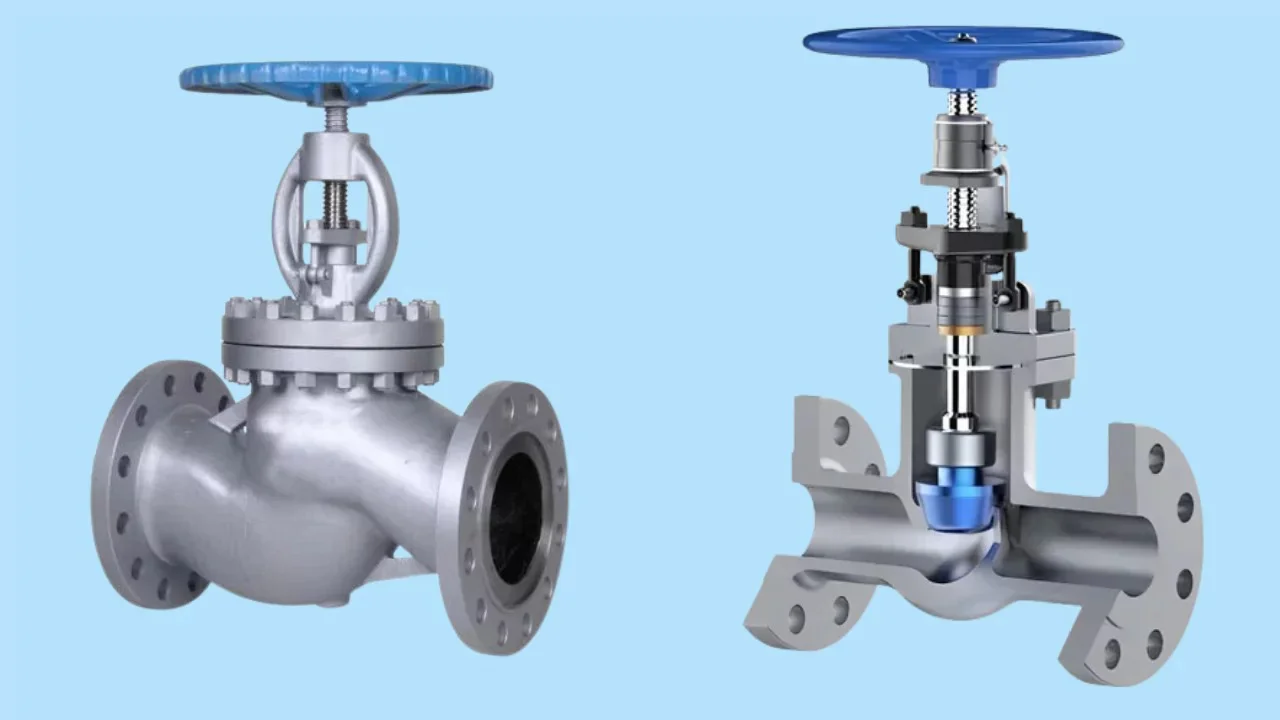

The Cryogenic Valve is a specialized flow control device engineered for extreme

low-temperature environments, providing reliable shutoff and throttling in liquefied natural gas (LNG), industrial

gases, and cryogenic fluid systems. Designed to withstand temperatures as low as -196°C, this low

temperature valve features extended bonnets and specialized packing to prevent stem freeze-up and

material embrittlement, ensuring safe operation in harsh cryogenic conditions. Constructed from austenitic stainless

steels like 304L or 316L, with optional bronze or aluminum alloys for specific applications, it offers superior

corrosion resistance against moisture-induced pitting and thermal contraction stresses, making it

essential for LNG terminals, air separation plants, and medical gas distribution.

Compliant with API 6D for pipeline valves and BS 6364 for cryogenic service, the cryogenic gate

valve or ball variant is available in sizes from 1/2" to 24" (DN15 to DN600) with flanged, welded, or

threaded ends per ASME B16.5 and B16.25. It supports pressure ratings up to PN40 (ANSI Class 150-600) and full

vacuum capability, with extended stems (250-500mm) to keep the packing above the cold zone and bellows seals for

zero-leakage in hazardous applications. The valve's low thermal conductivity materials minimize heat ingress,

preserving cryogenic fluid integrity, while fire-safe designs per API 607 ensure reliability in emergency scenarios.

Testing includes cryogenic hydrostatic tests at -196°C and helium leak detection for bubble-tight shutoff,

confirming compliance with EN 12516 for pressure equipment.

The LNG ball valve variant features a trunnion-mounted ball with floating seats for low torque

operation, reducing actuator requirements in automated systems, while gate types offer full-port flow for minimal

pressure drop (Cv up to 15,000). Its industrial cryogenic valve construction resists brittle

fracture through impact-tested materials (Charpy V-notch >27J at -196°C), ensuring safety in seismic or

vibration-prone installations. Surface treatments like electropolishing or passivation enhance corrosion

resistance, preventing oxidation in moist cryogenic environments, and optional position indicators

support remote monitoring via SCADA. With tensile strengths above 515 MPa and yield strengths of 205 MPa, the valve

withstands thermal cycling without deformation, ideal for regasification plants or hydrogen liquefaction facilities.

Compared to standard valves, the cryogenic valve excels in preventing leaks and ice formation, with

a 3-5 times longer service life due to specialized metallurgy and design features like insulated bonnets. Its

compact footprint suits space-constrained LNG carriers or cryogenic storage tanks, while customizable actuators

(pneumatic or electric) enable automation for precise flow control. The valve's ability to handle multiphase flows

without galling or seat damage makes it superior for dynamic applications, reducing operational costs by minimizing

downtime in critical cryogenic processes.

Addressing challenges like thermal contraction, fugitive emissions, and material brittleness in low

temperature valve systems, this cryogenic gate valve incorporates

double-block-and-bleed configurations and secondary seals for enhanced safety. Its compatibility with international

standards like MSS SP-134 for cryogenic valves ensures global applicability, from offshore FPSOs to biomedical

cryostorage. Whether isolating LNG transfer lines or regulating helium flows in superconductors, the Cryogenic Valve

delivers unmatched reliability, safety, and efficiency for extreme low-temperature industrial operations.