ASTM A192 Fin Tubes, also known as seamless finned tubes, are

high-performance boiler finned tubes made from seamless carbon steel, specifically engineered for

high-pressure service in heat exchanger finned tubes. Conforming to ASTM A192/ASME SA192 standards,

these carbon steel fin tubes are designed for superheaters, water wall panels, heat exchangers, and

condensers in petrochemical plants, power generation facilities, and general engineering applications. With their

seamless construction and optional fin attachments, ASTM A192 fin tubes provide superior

thermal transfer efficiency and corrosion resistance, ensuring robust

boiler pipeline protection in demanding environments up to 650°C.

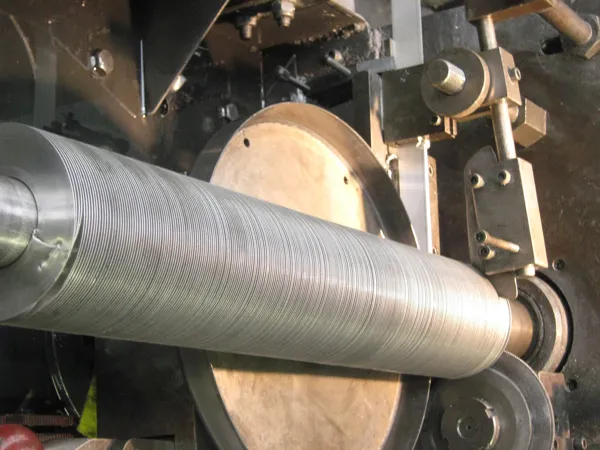

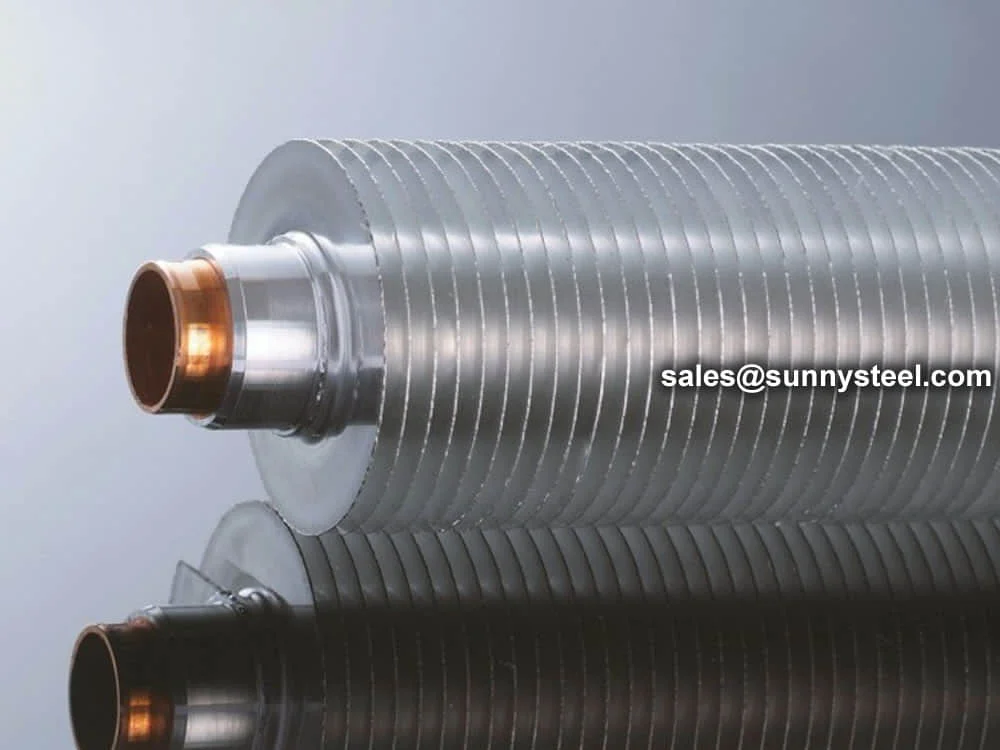

The manufacturing process involves hot-rolling or cold-drawing seamless low-carbon steel tubes, followed by fin

attachment methods such as L-type wrapping, G-type embedding, or extruded finning to increase surface area. Base

tube outer diameters range from 1/2 in. to 7 in. (12.7mm to 177.8mm), with wall thicknesses from 0.085 in. to 1.000

in. (2.2mm to 25.4mm), and fin configurations customizable for specific heat transfer needs. Tubes are heat-treated

at 1200°F (650°C) or higher after cold-finishing to optimize mechanical properties, with lengths up to 18 meters and

ends protected by varnishing or metallization for enhanced corrosion resistance. This seamless

carbon steel fin tubes design minimizes leak risks and supports bending, flanging, and welding for

versatile installations.

ASTM A192 Fin Tubes are subjected to rigorous testing, including tensile, flattening, hardness,

flaring, and hydrostatic tests, to comply with ASTM A450/A450M and TEMA standards. The finned structure boosts

external surface area by 2.5 to 10 times compared to plain tubes, significantly improving heat transfer in

gas-to-liquid or liquid-to-gas applications. These tubes are ideal for high-pressure boilers (up to 9.8 MPa),

superheaters, and economizers, where their low-carbon composition ensures good weldability and formability. The fins

promote turbulence, reducing fouling from ash or particulates in high-fouling environments like coal-fired power

plants, while optional coatings like 3LPE provide additional protection against atmospheric corrosion.

