HDPE Coupling is a vital HDPE pipe fitting designed to connect two sections of high-density polyethylene (HDPE) pipes seamlessly, ensuring a leak-free and durable joint for fluid or gas transmission. These corrosion resistant HDPE joint solutions are manufactured using injection molding or butt fusion techniques, conforming to standards like ASTM F1055, ISO 4427, and AWWA C906. HDPE couplings are widely used in water supply networks, gas distribution lines, sewage systems, and industrial piping, providing excellent HDPE flexible coupling properties to accommodate thermal expansion, contraction, and minor misalignments while maintaining pressure integrity up to PN16 (160 psi).

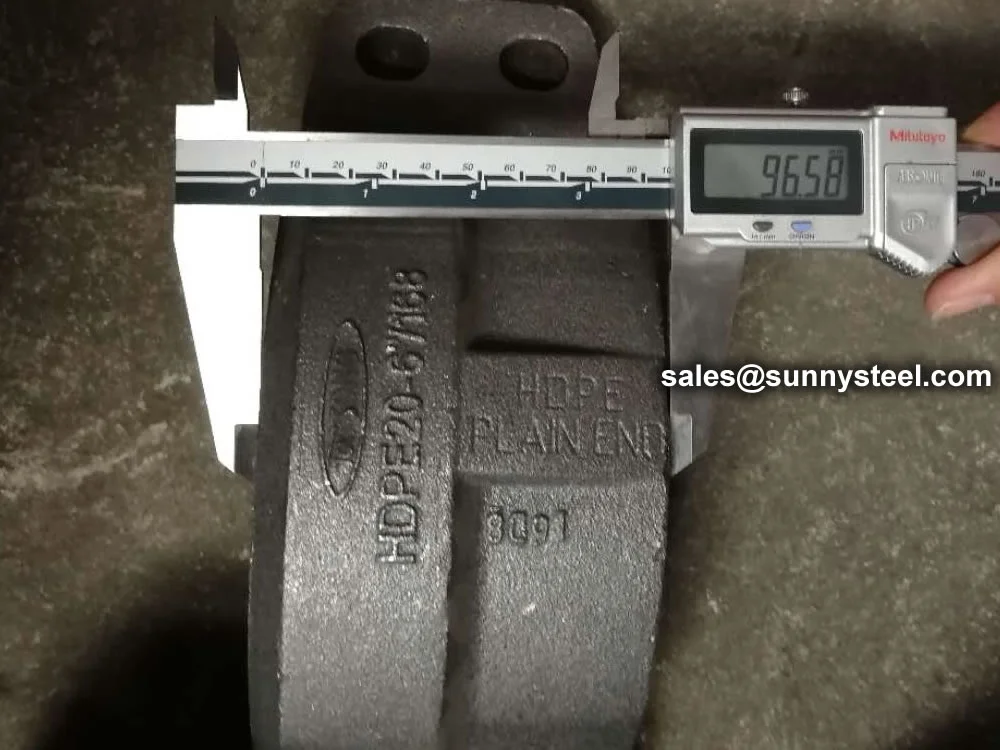

The production process for HDPE butt fusion coupling involves electrofusion or butt welding methods, where heating coils or plates fuse the coupling to the pipe ends, creating a homogeneous joint without additional fasteners. Available in types such as electrofusion couplings, compression couplings, and flanged adapters, these fittings support pipe diameters from DN20 to DN1200 (3/4" to 48"), with SDR ratings from 7.3 to 41 for varying pressure classes. Materials are virgin HDPE (PE100 or PE4710) with UV stabilizers and antioxidants, ensuring long-term corrosion resistance in buried, underground, or exposed applications. Surface finishes are smooth to prevent bacterial growth, and optional reinforcement rings enhance strength for high-pressure gas lines.

HDPE couplings are subjected to rigorous testing, including hydrostatic pressure, tensile pull-out, and fusion integrity tests, to comply with ASTM D2513 and ISO 8085 standards. The electrofusion process uses barcode technology for precise heating, achieving fusion joints with strength equal to or greater than the pipe itself, suitable for temperatures from -40°C to 60°C. These fittings excel in non-potable water, irrigation, mining slurries, and chemical transport, where their flexibility reduces stress from soil movement or thermal changes. Compression couplings, with stainless steel grip rings and EPDM seals, allow tool-free installation and accommodate pipe expansion without leaks.

Compared to metal couplings, HDPE pipe fittings offer superior chemical resistance and flexibility, eliminating the need for thrust blocks in straight runs due to the fused joint's integrity. Electrofusion couplings are ideal for repairs or transitions, while flanged HDPE couplings connect to metallic systems without corrosion issues. These HDPE butt fusion coupling solutions support PE80 and PE100 grades, with pressure ratings up to 25 bar for gas applications. Their lightweight design reduces transportation costs, and compatibility with butt fusion machines ensures quick field assembly, making them a preferred choice for large-scale projects like municipal water mains or oilfield gathering lines.

Addressing challenges like pipeline leaks, corrosion, and installation complexity, HDPE couplings deliver a flexible, durable solution for modern piping systems. Their homogeneous fusion joints and high-impact resistance make them ideal for underground installations, where they withstand external loads without failure. Whether in water distribution, gas pipelines, or industrial fluid transport, these corrosion resistant HDPE joint fittings ensure long-term performance, safety, and cost efficiency, providing essential boiler pipeline protection in diverse environments.

HDPE Coupling Technical SpecificationsNominal Size

mm/in | Pipe O.D

mm/in | Working Pressure

PSI/MPa | Bolt Size

No. - Size mm | Dimensions mm/in |

|---|

| Ø | L | H |

|---|

50

2 | 60.3

2.375 | 300

2.07 | 4 - M12 × 60 | 83

3.268 | 120

4.724 | 116

4.567 |

65

2½ | 76.1

3.000 | 300

2.07 | 4 - M10 × 55 | 89

3.504 | 116

4.567 | 118

4.646 |

80

3 | 88.9

3.500 | 300

2.07 | 4 - M12 × 75 | 117

4.606 | 166

6.535 | 118

4.646 |

100

4 | 114.3

4.500 | 300

2.07 | 4 - M12 × 75 | 143

5.630 | 201

7.913 | 147

5.787 |

150

6 | 168.3

6.625 | 300

2.07 | 4 - M12 × 75 | 178

7.008 | 235

9.252 | 118

4.646 |

150

6 | 168.3

6.625 | 300

2.07 | 4 - M16 × 85 | 202

7.953 | 252

9.921 | 150

5.906 |

200

8 | 219.1

8.625 | 300

2.07 | 4 - M16 × 85 | 258

10.157 | 320

12.598 | 152

5.984 |

250

10 | 273

10.748 | 300

2.07 | 4 - M20 × 100 | 313

12.323 | 390

15.354 | 165

6.496 |

300

12 | 323.9

12.748 | 300

2.07 | 4 - M20 × 120 | 367

14.449 | 455

17.913 | 183

7.205 |