Butterfly Valve is a high-performance flow control device designed for efficient

regulation and shut-off in industrial piping and HVAC systems. Compliant with standards like API 609, ASME B16.34,

and EN 593, these industrial butterfly valves are constructed from materials such as ductile iron,

stainless steel (AISI 316/304), or carbon steel, offering excellent corrosion resistant butterfly

valve properties. Widely used in water treatment, HVAC, chemical processing, and oil and gas

applications, they provide reliable pipeline flow control under pressures up to 300 PSI and

temperatures ranging from -29°C to 200°C, ensuring versatility and durability in diverse environments.

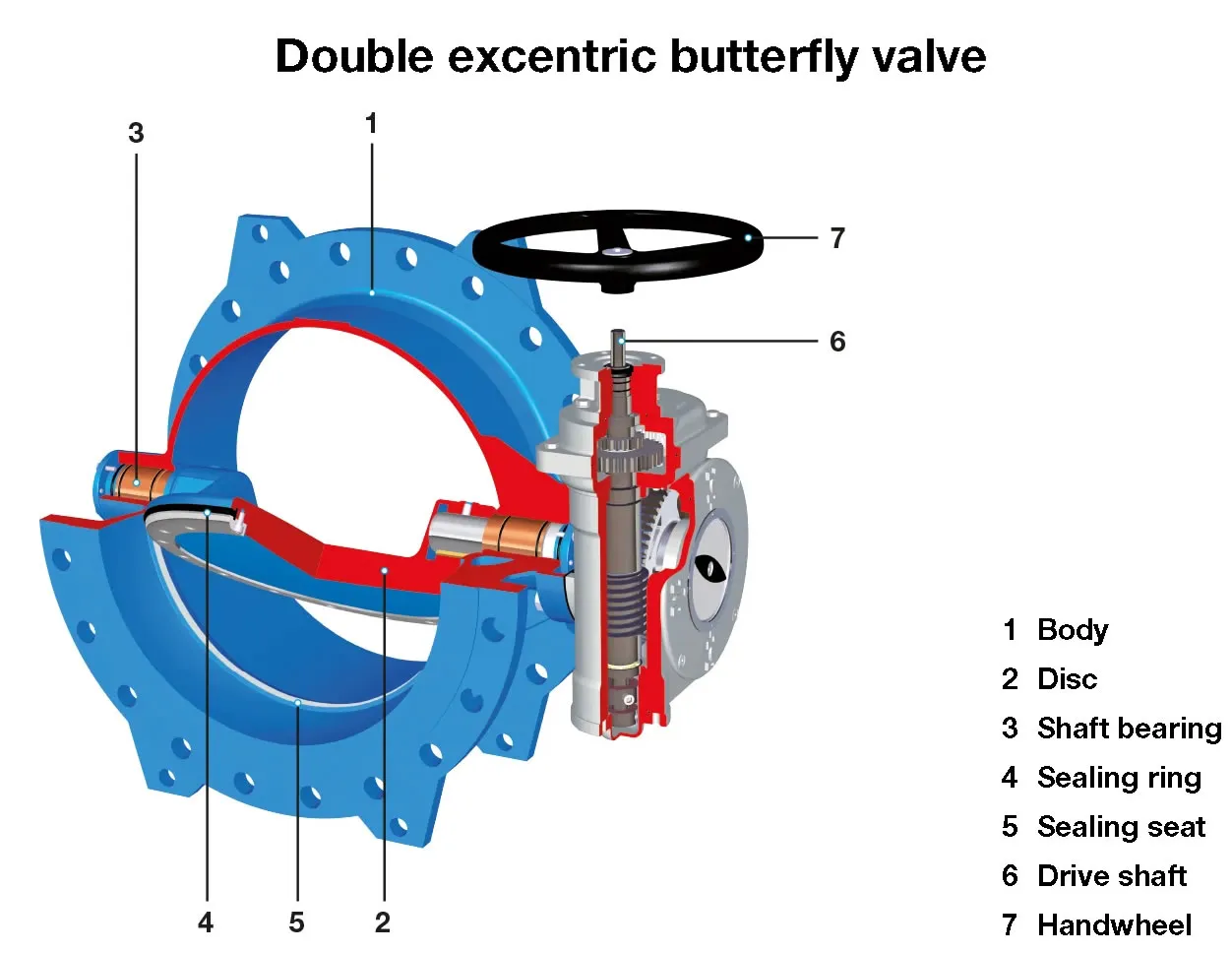

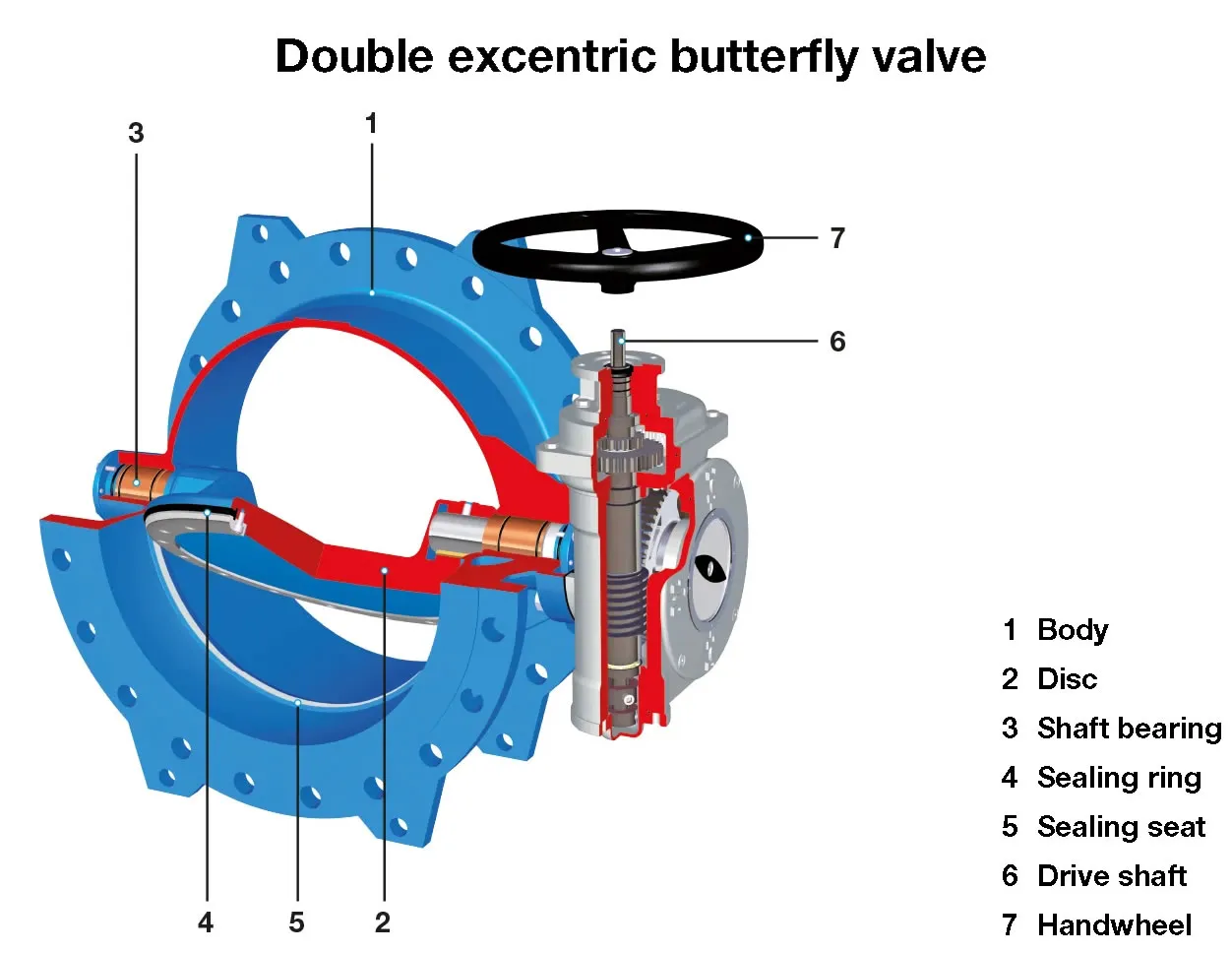

Manufactured through precision casting or forging, the butterfly valve features a disc that rotates

90° to control flow, offering low-pressure drop and quick operation. Available in sizes from 2" to 72" (DN50 to

DN1800), they support wafer, lug, or flanged connections, with resilient seated or high-performance designs.

Resilient seated valves use EPDM, NBR, or PTFE seals for leak-free performance, while high-performance models with

metal seats handle higher temperatures and pressures. Surface treatments like epoxy coating or nickel plating

enhance corrosion resistance, making them suitable for water, air, steam, and mildly corrosive media in

resilient seated butterfly valve applications.

Butterfly Valves undergo rigorous testing, including hydrostatic, leakage, and cycle tests, to

comply with API 598 and EN 12266 standards. With a minimum tensile strength of 485 MPa and yield strength of 275 MPa

for ductile iron, these valves ensure durability in demanding conditions. Their quarter-turn operation enables rapid

flow control, while the streamlined disc design minimizes turbulence and pressure loss, making them ideal for HVAC

and water distribution systems. Features like ISO 5211 mounting pads, anti-static devices, and lockable handles

enhance operational safety and compatibility with pneumatic or electric actuators.

Compared to gate or ball valves, the butterfly valve offers a compact, lightweight design with

lower installation and maintenance costs, making it ideal for large-diameter pipelines. Certified by API 609 for

performance and WRAS for potable water, these valves support manual, gear-operated, or automated actuation for

versatile control. Their bidirectional sealing capability ensures reliable performance in both flow directions,

while specialized options, such as triple offset or cryogenic designs, cater to niche applications like chemical

processing or LNG systems. The valves’ robust construction resists wear and corrosion, extending service life in

harsh environments.

