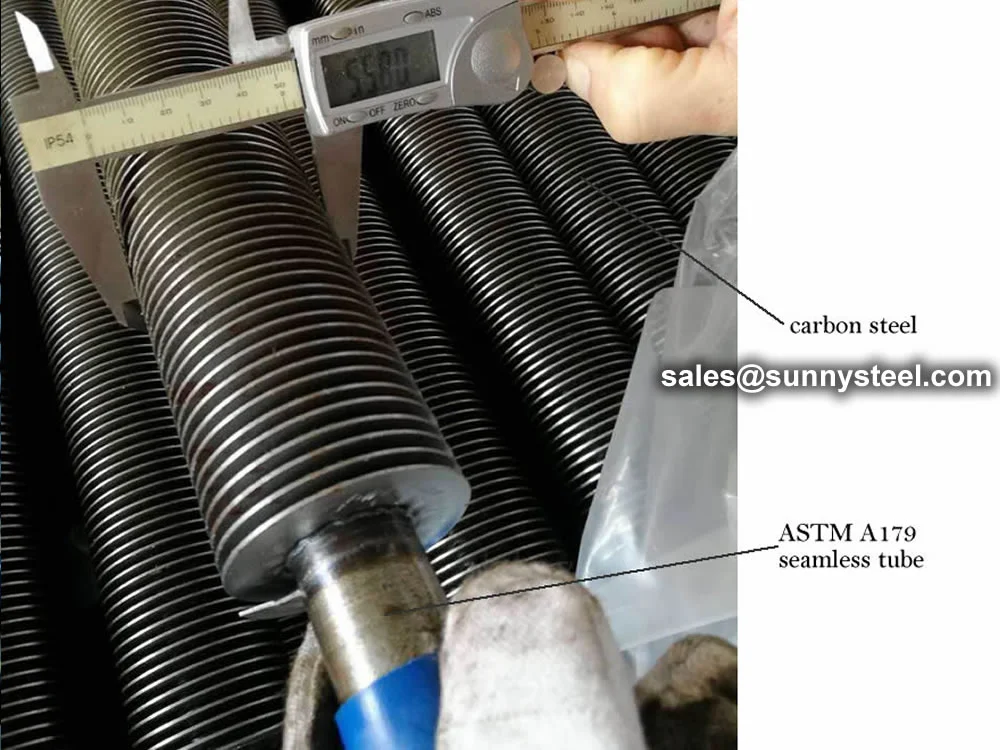

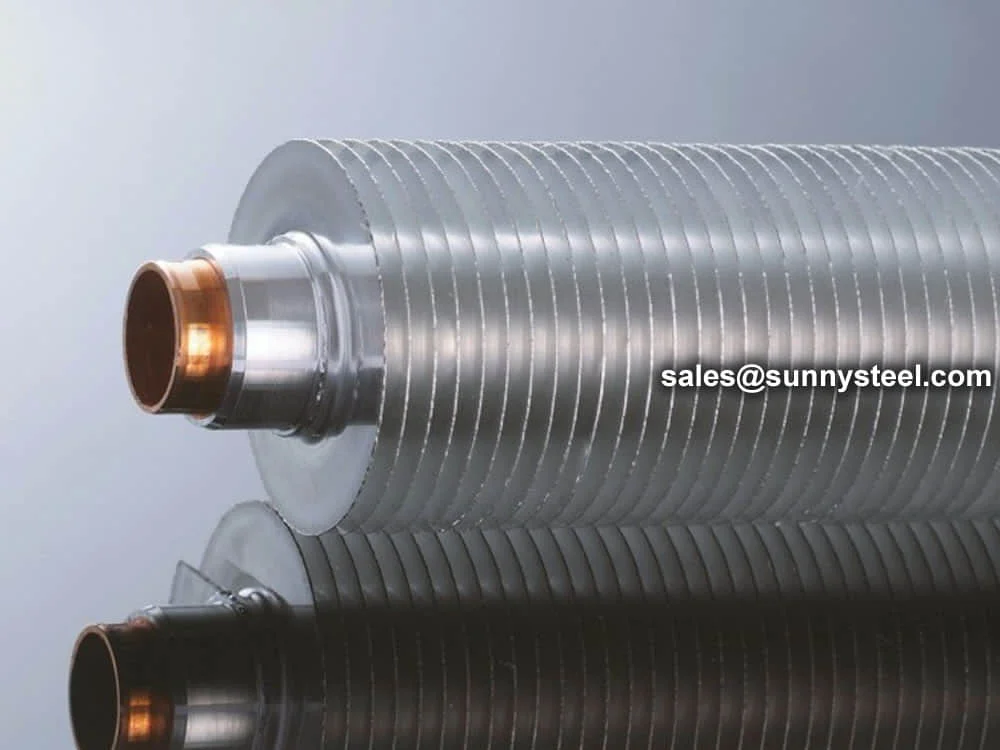

ASTM A179 Fin Tubes, also known as seamless finned tubes, are high-performance heat exchanger fins crafted from seamless cold-drawn low-carbon steel, designed to maximize thermal transfer by adding fins to increase surface area. Conforming to ASTM A179/ASME SA179 standards, these low-carbon fin tubes offer excellent corrosion resistance and are widely used in tubular heat exchangers, condensers, and similar heat transfer equipment in petrochemical, power generation, and HVAC industries. They provide reliable boiler pipeline protection in applications with temperatures up to 350°C and pressures up to 10 MPa.

