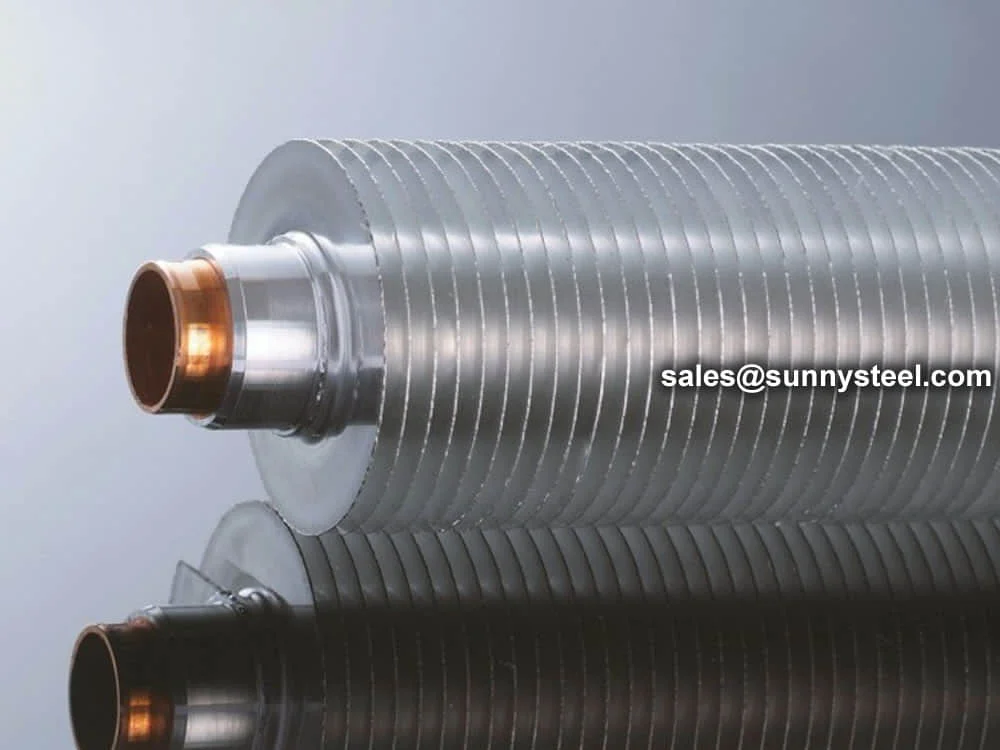

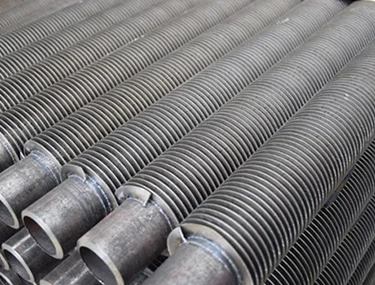

High Fin Tubes, also known as high finned tubes, are advanced heat exchanger fins designed to significantly enhance thermal transfer by incorporating tall fins, typically welded or extruded onto the base tube, to maximize surface area. These thermal transfer tubes are manufactured using high-frequency resistance welding (HFRW) or extrusion processes, ensuring a strong fin-to-tube bond for high-temperature and high-pressure applications. Conforming to standards like ASTM A179, A213, ASME SB338, and TEMA, high fin tubes are widely utilized in petrochemical, power generation, air-cooled heat exchangers, and boiler systems, providing exceptional corrosion resistance and boiler pipeline protection.

The production process involves spirally wrapping or extruding fin strips (commonly aluminum, carbon steel, or stainless steel) onto the base tube, with fin heights ranging from 10mm to 38mm and fin pitches of 2mm to 10mm (100-400 fins per meter). Base tube outer diameters typically range from 19mm to 76mm, with lengths customizable up to 20 meters. Materials include carbon steel (A179, A192), stainless steel (TP304, TP316), copper alloys (C12200), and titanium (Gr2), with surface treatments like galvanization, 3LPE, or epoxy coatings to enhance corrosion resistance. The high fin design increases the external surface area by 5 to 10 times compared to plain tubes, making them ideal for gas-to-liquid or air-to-liquid heat exchange in air cooled exchangers.

