Gate Valve

The gate valve provides reliable on-off flow control for oil, gas, and water pipelines, featuring corrosion-resistant materials and robust design for high-pressure systems up to pn40 and 425°c.

The gate valve provides reliable on-off flow control for oil, gas, and water pipelines, featuring corrosion-resistant materials and robust design for high-pressure systems up to pn40 and 425°c.

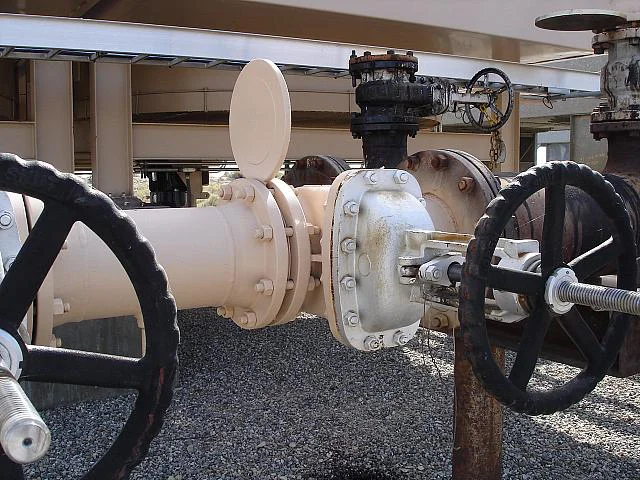

The Gate Valve is a robust, linear-motion valve engineered for reliable on-off flow control in industrial pipelines, offering full flow capacity and tight shutoff for oil, gas, water, and chemical systems. Featuring a wedge-shaped gate and durable construction from materials like ASTM A216 WCB carbon steel or ASTM A351 CF8M stainless steel, this industrial gate valve ensures superior corrosion resistance and longevity in harsh environments. Designed for high-pressure applications up to PN40 (ANSI Class 150-600) and temperatures up to 425°C, it is ideal for pipeline isolation in refineries, petrochemical plants, power generation, and water treatment facilities.

Compliant with API 600 for cast steel valves and ASME B16.34 for pressure-temperature ratings, the wedge gate valve is available in sizes from 1/2" to 48" (DN15 to DN1200) with flanged, butt-weld, or threaded end connections per ASME B16.5 and B16.25. The valve’s solid or flexible wedge design ensures tight sealing against bidirectional pressure, with metal or resilient seats (e.g., PTFE or Stellite) providing Class VI shutoff per API 598. Rigorous testing, including hydrostatic, pneumatic, and shell tests, confirms tensile strengths above 485 MPa and leak-free performance under high-pressure conditions. Optional features like bellows seals or extended stems enhance safety in hazardous or high-temperature applications.

The pipeline isolation valve is designed for minimal pressure drop and unobstructed flow when fully open, making it ideal for systems requiring maximum throughput. Its corrosion resistant gate valve properties are enhanced by coatings such as epoxy or 3LPE, protecting against aggressive media like seawater, acids, or slurries. The valve’s robust bonnet (bolted or pressure-sealed) withstands thermal cycling and vibration, while non-rising or rising stem options (OS&Y) offer flexibility for manual or actuated operation. With a cycle life exceeding 10,000 operations, it ensures low maintenance and extended service in demanding industrial gate valve applications.

Compared to ball or butterfly valves, the gate valve excels in applications requiring infrequent operation and complete flow isolation, offering lower leakage rates and higher durability under pressure surges. Its ability to handle high-viscosity fluids and abrasive media without clogging makes it superior for slurry pipelines or crude oil systems. Customizable features like gear operators, pneumatic actuators, or API 6D compliance for pipeline service ensure versatility across oil and gas transmission, steam systems, and HVAC networks. The valve’s full-bore design minimizes turbulence, reducing wear on downstream equipment and extending system life.

Addressing challenges like pipeline corrosion, leakage, and thermal stress, the wedge gate valve incorporates double-disc or parallel-slide configurations for enhanced sealing and reduced stem thrust. Its compatibility with global flange standards (ANSI, DIN, JIS) and certifications like SIL 3 for safety-critical systems ensures broad applicability. