What is a Coupling?

A coupling is a mechanical device used to connect two shafts together at their ends

for the purpose of transmitting power. They are essential in various industrial and mechanical

systems to ensure efficient and reliable power transmission.

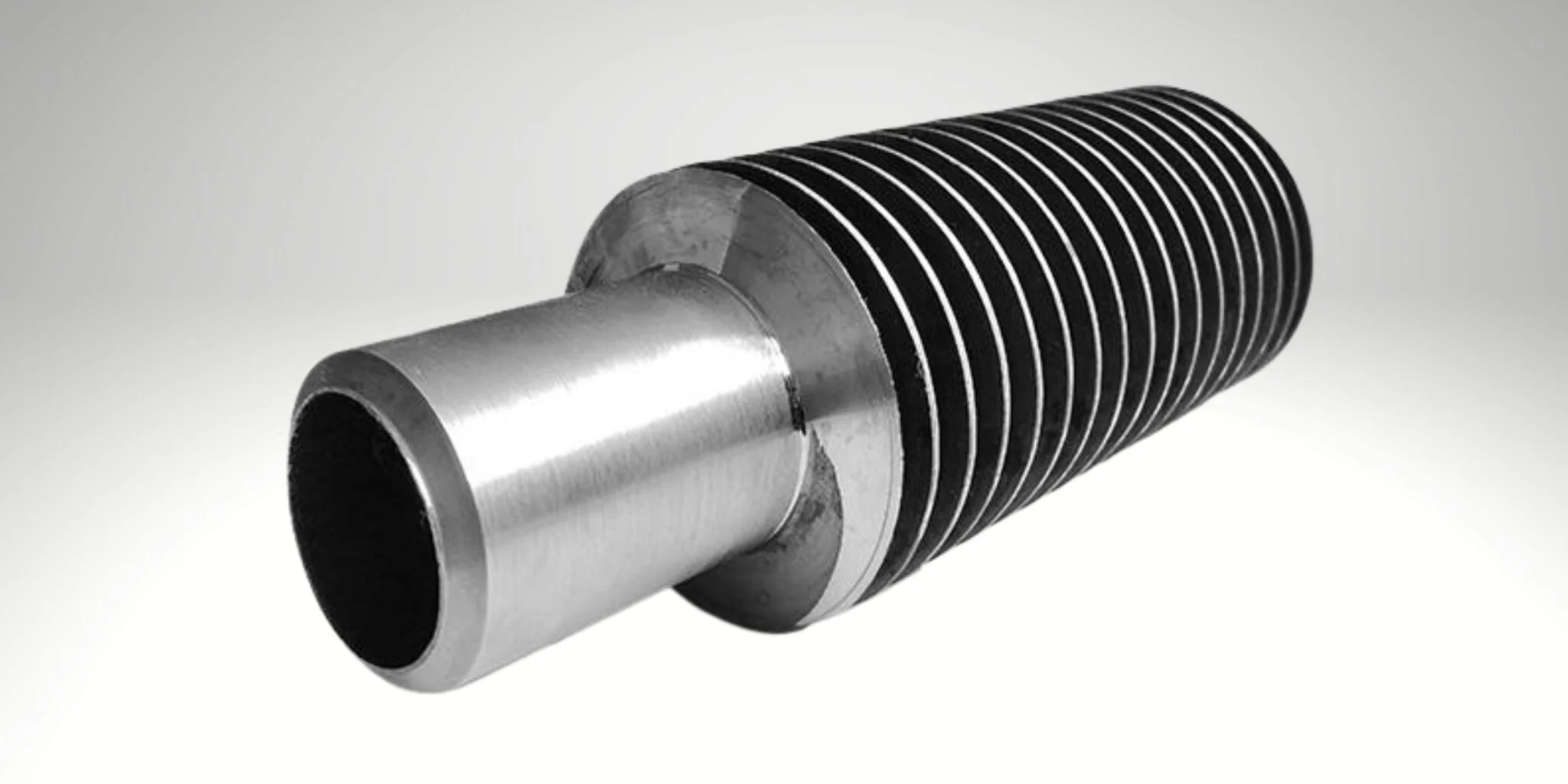

Coupling for Piping Systems is a fundamental pipe fitting used to connect two

pipes or tubes of the same or different diameters, ensuring a secure, leak-free joint in various industrial

and mechanical applications. These piping system couplings are essential for transmitting

fluids, gases, or power efficiently, with types like full couplings, half couplings, and reducing couplings

tailored for specific needs. Conforming to standards such as ASTM A105, ASME B16.11, and API 5L,

pipe couplings are manufactured from materials like carbon steel, stainless steel, or

ductile iron, offering excellent corrosion resistance and strength for use in water supply,

drainage, petrochemical pipelines, and mechanical systems.

The manufacturing process involves forging, casting, or machining the coupling body, followed by threading

(NPT or BSPT) or socket welding for seamless connections. Full couplings connect two pipes

of the same size with internal threads on both ends, while half couplings have one threaded

end and one socket weld end for branching or repairs. Reducing couplings join pipes of

different diameters, facilitating transitions in piping layouts. Available in sizes from 1/8" to 8" (DN6 to

DN200), with pressure ratings up to Class 6000, these fittings are customizable for lengths up to 300mm and

surface treatments like galvanization or epoxy coating to enhance corrosion resistance in

harsh environments such as acidic or saline conditions.

Coupling for Piping Systems undergoes rigorous testing, including hydrostatic, tensile, and

non-destructive tests, to ensure compliance with ASME B16.11 and API standards. Their threaded or welded

designs prevent leaks and accommodate misalignment, making them ideal for applications requiring frequent

disassembly or repairs. In petrochemical pipelines, full couplings ensure reliable fluid

flow, while reducing couplings adapt to varying pipe sizes in complex systems. The ductile

iron or stainless steel construction provides high mechanical strength, with pressure capabilities up to

6000 PSI, suitable for high-pressure water treatment or oil and gas transmission.

Compared to flanges or unions, piping system couplings offer a compact, cost-effective

solution for straight pipe connections, with socket weld types providing strength comparable to butt welds

without the need for beveling. They are particularly advantageous in repair scenarios, as half

couplings allow quick fixes without disturbing the entire line. For dissimilar materials, brass

or stainless variants prevent galvanic corrosion, ensuring longevity in mixed-metal systems. These fittings

support various end connections, including threaded, socket weld, or plain end, and are often used in

conjunction with adapters for flexible installations in mechanical or plumbing systems.

Addressing challenges like leaks, misalignment, and corrosion in industrial piping, pipe

couplings provide a versatile and durable solution for seamless connections. Their ability to

handle diverse fluids and pressures makes them indispensable for engineers seeking reliable boiler

pipeline protection and efficient system maintenance. Whether in water conservancy projects,

chemical processing, or mechanical power transmission, these couplings ensure long-term performance, safety,

and cost savings in demanding applications.

Considerations for Selection

Key factors to evaluate when selecting a coupling

-

Torque Requirements: Ensuring the coupling can handle the required torque.

-

Misalignment: Assess whether the system can accommodate axial, angular, or parallel

misalignment.

-

Environmental Conditions: Consider exposure to heat, chemicals, or other harsh

environments when choosing materials.

-

Flexibility and Damping: Important for reducing vibration and absorbing shock loads.