Compared to stainless steel or alloy fin tubes, ASTM A192 fin tubes offer a cost-effective solution

for moderate-corrosion applications, with similar thermal performance but lower material costs. Available fin types

include L-type for economical designs, embedded G-type for high-temperature stability, and extruded types for

enhanced durability. Accessories like support boxes or clamps ensure stability in air cooled

exchangers. These seamless finned tubes are particularly suited for refineries, marine

applications, paper pulping, and pressure vessels, where their seamless construction and high-pressure capability

ensure reliability under extreme conditions.

Addressing challenges like pipeline wear, thermal inefficiency, and moderate corrosion, ASTM A192 Fin

Tubes deliver a durable solution for thermal transfer tubes. Their seamless, finned

design ensures long-term boiler pipeline protection, making them a preferred choice for engineers

in demanding industrial settings. Whether in power plant superheaters, petrochemical heat exchangers, or general

engineering systems, these tubes provide reliable performance, energy savings, and extended service life.

Finned Tubes for Enhanced Heat Transfer

ASTM A192 seamless carbon steel finned tubes designed for high pressure and high temperature heat exchanger applications.

High Heat Transfer

Fins enlarge the effective surface area, improving heat exchange efficiency in demanding environments.

High-Pressure Resistance

Manufactured from seamless carbon steel to withstand pressures up to 9.8 MPa, ensuring durability and reliability.

Temperature Tolerance

Ideal for high-temperature boiler, superheater, and heat recovery applications in power and process industries.

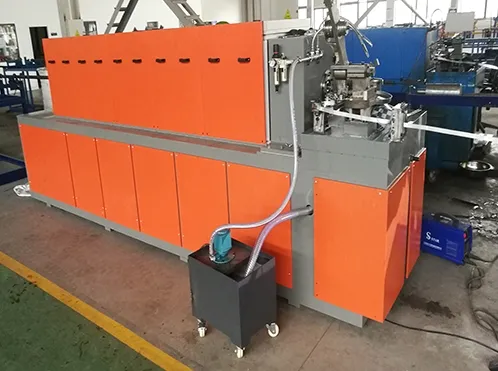

Manufacturing Methods

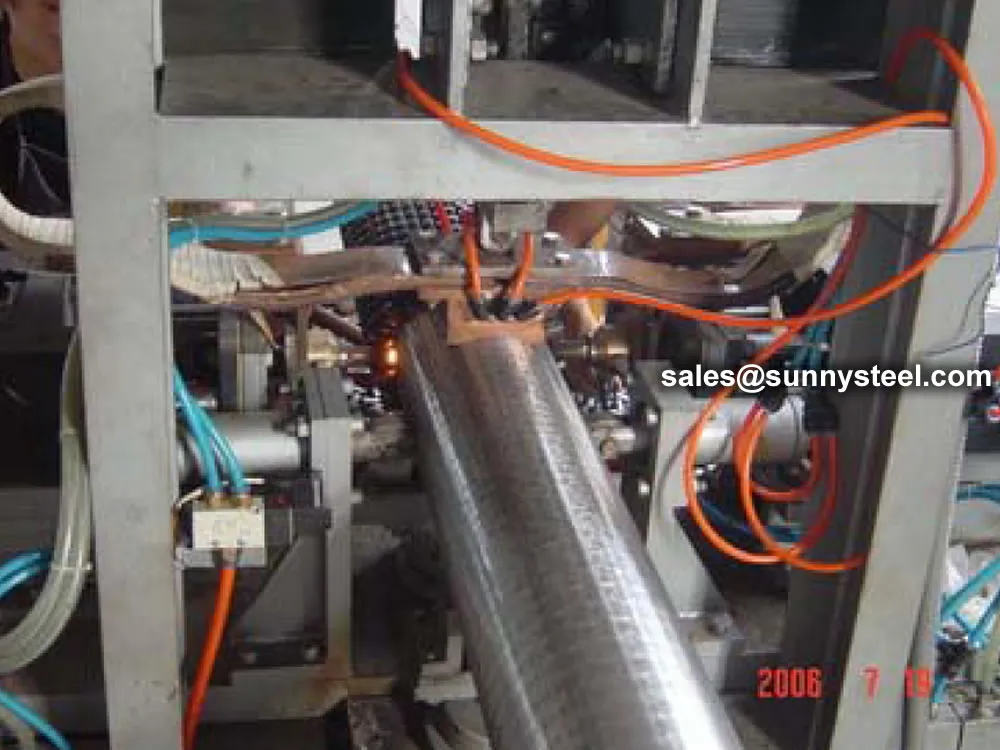

Resistance Welding

Longitudinal fins welded along the tube length for extended surface area.

High-Frequency Welding

Helical fins continuously welded with high-frequency resistance for strength and durability.

Embedded Fin Method

Aluminum or copper strips wound into grooves on the tube surface for excellent thermal conductivity.