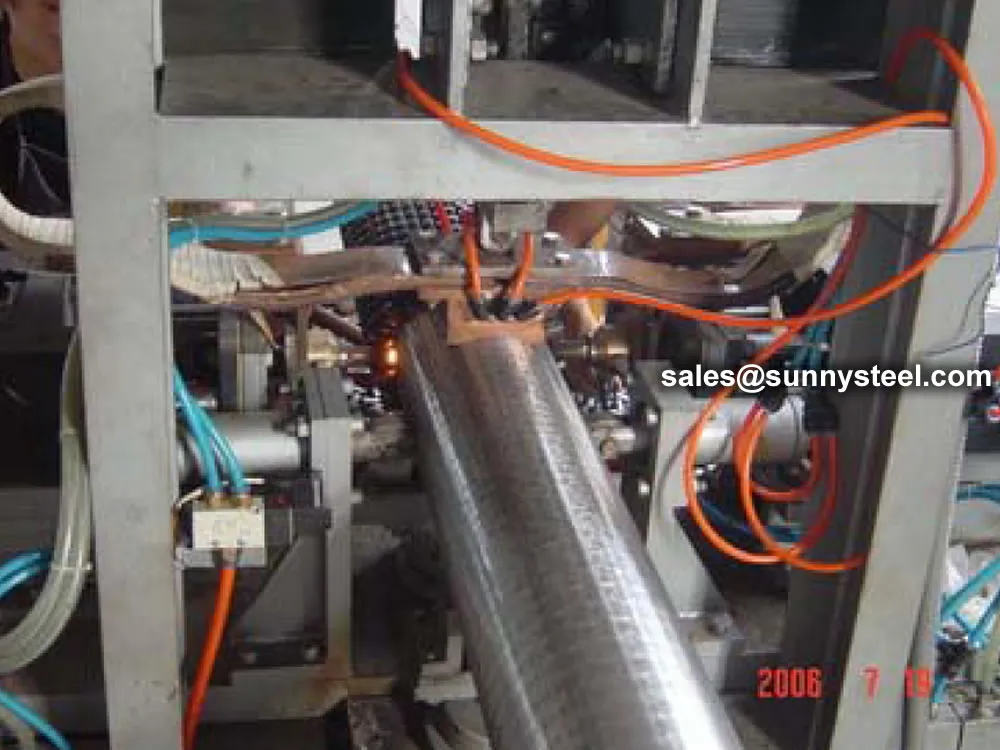

transfer tubes are manufactured using cold rolling or extrusion processes, ensuring a robust, integral

structure without welds or joints. Conforming to standards such as ASTM A179, A213, ASTM B359, and ASME SB338,

low fin tubes are widely used in petrochemical, refrigeration, power generation, and chemical

processing industries, offering excellent corrosion resistance and boiler pipeline

protection in demanding environments.

