Compact Wafer Design With Flange Compatibility For Seawater Pipeline Control

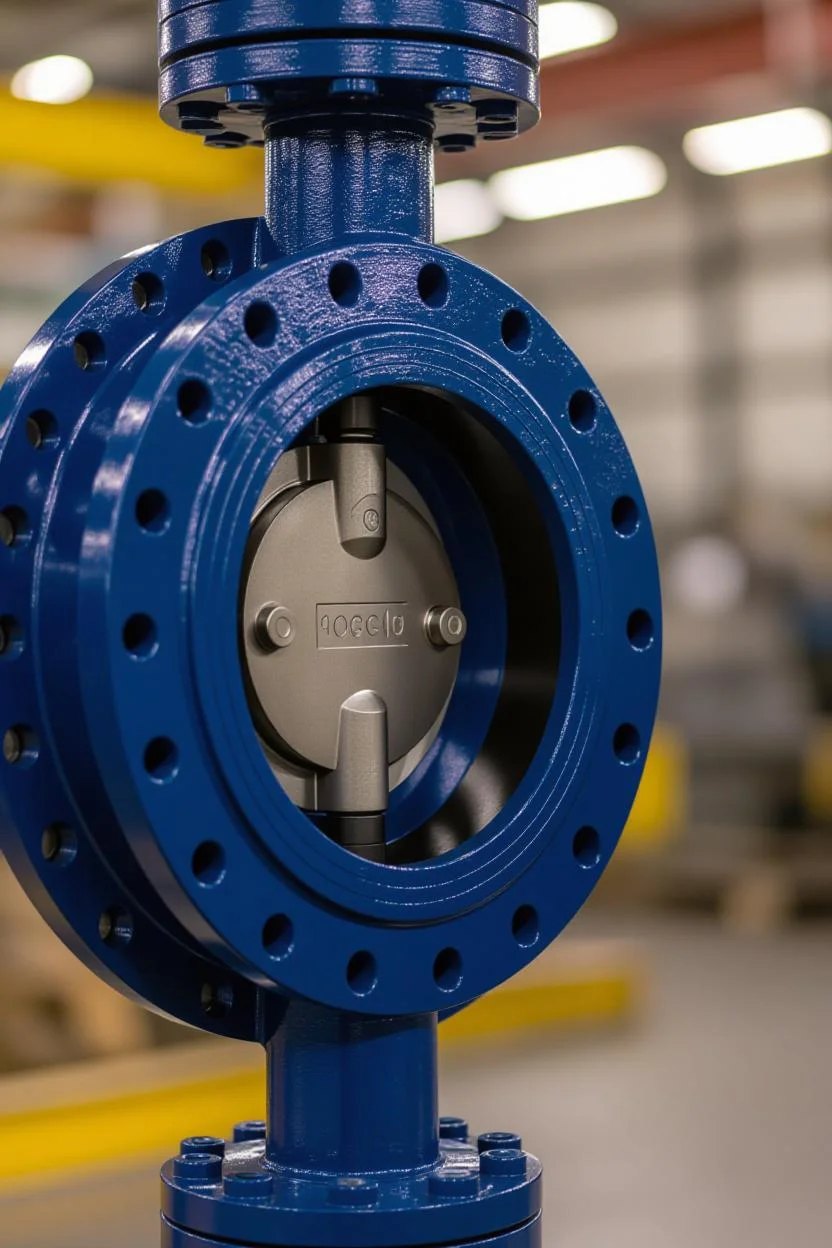

The marine wafer flange butterfly valve delivers superior corrosion resistance in harsh seawater environments, featuring a compact wafer design that clamps securely between flanges for easy installation in shipbuilding and offshore systems.

Compact Wafer Design With Flange Compatibility For Seawater Pipeline Control

The marine wafer flange butterfly valve delivers superior corrosion resistance in harsh seawater environments, featuring a compact wafer design that clamps securely between flanges for easy installation in shipbuilding and offshore systems.