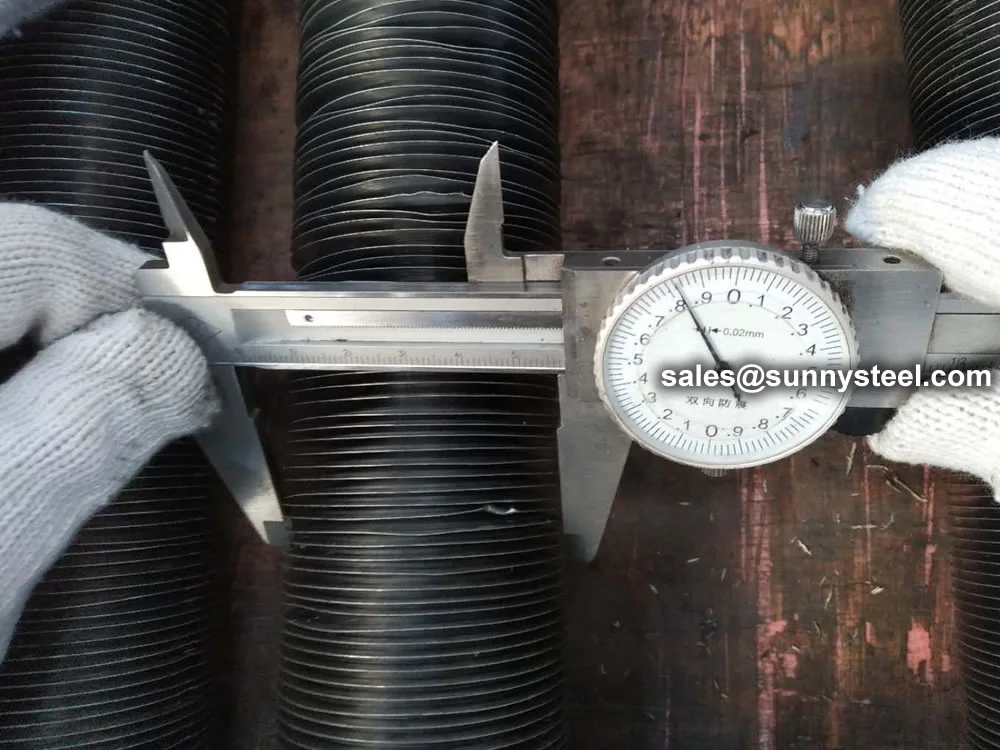

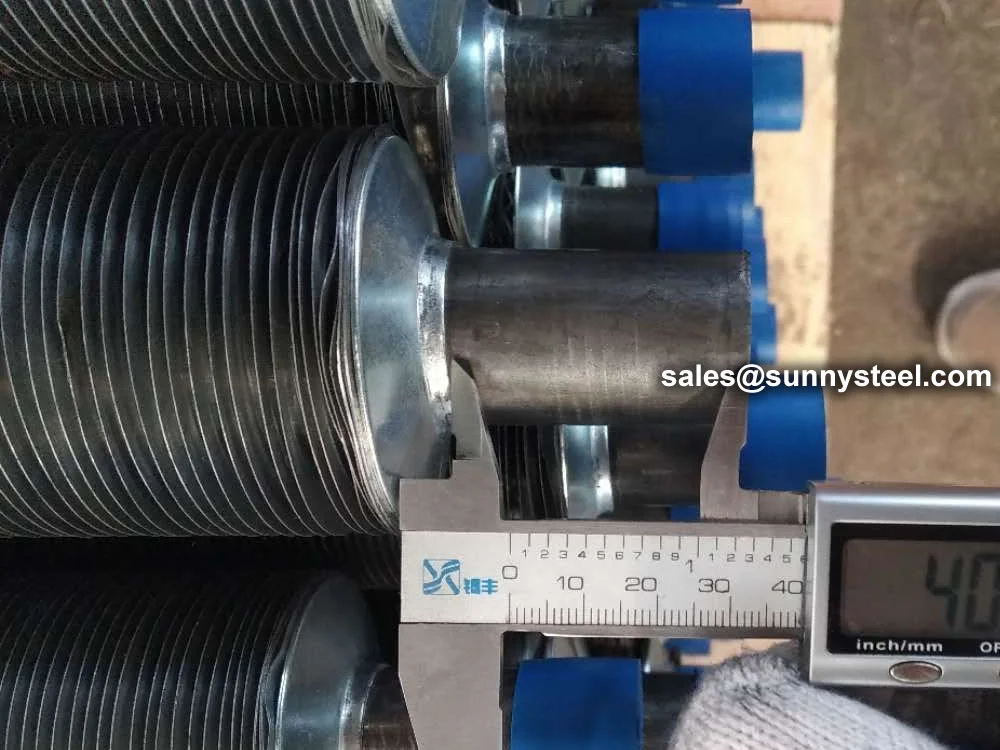

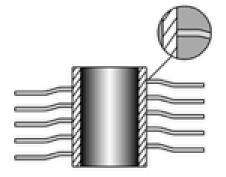

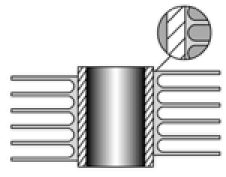

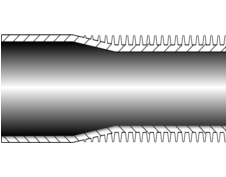

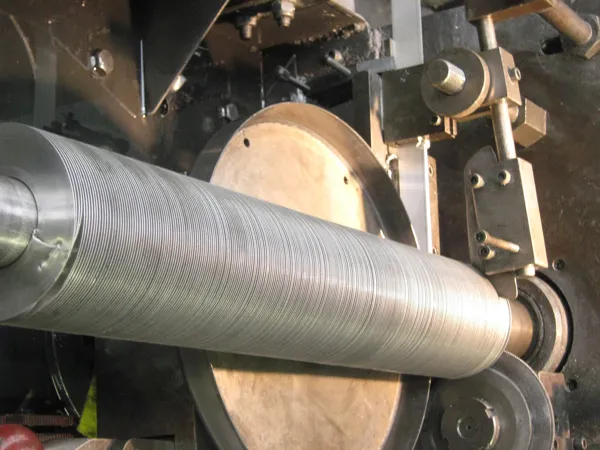

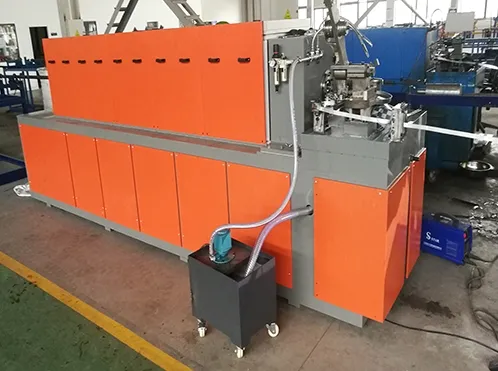

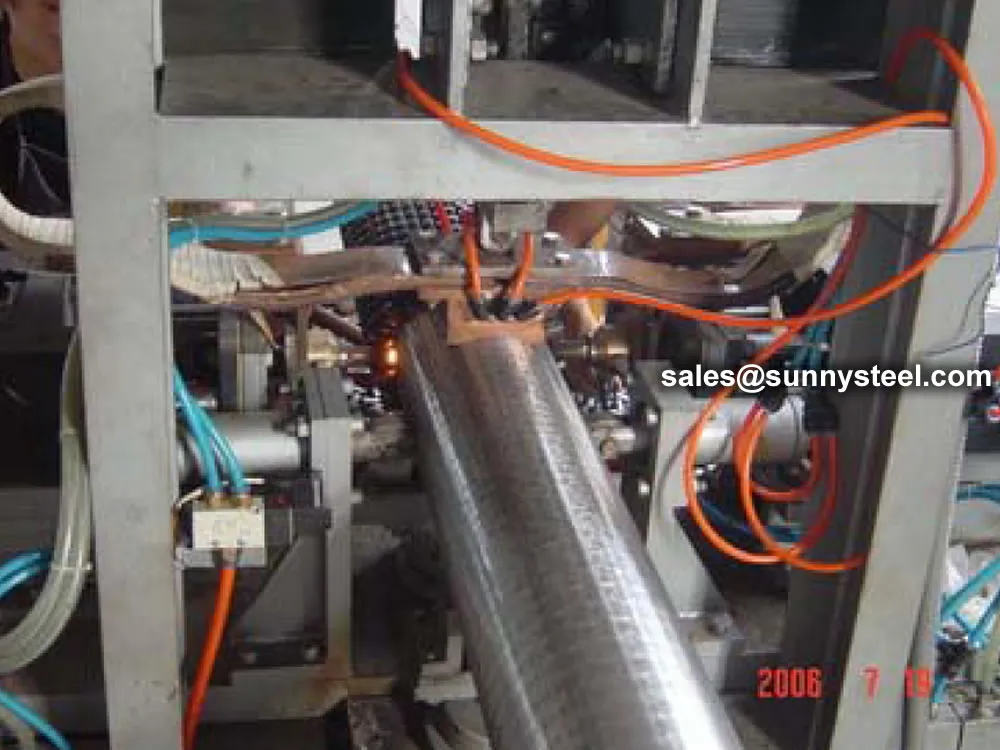

The manufacturing process involves cold-drawing seamless low-carbon steel tubes, followed by fin attachment through methods like L-type, LL-type, KL-type, G-type (embedded), or extruded finning. Fin types are selected based on application needs, with outer diameters ranging from 3.2mm to 76.2mm (1/8" to 3"), fin heights of 0.3mm to 16.5mm, fin thicknesses of 0.4mm to 2mm, and fin pitches as low as 2.1mm (12 FPI). Tubes can be customized up to 18 meters in length, with surface treatments like zinc or aluminum metallization enhancing corrosion resistance against atmospheric conditions. The seamless construction ensures no weld repairs, and tubes are heat-treated at 1200°F (650°C) or higher post-cold drawing to optimize mechanical properties.

