What is a Valve?

A valve is a device that makes or stops the flow of media (liquid, gas, powder) in piping and equipment and controls its flow. Valves are crucial for creating complex piping networks that can efficiently transport various substances.

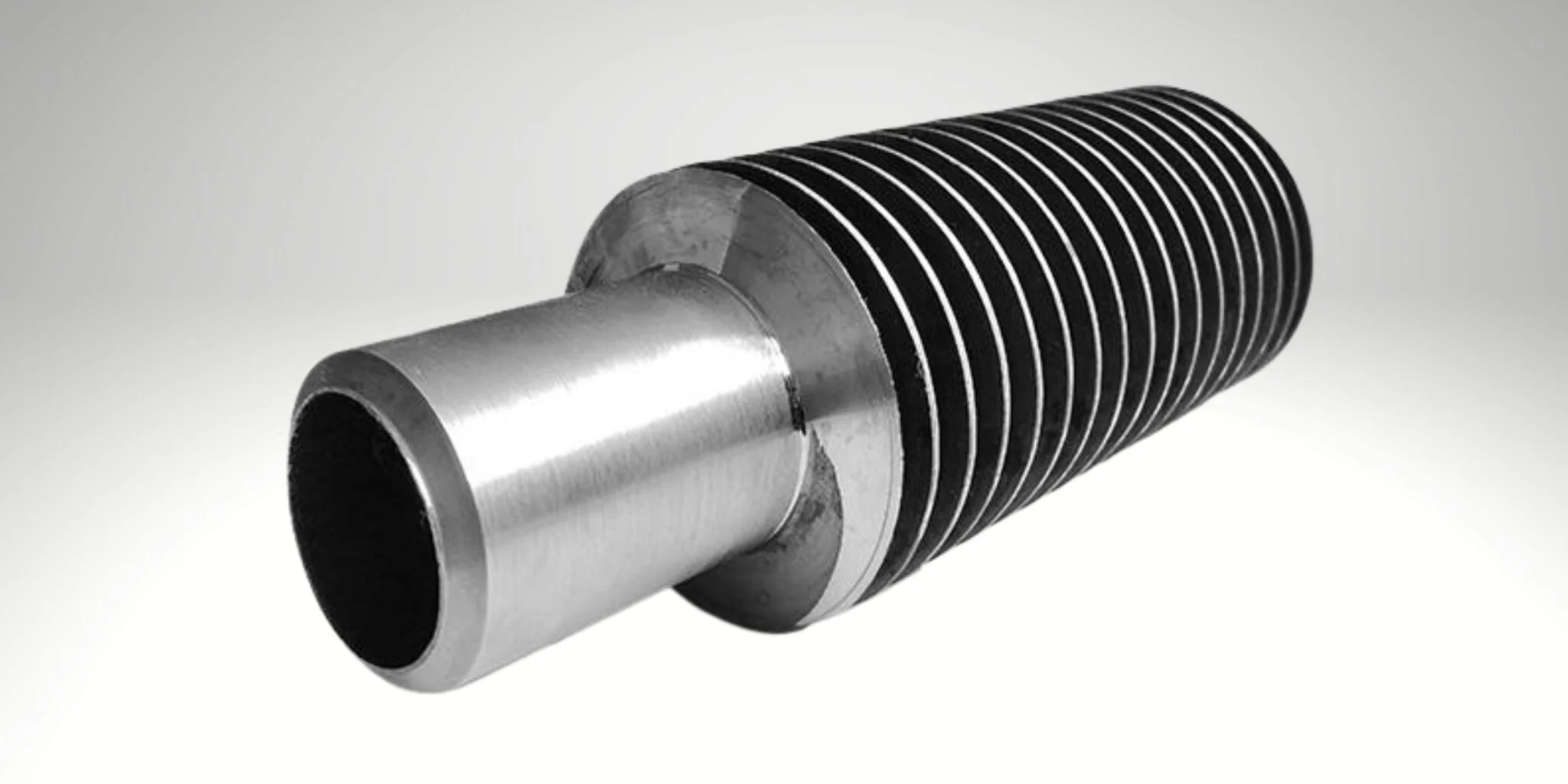

Industrial Valves are critical components designed to regulate, direct, or control the flow of fluids (liquids, gases, or slurries) in piping systems, ensuring leak-free operation and precise flow management. Complying with standards like ANSI, API, ASME, and GB, these corrosion resistant valves are made from materials such as stainless steel (AISI 304/316), titanium, nickel alloys, and bronze, offering robust boiler pipeline protection. Used in industries like petrochemical, water supply, power generation, and mining, they handle pressures from 0.0013 MPa to 1000 MPa and temperatures from -270°C to 1430°C, supporting applications from cryogenic LNG to high-temperature steam systems.

Ball Valves feature a pivoting, perforated ball for quick shut-off and precise flow control, ideal for oil and gas pipelines. Available in sizes from 1/4" to 48" (DN6 to DN1200), they support threaded, flanged, or welded connections. Butterfly Valves, with a rotating disc, provide efficient shut-off and throttling in water supply and HVAC systems, offering compact design and low flow resistance. Check Valves prevent backflow in pump and steam trap outlets, with swing, lift, or wafer designs ensuring one-way flow. Control Valves regulate flow, pressure, or temperature via adjustable passages, while Cryogenic Valves secure liquified gases like LNG at temperatures as low as -196°C. Gate Valves and Globe Valves offer linear or throttling control for water and steam systems, with globe valves providing better regulation but higher pressure loss.

Manufactured through forging, casting, or machining, industrial valves undergo rigorous testing, including hydrostatic, leakage, radiographic, and ultrasonic inspections, to meet standards like API 598 and GB/T13927. Stainless steel valves (AISI 316) resist corrosion in acidic or saline environments, while titanium and nickel alloys excel in extreme conditions like chemical processing. Surface treatments like passivation or ceramic lining enhance durability in abrasive or high-temperature applications, such as boiler tubing or slurry transport. Valves support manual, electric, pneumatic, or hydraulic actuation, with nominal diameters from DN6 to DN1400, catering to small-scale instrumentation or large-scale pipelines.

Compared to standard fittings, industrial valves offer precise flow control, backflow prevention, and pressure regulation, making them essential for dynamic systems. Certified by NSF/ANSI 61 for potable water or API 6D for pipeline safety, they ensure compliance with industry standards. Corrosion resistant valves like those in duplex stainless steel or Hastelloy handle corrosive media, while ceramic-lined or rare earth alloy valves resist wear in mining or power generation. Their versatility extends to maintenance, with designs allowing easy access for repairs. Sunny Steel’s white-glove service ensures timely delivery of high-quality valves tailored to engineering specifications.

Addressing challenges like fluid backflow, corrosion, and pressure fluctuations, Industrial Valves deliver reliable, efficient solutions for piping systems. Their robust construction, corrosion-resistant materials, and precise control mechanisms make them ideal for engineers seeking durable boiler pipeline protection. From water treatment to petrochemical refineries, these valves ensure safety, performance, and longevity in demanding industrial environments.