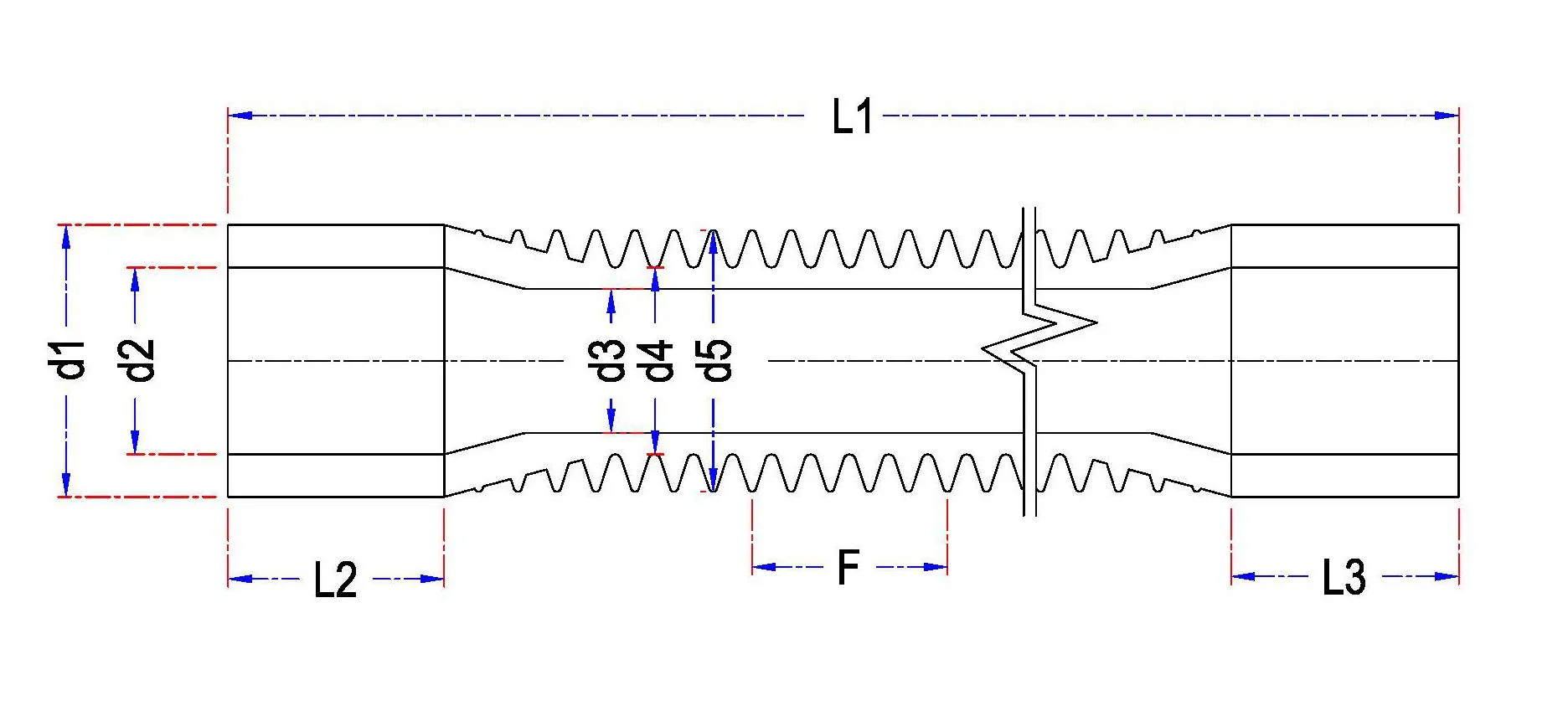

The production process involves rolling or extruding fins from the base tube, creating low fins with heights ranging

from 0.3mm to 1.5mm and fin pitches of 19 to 43 fins per inch (FPI). Base tube outer diameters typically range from

12.7mm to 25.4mm, with customizable lengths up to 25 meters. Materials include carbon steel (A179, A192), stainless

steel (TP304, TP316), copper alloys (C12200, C70600), and titanium (Gr2, Gr12), with optional surface treatments

like galvanization, 3LPE, or epoxy coatings to enhance corrosion resistance. The seamless design

eliminates gaps, ensuring high durability and resistance to thermal cycling and vibration in air cooled

exchangers and shell-and-tube heat exchangers.

Low Fin Tubes undergo stringent testing, including hydrostatic, eddy current, tensile, and

flattening tests, to comply with ASTM A498, A1012, and TEMA standards. Their low-fin geometry increases the external

surface area by 2.5 to 3 times compared to plain tubes, significantly improving heat transfer efficiency while

maintaining low pressure drop. These tubes are ideal for applications where shell-side heat transfer is critical,

such as condensers, evaporators, and oil coolers, with operating temperatures up to 260°C and pressures up to 10

MPa. The smooth fin surfaces reduce fouling, making them suitable for handling viscous fluids or gases with

particulates in industries like refrigeration and petrochemical processing.

Compared to high-fin or welded fin tubes, low finned tubes offer a compact and cost-effective

solution, reducing exchanger size and material costs without compromising performance. Their seamless construction

ensures consistent heat transfer under cyclic thermal loads, making them ideal for retrofitting existing systems or

designing compact heat exchangers. In applications like air conditioning, waste heat recovery, and boiler

economizers, low fin tubes provide reliable performance in corrosive environments, such as seawater

or acidic media, due to their robust material options and protective coatings.

Addressing challenges like pipeline corrosion, thermal inefficiency, and space constraints, low fin

tubes deliver a durable and efficient solution for thermal transfer tubes. Their

ability to enhance heat transfer while minimizing weight and footprint makes them a preferred choice for engineers

seeking high-performance solutions in demanding industrial applications. With superior boiler pipeline

protection, these tubes ensure long-term reliability and energy efficiency in petrochemical,

refrigeration, and power generation systems.

Main Features

- Increased Heat Transfer: External fins greatly enhance heat transfer performance.

- Compact Design: Provides higher performance than plain tubes with smaller equipment size.

- Reduced Material Costs: Requires less material to achieve the same heat transfer capacity.

- Corrosion Resistance: Commonly manufactured from copper or stainless steel to extend service life.

- Increased Efficiency: Operates at higher efficiency and lower cost compared to plain tubes.