Addressing challenges like corrosion, leaks, and flow inefficiencies, Butterfly Valves deliver

reliable, cost-effective solutions for industrial piping systems. Their corrosion-resistant materials, efficient

design, and easy operation make them a preferred choice for engineers seeking durable high-performance

butterfly valves. Backed by Sunny Steel’s white-glove service, these valves ensure exceptional

performance, safety, and longevity in water treatment, HVAC, and chemical applications.

Ball Valve Construction

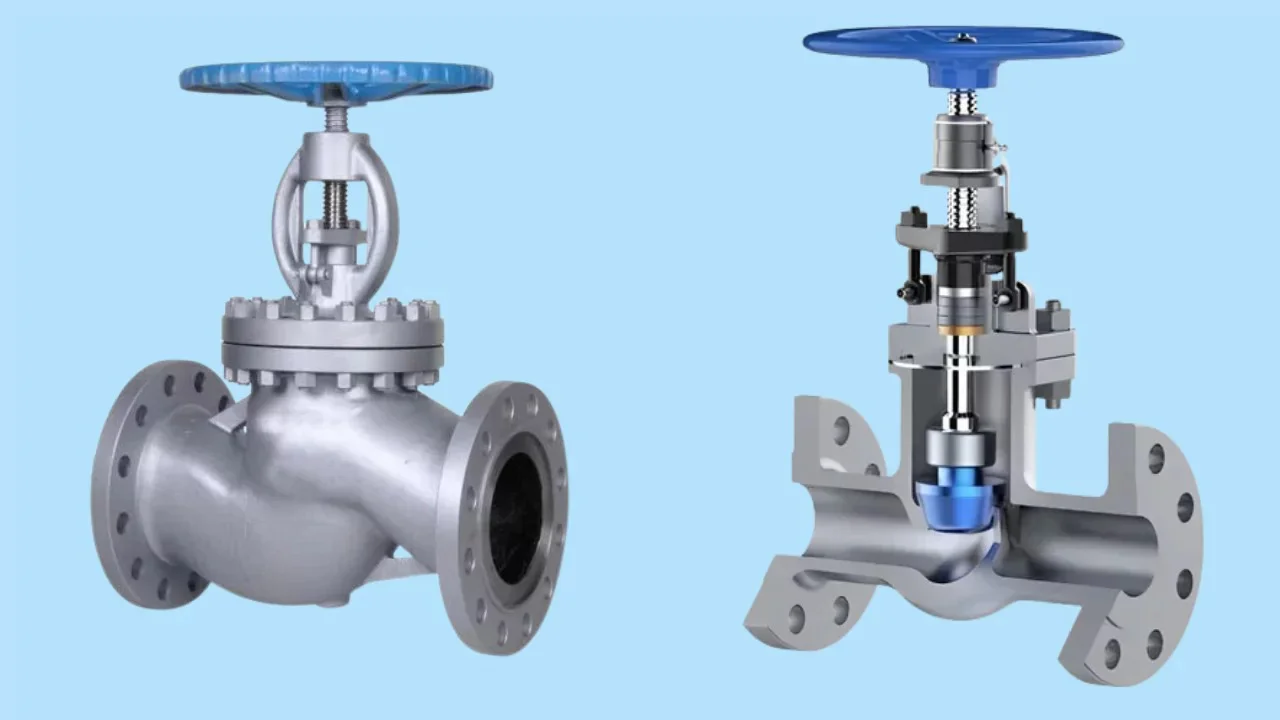

A ball valve consists of several critical components that work together to ensure

durability, tight sealing, and precise flow control.

Body

The main housing that supports all parts, providing strength and structural stability.

Ball

A perforated sphere that regulates flow by rotating with the stem.

Stem

Connects the ball to the actuator or handle, transferring torque for operation.

Bonnet

Protects and seals the stem area with packing or O-rings to prevent leakage.

Seat

Non-metallic inserts like PTFE or Nylon ensure leak-tight sealing and smooth operation.

Actuator

Provides manual or automated operation. Larger valves may use gearboxes for torque reduction.

Additional Features

- Flanges provided at suction and discharge sides for easy piping connection.

- Packing or O-rings ensure tight sealing around stem and bonnet.

- Non-metallic seats limit use in high-temperature environments.

Advantages of Butterfly Valves

Butterfly valves offer several advantages over other valve types, especially for sizes above DN 200 (200 mm).

Lightweight and Compact

Compact design with smaller face-to-face dimensions reduces installation footprint and lowers costs for labor, equipment, and piping support.

Low Maintenance

Simple design with few moving parts minimizes wear points and significantly reduces maintenance requirements.

Fast Acting

90° handle rotation allows quick opening/closing. Larger valves may use gearboxes to reduce torque and simplify operation.

Low Cost

Fewer materials and simpler manufacturing make butterfly valves a cost-effective option, especially for sizes above DN 300.

Versatility

Suitable for a wide range of applications, including underground installations, making them highly versatile.

Custom Advantage

Add another key advantage or special feature here. This template can be reused for any additional benefit.