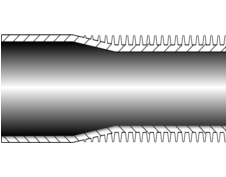

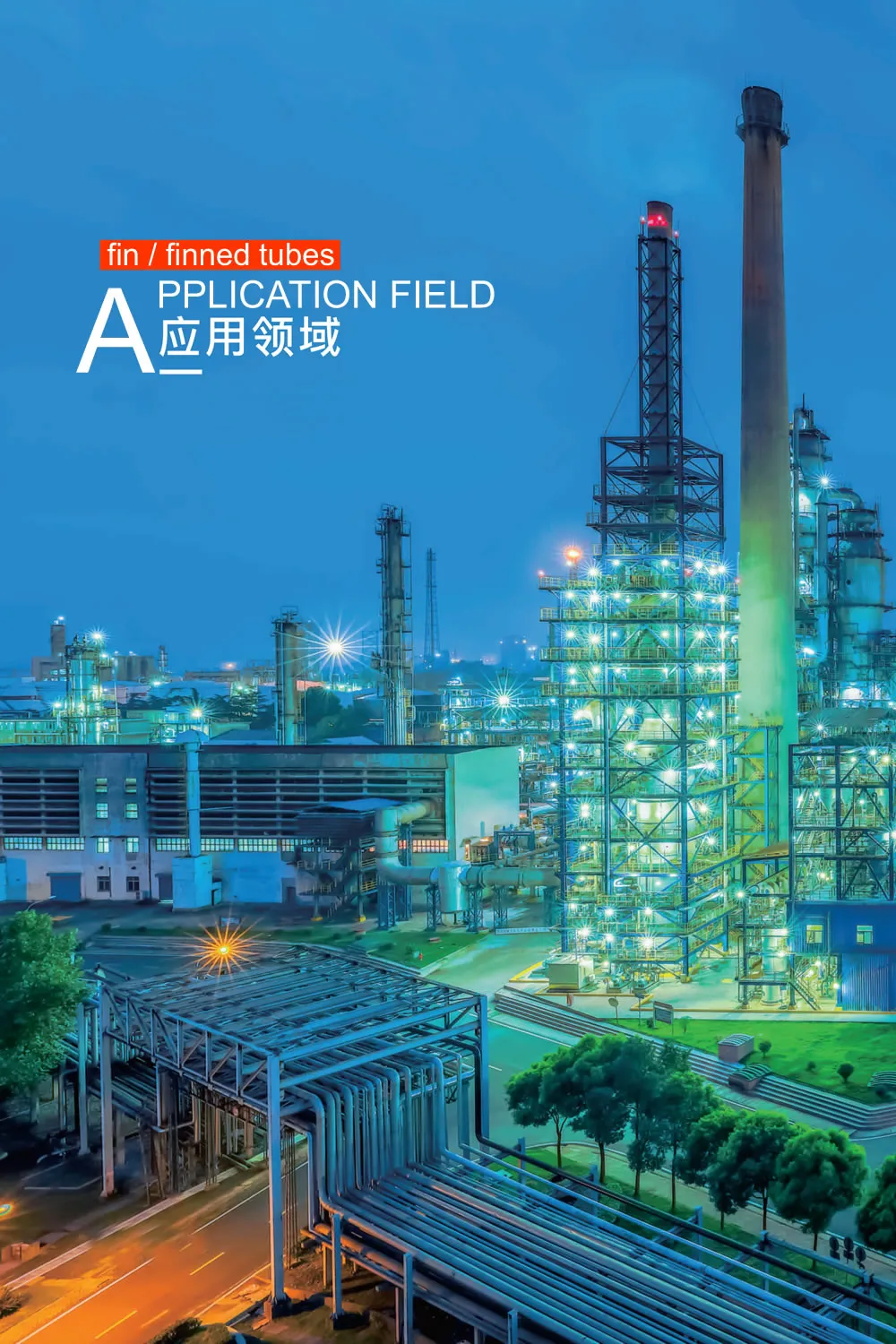

Stainless Steel Fin Tube, also referred to as finned stainless tubes, is a premium heat exchanger fin engineered to maximize thermal transfer by incorporating extended fins on a stainless steel base tube. Constructed from high-grade stainless steel grades like 304, 316, or 316L, these corrosion resistant fin tubes offer exceptional resistance to oxidation, pitting, and chloride-induced corrosion. Compliant with standards such as ASTM A179, A213, A269, and ASME SB338, stainless steel finned tubing is widely utilized in petrochemical refineries, power generation plants, HVAC systems, and refrigeration units, ensuring reliable boiler pipeline protection in demanding environments with temperatures up to 800°F (427°C).