ASTM A179 Fin Tubes undergo rigorous testing, including tensile, flattening, hardness, and hydrostatic tests, to comply with ASTM A450/A450M and TEMA standards. The finned design increases the external surface area by 2.5 to 10 times compared to plain tubes, significantly improving heat transfer efficiency in liquid-to-gas or gas-to-liquid applications. These tubes are ideal for handling non-corrosive fluids in condensers, air coolers, and economizers, with their low-carbon composition (0.06-0.18% C) ensuring good weldability and formability. The fins promote turbulence, reducing fouling from ash or soot in high-fouling environments like coal-fired power plants.

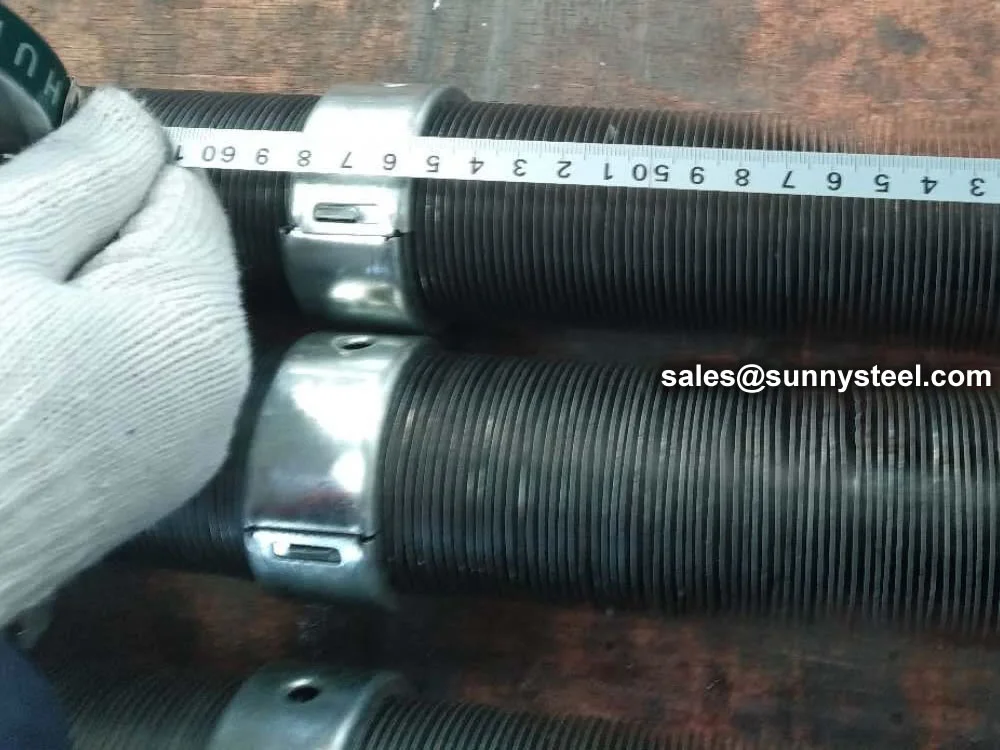

Compared to stainless steel or alloy fin tubes, low-carbon fin tubes are more cost-effective for applications with moderate corrosion risks, such as water-based cooling systems or low-pressure steam systems. Available fin types include L-type for cost-effective performance, embedded G-type for high-temperature stability, and extruded types for enhanced durability. Accessories like tube support boxes or clamps (aluminum, zinc, or stainless steel) ensure stability in air cooled exchangers. The tubes’ versatility supports U-bend or straight configurations, meeting diverse project requirements in industries like food processing and chemical manufacturing.

