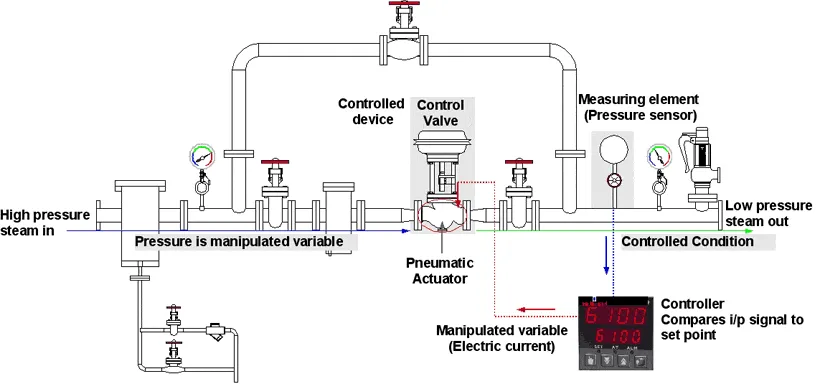

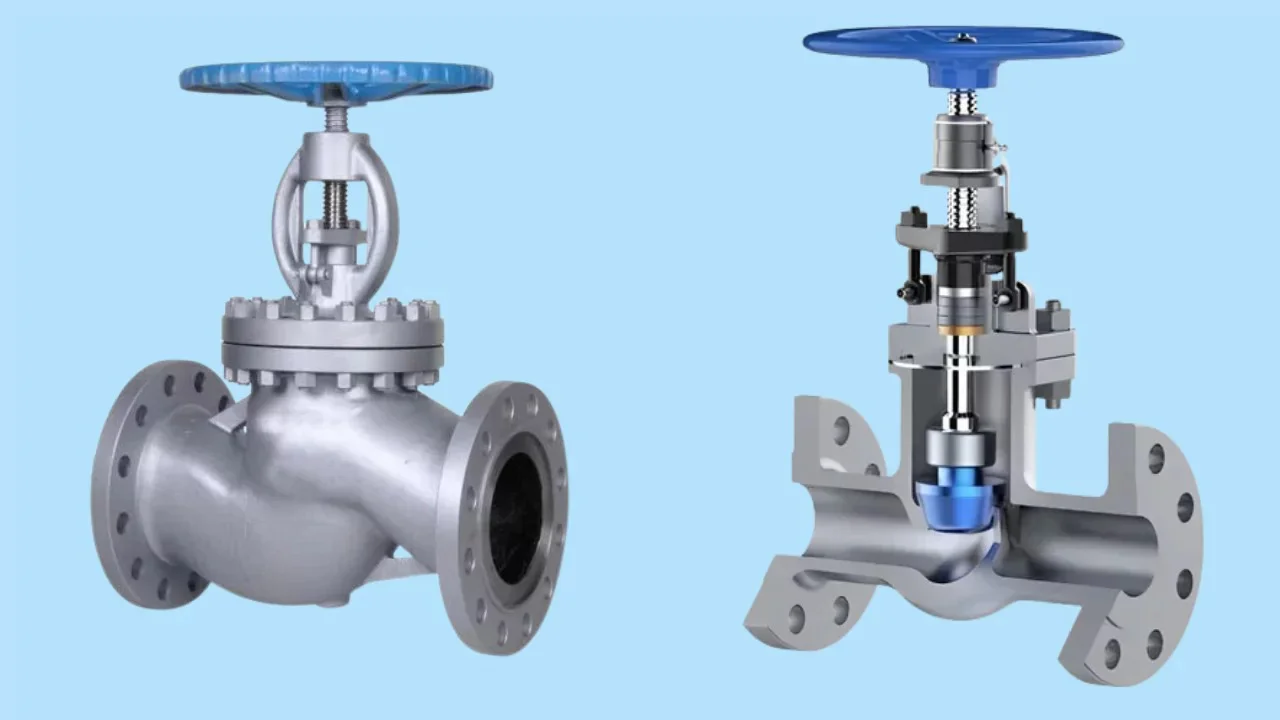

The Control Valve is a precision-engineered valve designed for accurate flow regulation in industrial pipelines, offering reliable throttling and shutoff for water, oil, gas, and chemical systems. Utilizing a globe, butterfly, or ball valve configuration with advanced actuators (pneumatic, electric, or hydraulic), it ensures precise control of flow rate, pressure, and temperature. Constructed from materials like ASTM A216 WCB carbon steel, ASTM A351 CF8M stainless steel, or alloy steels, with optional coatings such as PTFE or epoxy, it provides exceptional corrosion resistance, making it ideal for industrial flow regulation in oil and gas, petrochemical, power generation, and water treatment industries.

Compliant with ASME B16.34 for manufacturing and API 609 or IEC 60534 for design and performance, the control valve is available in sizes from 1/2" to 24" (DN15 to DN600) with flanged, threaded, or butt-weld end connections per ASME B16.5 and B16.25. It supports pressure ratings up to PN40 (ANSI Class 150-600) and temperatures from -29°C to 450°C, depending on seat materials like PTFE for low temperatures or metal-to-metal for high-temperature applications. The valve’s trim, designed with equal percentage, linear, or quick-opening flow characteristics, allows precise modulation with Cv values up to 12,000, optimizing flow control valve performance. Certifications such as SIL 3 per IEC 61508 and NACE MR0175 for sour service ensure reliability in critical applications.

The valve’s robust construction features a forged or cast body with a balanced plug or cage-guided trim, reducing cavitation and noise in high-pressure differential systems. Its corrosion resistant valve properties are enhanced by coatings and linings that protect against aggressive media like acids, seawater, or slurries, extending service life up to three times longer than uncoated valves in corrosive environments. Actuation systems, compatible with 4-20mA or digital protocols like HART or Foundation Fieldbus, enable precise automation in SCADA-integrated systems. Rigorous testing per API 598, including hydrostatic, pneumatic, and leakage tests, confirms tensile strengths above 485 MPa, ensuring durability under cyclic loading and thermal stress.

Compared to gate or check valves, the control valve offers superior throttling precision, with flow accuracy within ±2% of setpoint, making it ideal for processes requiring tight control, such as boiler feedwater regulation or gas pressure management. Its modular design allows for easy trim replacement and maintenance, reducing downtime in precision control valve applications. Optional features like anti-cavitation cages, low-noise trims, or bellows seals for zero-emission compliance enhance versatility for chemical plants, HVAC systems, and marine applications. The valve’s ability to handle high-viscosity fluids and abrasive slurries ensures consistent performance in demanding conditions.

Addressing challenges like flow instability, pipeline corrosion, and fugitive emissions, the control valve incorporates advanced packing systems and durable seals to ensure long-term integrity. Its compatibility with global flange standards (ANSI, DIN, JIS) and coatings like 3LPE or FBE ensures applicability in diverse environments, from buried pipelines to offshore platforms. Whether regulating flow in refinery processes or maintaining pressure in water distribution systems, the Control Valve delivers reliable, low-maintenance industrial flow regulation for global industrial operations.

FAQs

Engineered for precise flow regulation with durable materials and advanced automation.

Advanced trim and actuators ensure ±2% flow accuracy in flow control valve applications.

Yes, it supports up to 450°C with metal seats, ideal for industrial flow regulation.

It meets ASME B16.34, API 609, IEC 60534, and SIL 3 for corrosion resistant valve reliability.

Control valve offers precise throttling, unlike gate valves, for superior precision control valve performance.