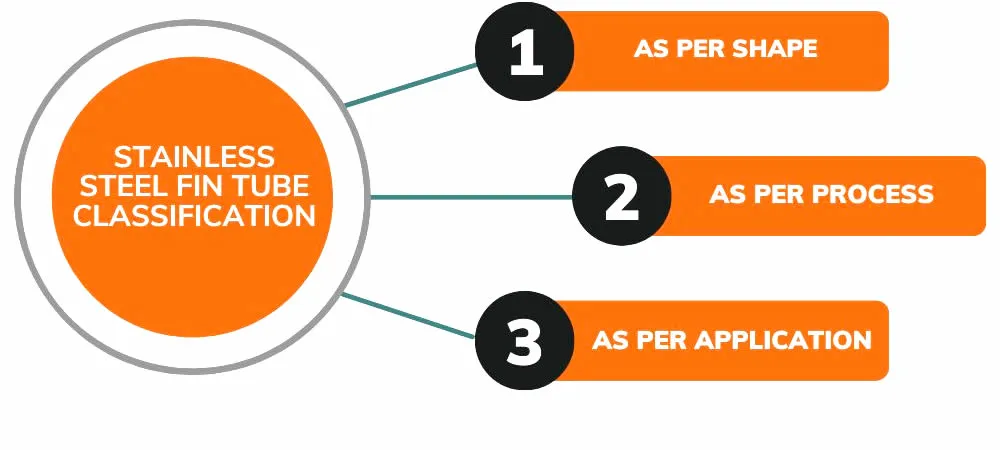

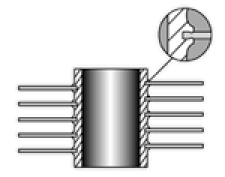

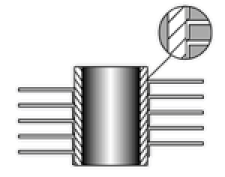

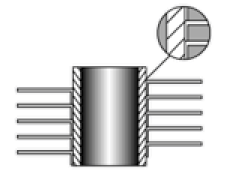

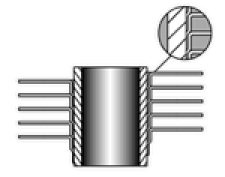

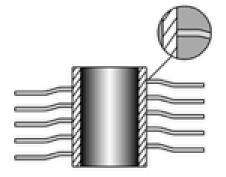

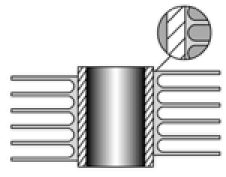

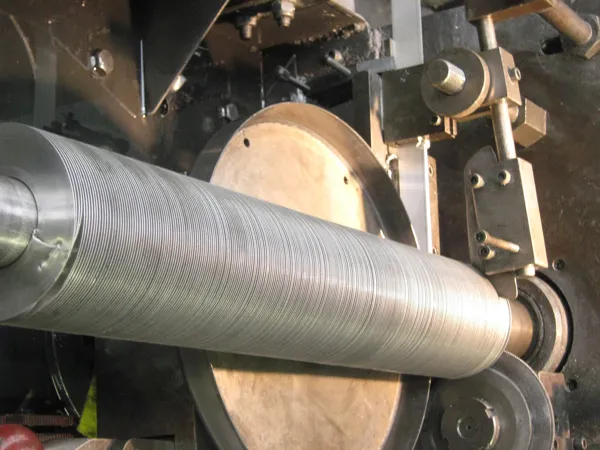

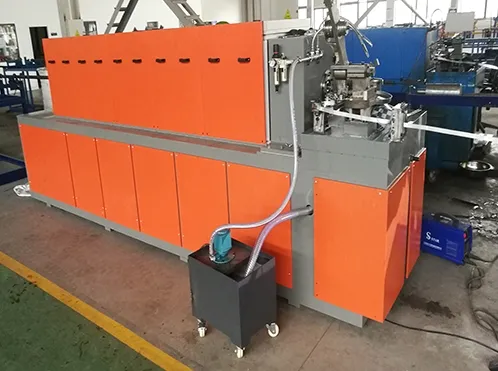

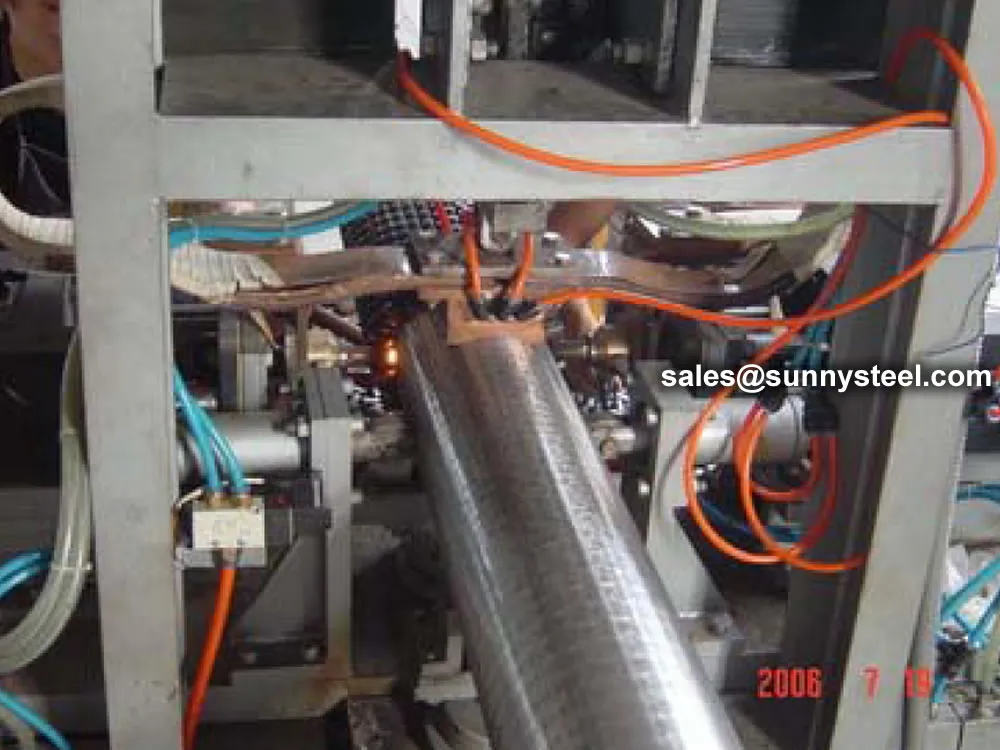

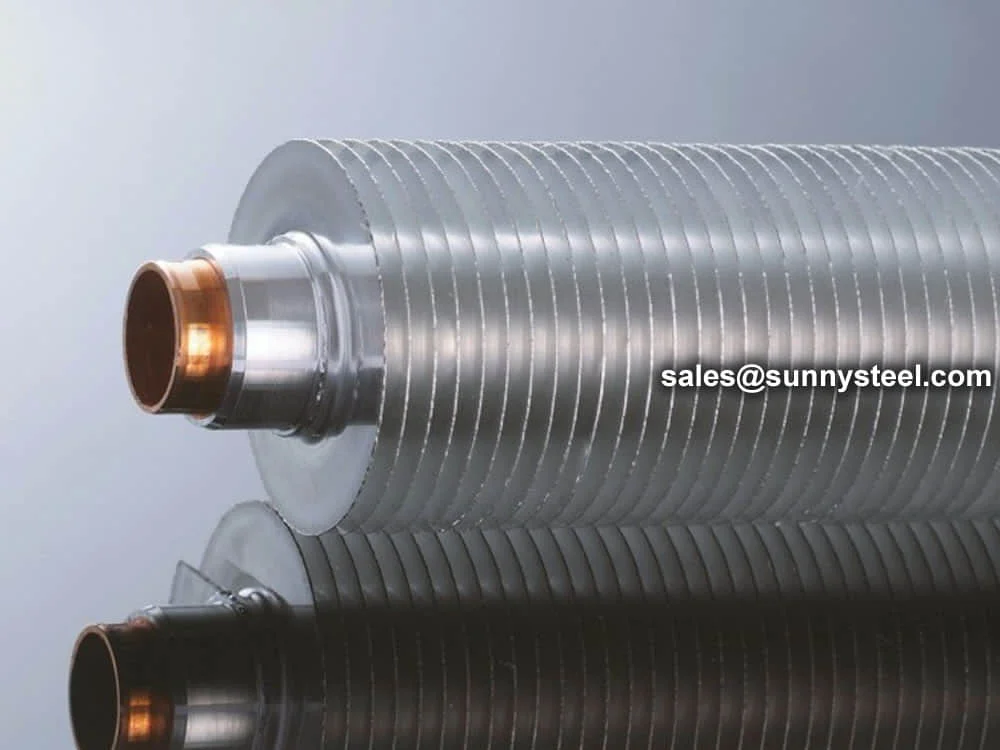

The manufacturing process involves attaching fins to the base tube through methods like high-frequency welding, laser welding, extrusion, or tension wrapping. Fin configurations include low-fin, L-fin, embedded G-fin, or spiral fins, tailored to specific application needs. Base tube outer diameters range from 12.7mm to 50.8mm (1/2" to 2"), with fin heights of 0.3mm to 16mm, fin thicknesses of 0.4mm to 0.6mm, and fin pitches of 19 to 43 fins per inch (FPI). Tube lengths can be customized up to 25 meters, with surface treatments such as pickling, passivation, or 3LPE coatings to enhance corrosion resistance against harsh conditions like acidic gases or saline environments.