High Fin Tubes undergo rigorous testing, including hydrostatic, eddy current, tensile, and thermal performance tests, to ensure compliance with ASTM A450/A450M and TEMA standards. Their tall fins create turbulent airflow, improving the heat transfer coefficient by up to 10 times compared to plain tubes, while maintaining low pressure drop. Suitable for operating temperatures up to 400°C and pressures up to 15 MPa, these tubes excel in applications like air preheaters, waste heat recovery systems, and fired heaters. The robust fin attachment ensures durability in harsh environments, such as those involving seawater, acidic gases, or abrasive particulates.

Compared to low fin tubes, high finned tubes offer greater surface area for enhanced heat transfer, making them ideal for applications requiring maximum thermal efficiency, such as petrochemical refineries and power plant boilers. Variants like serrated or perforated high fins further optimize performance by increasing turbulence and reducing fouling, which is critical for handling dusty or viscous fluids. Their versatility allows for configurations like U-bends or coiled designs, supporting complex system layouts. The ability to use dissimilar materials (e.g., aluminum fins on steel tubes) enhances thermal conductivity while maintaining structural integrity.

Addressing challenges like pipeline corrosion, thermal inefficiency, and fouling, high fin tubes provide a reliable and efficient solution for thermal transfer tubes. Their high surface area and robust construction reduce energy consumption and exchanger size, making them a cost-effective choice for engineers. Whether in air-cooled condensers, boiler economizers, or chemical processing systems, these tubes deliver superior performance, ensuring long-term boiler pipeline protection and operational efficiency in demanding industrial environments.

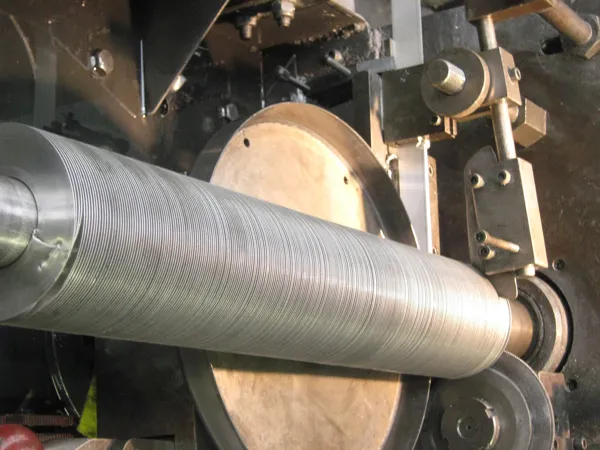

High finned tubes are also called extruded tubes. The finning is achieved by extruding the fin from the tube.

This method of construction is very different from cutting grooves onto the tube as is often done by people who are on the lookout for a shortcut or who don’t know any better.

