Compact Non-return Design With Resilient Seals For Industrial Flow Control

The rubber seal dual plate check valve provides efficient backflow prevention with durable rubber seals for water, oil, and sewage systems, ensuring low pressure drop and corrosion resistance up to pn16 and 120°c.

Compact Non-return Design With Resilient Seals For Industrial Flow Control

The rubber seal dual plate check valve provides efficient backflow prevention with durable rubber seals for water, oil, and sewage systems, ensuring low pressure drop and corrosion resistance up to pn16 and 120°c.

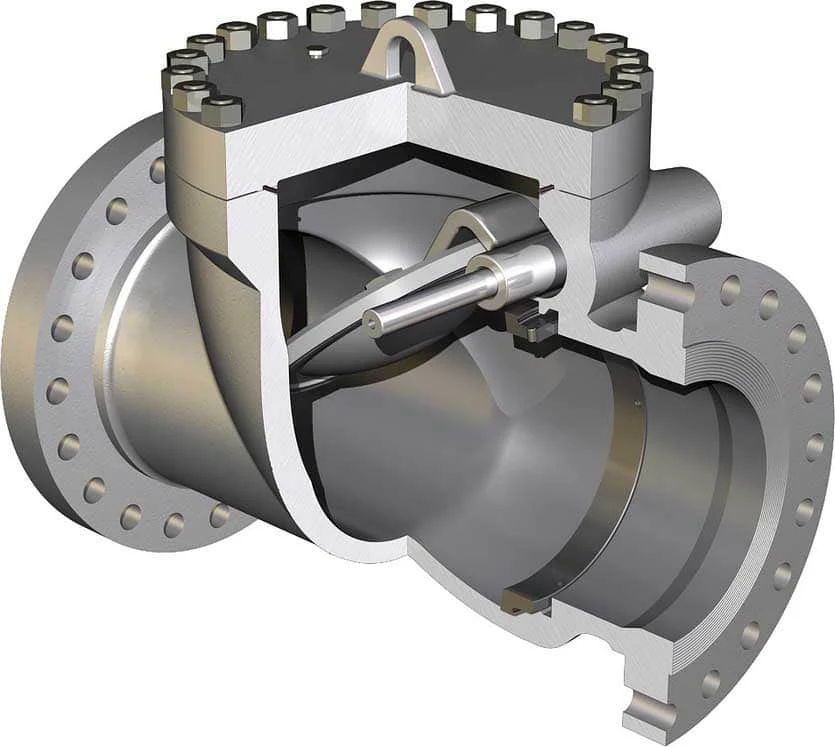

The Rubber Seal Dual Plate Check Valve is a high-performance non-return valve engineered for reliable backflow prevention in industrial pipelines, featuring resilient rubber seals for bubble-tight shutoff and minimal pressure loss. Designed with a compact wafer-style body and two semi-circular plates that open parallel to the flow, this dual plate check valve automatically prevents reverse flow, protecting pumps and equipment from damage in water, oil, sewage, and chemical systems. Constructed from ductile iron (GGG40) or stainless steel with EPDM or NBR rubber seals, it offers superior corrosion resistance, making it ideal for demanding applications in wastewater treatment, HVAC, and marine environments.

This rubber seal check valve operates via flow-activated plates supported by torsion springs for quick closure, reducing water hammer and ensuring response times under 0.1 seconds. Available in sizes from 2" to 80" (DN50 to DN2000) with wafer or lug end connections per ISO 5752 and ASME B16.10, it supports pressure ratings up to PN16 (ANSI 150) and temperatures from -20°C to 120°C, depending on seal material—EPDM for water and mild chemicals or Viton for oils and hydrocarbons. Compliant with API 594 for design and testing, BS 1868 for swing check valves, and EN 12334 for industrial valves, it undergoes 100% hydraulic shell and seat tests at 1.1x rated pressure, plus low-pressure air tests for zero leakage. Certifications like NSF 61 for potable water and DNV for marine use validate its performance in backflow prevention valve setups.

The valve's retainerless design eliminates body perforations, preventing emissions and enhancing safety, while the vulcanized rubber seals provide high-integrity sealing with bonding strength exceeding 1.732 MPa to avoid delamination. Unlike single-plate swing valves, the dual plate check valve offers 70% weight reduction and lower torque, with plates that avoid dragging on seats for extended life up to 10,000 cycles. Surface treatments like epoxy coating or full rubber lining boost corrosion resistance against chlorides, acids, and biofouling, ideal for seawater or sewage applications. The low cracking pressure (0.02-0.05 bar) and minimal pressure drop (KVS values up to 5000) optimize flow efficiency, while thrust bearings reduce friction for smooth operation in high-velocity flows.