Addressing challenges like pipeline wear, thermal inefficiency, and moderate corrosion, ASTM A179 Fin Tubes provide a robust solution for thermal transfer tubes. Their seamless construction, high efficiency, and cost-effective design make them a preferred choice for engineers seeking reliable boiler pipeline protection in demanding industrial settings. Whether in power plant condensers, petrochemical air coolers, or HVAC radiators, these tubes deliver exceptional performance, energy savings, and longevity.

General Requirements

Standards and quality requirements for Stainless Steel Low Finned Tubes

- Tube material shall comply with ASME II-A (latest edition).

- Fin material shall comply with ASME II-B (latest edition).

- Certification required according to EN 10204 3.1 [2004].

- Tubes must conform to ASME-II SA 450.

- Seamless tubes only. Tube surface shall be free from repair welds, imperfections, scale, or rust.

- A light rust protection product may be acceptable. No weld repair is permitted.

- Materials must be adequately protected to avoid damage to fins and tubes during shipping and handling.

- Tubes shall be cut square and deburred on both I.D. and O.D.

- Tubes must be supplied with zinc separator protection during packaging.

ASTM A179 Galvanized Carbon Steel Finned Tubeh3or Cooler

ASTM A179 Galvanized Carbon Steel Finned Tube for Cooler is a high-efficiency heat exchanger finned tube made from seamless cold-drawn low-carbon steel, featuring galvanized fins to enhance thermal transfer and corrosion resistance. Conforming to ASTM A179/ASME SA179 standards, these seamless finned tubes are engineered for tubular heat exchangers, condensers, coolers, and similar apparatus in petrochemical, power generation, and HVAC industries. The galvanization process applies a zinc coating to the fins, providing robust protection against atmospheric corrosion and extending service life in harsh environments up to 350°C.

The manufacturing process begins with seamless cold-drawing of low-carbon steel tubes, followed by fin attachment methods such as L-type, G-type embedded, or spiral winding, and hot-dip galvanization for the fins to ensure uniform zinc coverage. Base tube outer diameters range from 3.2mm to 76.2mm (1/8" to 3"), with wall thicknesses from 0.4mm to 14mm, fin heights of 0.3mm to 16.5mm, and fin pitches as low as 2.1mm (12 FPI). Tubes are heat-treated at 1200°F (650°C) or higher post-cold drawing to achieve optimal mechanical properties, and lengths can be customized up to 18 meters with plain or beveled ends for easy installation.

ASTM A179 Galvanized Carbon Steel Finned Tubes undergo comprehensive testing, including tensile, flattening, hardness, flaring, and hydrostatic tests, to meet ASTM A450/A450M and TEMA standards. The finned design increases the external surface area by 2.5 to 10 times compared to plain tubes, significantly improving heat transfer efficiency in liquid-to-gas or gas-to-liquid applications. The galvanized coating provides sacrificial protection, preventing rust in humid or mildly corrosive conditions, making these tubes ideal for coolers handling non-corrosive fluids like water or low-pressure steam. Their seamless construction ensures no weld repairs, enhancing reliability under pressures up to 10 MPa.

Compared to stainless steel fin tubes, galvanized finned tubes offer a cost-effective alternative for moderate corrosion environments, while providing similar thermal performance. The low-carbon composition (0.06-0.18% C) ensures good weldability and formability, allowing for U-bend or coiled configurations in compact air cooled exchangers. Accessories like aluminum support boxes or clamps further ensure stability. These tubes are particularly suited for applications in power plant condensers, petrochemical air coolers, and HVAC radiators, where their galvanized fins resist fouling from ash or soot.

Addressing challenges like pipeline corrosion, thermal inefficiency, and cost constraints, ASTM A179 Galvanized Carbon Steel Finned Tubes for Cooler deliver a durable solution for thermal transfer tubes. Their seamless, galvanized construction ensures long-term boiler pipeline protection, making them a preferred choice for engineers in demanding industrial settings. Whether in waste heat recovery or process cooling systems, these tubes provide reliable performance, energy savings, and extended service life.