The Marine Wafer Flange Butterfly Valve is a high-performance, compact flow control solution designed specifically for demanding marine and offshore environments. Featuring a thin wafer-style body that fits seamlessly between two pipeline flanges, this wafer flange valve eliminates the need for additional bolting hardware, saving space and installation time in tight shipboard compartments. Constructed primarily from marine-grade 316 stainless steel (CF8M equivalent) for exceptional seawater corrosion resistance, it withstands exposure to saltwater, chemicals, and abrasive media without degradation, making it a preferred choice for shipbuilding valve applications in cooling water systems, fuel lines, and ballast controls.

This marine butterfly valve operates on a simple quarter-turn mechanism, where a disc rotates 90 degrees around a stainless steel stem to regulate or isolate flow of liquids, gases, or slurries. Available in sizes from DN50 to DN1200, it supports pressure ratings up to 16 bar (ANSI 150) and temperatures ranging from -20°C to 120°C, depending on seat material—EPDM for general water service or Viton for chemical resistance. Compliant with international standards like API 609 for design and testing, ISO 5752 for face-to-face dimensions, and EN 593 for metallic butterfly valves, it ensures bubble-tight shutoff and bi-directional sealing. Certifications from DNV, ABS, and Lloyd's Register further validate its reliability for industrial flow control in petroleum, petrochemical, and naval vessels.

Key to its longevity is the robust material selection: the body and disc provide mechanical strength against erosion and fatigue, while the resilient seat (EPDM or PTFE) forms a zero-leakage barrier even under dead-end conditions. Unlike bulkier double-flanged alternatives, the lug type butterfly variant allows end-of-line service with threaded lugs for secure bolting, ideal for maintenance without system shutdown. Surface treatments like epoxy coating enhance abrasion resistance, protecting against marine biofouling and cathodic reactions in seawater corrosion resistance scenarios. Its lightweight design (up to 50% lighter than gate valves) and low torque requirements make it compatible with lever, gear, or pneumatic actuators, facilitating automation in HVAC, fire-fighting, and irrigation systems on board.

In comparison to standard industrial valves, the Marine Wafer Flange Butterfly Valve excels in cost-effectiveness—offering 30-40% savings on materials—while delivering superior performance in corrosive settings. For instance, its high chromium-molybdenum content resists pitting from chlorides, outperforming carbon steel options in offshore oil and gas pipelines. The valve's versatility extends to custom configurations, including extended necks for insulation or ISO 5211 mounting pads for direct actuator integration, ensuring adaptability for shipbuilding valve projects. Rigorous testing per ASTM F1199 and BS 6364 confirms tensile strength above 515 MPa and yield strength of 205 MPa, guaranteeing operation in cryogenic or high-vibration marine conditions.

Addressing common challenges like pipeline leaks and premature wear, this wafer flange valve incorporates a one-piece stem for blowout-proof integrity and spherical disc edges for reduced friction and extended seat life—up to three times longer than conventional designs. Whether throttling flow in seawater desalination plants or providing emergency isolation in naval vessels, it minimizes downtime and enhances safety. For enhanced protection, optional 3LPE coatings or FBE linings further boost seawater corrosion resistance, making it an essential component for sustainable industrial flow control in global maritime operations.

Engineered to meet diverse industrial needs with robust materials and versatile designs.

| Organization | Standard | Description |

|---|---|---|

| ANSI | American National Standards Institute | General industrial standards |

| API | American Petroleum Institute | Standards for oil and gas industry |

| ASME | American Society of Mechanical Engineers | Boiler and pressure vessel codes |

| BS | British Standards | UK national standards |

| GB, JB, HG | China Valve Standards | Chinese national and industry standards |

Upstream, midstream, and downstream operations, including drilling, refining, and transportation.

Handling corrosive and hazardous chemicals in various chemical plants.

Steam, water, and fuel systems in thermal, nuclear, and hydroelectric plants.

Municipal water supply, wastewater treatment, and industrial water management.

Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Sterile and hygienic applications, precise flow control in sensitive industries.

The wafer flange butterfly valve is a high-efficie...

The wafer butterfly valve provides reliable flow c...

Loose liner wafer butterfly valve offers efficient...