Finned stainless tubes undergo stringent testing, including hydrostatic, tensile, flattening, and eddy current tests, to meet ASTM A450/A450M and TEMA standards. The finned design increases the external surface area by 2.5 to 10 times compared to plain tubes, significantly improving heat transfer efficiency for gas-to-liquid or liquid-to-air applications. These tubes excel in handling corrosive fluids, such as deionized water or high-purity coolants, making them ideal for industries like chemical processing, marine, and food processing. They withstand pressures up to 10 MPa and resist fouling from ash or soot in high-fouling environments like coal-fired power plants.

Compared to carbon steel or aluminum-finned tubes, stainless steel fin tubes provide superior durability in corrosive conditions, such as offshore platforms or desalination plants. Variants with copper fins on stainless steel tubes enhance thermal conductivity while maintaining corrosion resistance, achieving cooling capacities of 380 to 3,000 W. The seamless or welded construction ensures leak-free performance, and the tubes’ biocompatibility supports applications in medical imaging, semiconductor equipment, and analytical instrumentation. Custom configurations, including U-bends or coiled designs, integrate seamlessly into complex air cooled exchangers.

Addressing challenges like pipeline corrosion, thermal inefficiency, and high maintenance costs, stainless steel fin tube offers a robust solution for thermal transfer tubes. Its high-strength properties, corrosion resistance, and efficient finned design reduce energy consumption and equipment size, making it a cost-effective choice for engineers. Whether in power electronics, HVAC systems, or petrochemical furnaces, these tubes deliver exceptional performance, safety, and longevity, ensuring reliable boiler pipeline protection in diverse industrial applications.