In comparison to lift or piston check valves, the rubber seal check valve excels in horizontal or vertical installations with bidirectional sealing capability, reducing installation costs by 40% due to its lightweight construction. Optional full rubber lining enhances abrasion resistance for slurries or solids-laden media, while stainless steel hinges and springs ensure durability in corrosive settings. Rigorous testing per API 598, including hydrostatic, pneumatic, and cycle endurance, confirms tensile strengths above 420 MPa for ductile iron bodies, guaranteeing integrity under thermal cycling and surges. Custom features like extended necks for insulation or fire-safe API 607 configurations support versatility in power generation and petrochemical pipelines.

Addressing challenges such as water hammer, seat wear, and backflow contamination in non-return valve applications, this corrosion resistant check valve incorporates shock bumpers and independent springs for even force distribution, minimizing vibration and extending service life. Its adaptability to contaminated media, with self-cleaning plate action, makes it suitable for sewage or pulp industries, while eco-friendly materials meet EPA standards for low-emission operations. Whether installed in pump discharge lines or flood control reservoirs, the Rubber Seal Dual Plate Check Valve delivers cost-effective, reliable backflow prevention valve performance for global industrial needs.

Engineered for efficient backflow prevention with resilient rubber seals and compact design.

Check valves are essential components that ensure safe and efficient operation of fluid systems by controlling flow direction and preventing backflow.

Permits fluid flow in one direction and automatically closes to prevent backflow in the opposite direction.

Uses hinged or spring-loaded flaps, discs, or pistons that open with forward flow and close with backflow.

Includes swing, lift, ball, and diaphragm check valves, each suited for different applications and conditions.

Widely used in water, wastewater, oil & gas, HVAC, and many other industrial applications.

Helps avoid sudden pressure surges caused when fluid flow is abruptly stopped.

Simple and reliable design ensures long-term efficiency with minimal upkeep.

Check valves are one-way valves that allow fluid to flow in a single direction and automatically prevent backflow. They are widely used in pipelines to protect pumps, piping, and other equipment. Backflow preventers apply additional pressure to ensure water flows only one way, providing extra protection for drinking water systems.

Allows fluid to flow in one direction and automatically prevents backflow.

Protects pumps, piping, and other equipment.

Check Valve: Simple, hinged or spring-loaded disc.

Backflow Preventer: Uses pressure and fail-safes to protect drinking

water.

Hinged disc swings open to allow forward flow and closes to prevent backflow.

Low turbulence and low pressure drop.

Piston or ball lifts from the seat to allow flow.

Suitable for high-pressure and high-velocity systems; can be installed horizontally or

vertically.

Ball Check, Butterfly Check, and Tilting-Disk Check valves.

Each design is optimized for specific applications and conditions.

- Unidirectional flow control

- Low maintenance

- Prevents water hammer

- Wide range of sizes & materials

- Versatile in water, oil, gas, and HVAC systems

| Feature | Check Valve | Backflow Preventer |

|---|---|---|

| Primary Function | Allows flow in one direction; prevents reverse flow automatically | Prevents contamination of drinking water; ensures flow only in one direction using pressure & fail-safes |

| Mechanical Design | Hinged disc, flap, piston, or ball opens with flow and closes with backflow | Multiple valves, check mechanisms, or air gaps to enforce one-way flow |

| Application | Pipelines, pumps, HVAC, water & wastewater, oil & gas | Potable water supply, irrigation, hospitals, schools, commercial buildings |

| Pressure Handling | Medium to high pressure; depends on valve type | High reliability; designed for pressurized systems to prevent contamination |

| Maintenance | Low; simple design, few moving parts | Moderate; more components, periodic inspection recommended |

| Reliability | Good for general use; may fail under extreme conditions | Highly reliable; multiple fail-safes for drinking water protection |

| Organization | Standard | Description |

|---|---|---|

| ANSI | American National Standards Institute | General industrial standards |

| API | American Petroleum Institute | Standards for oil and gas industry |

| ASME | American Society of Mechanical Engineers | Boiler and pressure vessel codes |

| BS | British Standards | UK national standards |

| GB, JB, HG | China Valve Standards | Chinese national and industry standards |

Upstream, midstream, and downstream operations, including drilling, refining, and transportation.

Handling corrosive and hazardous chemicals in various chemical plants.

Steam, water, and fuel systems in thermal, nuclear, and hydroelectric plants.

Municipal water supply, wastewater treatment, and industrial water management.

Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Sterile and hygienic applications, precise flow control in sensitive industries.

The lift check valve ensures reliable backflow pre...

The swing check valve is a high-performance non-re...

Upon encountering a specified flow rate, the disc ...

The wafer flange dual plates check valve ensures e...

The forged lift piston check valve ensures reliabl...