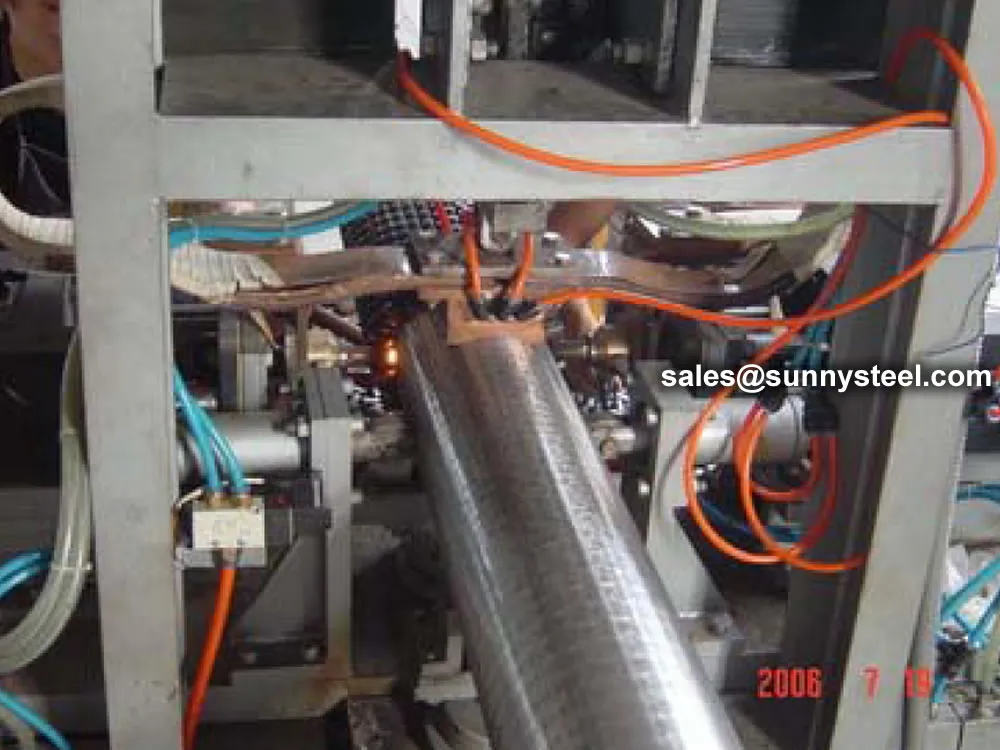

A High fin tube is formed by passing a tube through a set of rollers that form the fins from the parent material of the tube by making it flow in the desired way.

High finned tubes basically consist of a metal tube, surrounded by an aluminum strip or sometimes copper strip. This strip can be applied in different ways. A distinction is made, among others, between a type L, a type KL, a type LL, a type G (= embedded) or a type extruded. With extruded finning the fins are produced our of an aluminium tube instead of aluminium strip. The metal tube can be made of different types of metal, depending on the intended application of the high finned tubes. Within a heat exchanger, the hot medium runs through the finned tubes and heats the tube and the aluminium fins. The metal tube heats up, after which it transfers its heat to the aluminum fins. These fins then ensure that the heat is transferred into the ambient air.

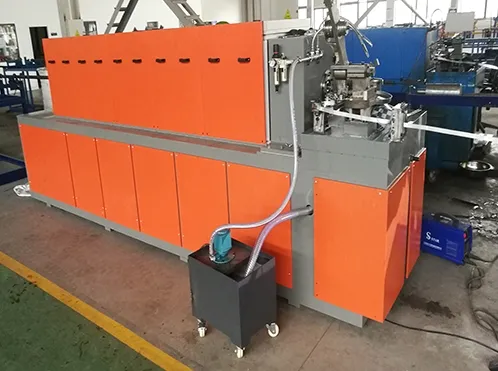

High finned tubes of high quality

After a first small batch of high finned tubes has been produced, we perform a quality check. Where necessary, we adjust the settings of the machines in order to improve the quality of the end product. Even after the last high finned tube rolls off the conveyor belt, we check the quality of the parts. Only when it meets our high standards, we proceed to pack the high finned tubes in special racks and wooden cases. This prevents the parts from being damaged during transport.

What is the difference between high fin and low fin tubes?

High fin tubes are better for applications where the temperature difference between two fluids is high. Low fin tubes are better for applications where the temperature difference is low.

High fin tubes are made of a metal tube surrounded by an aluminum or copper strip. The strip can be applied in different ways, including type L, type KL, type LL, type G (embedded), or type extruded. The higher the fin height, the more surface area and heat transfer capabilities.

Low fin tubes are made of a single material and have a smaller fin of about 1/16th of an inch. They are generally used in liquid to liquid or liquid to gas applications such as coolers, condensers, and chillers.

The profile of the fins has a significant effect on the performance of a finned tube heat exchanger. The larger the fins and the tighter the fin pitch, the more thermal conductivity is achieved.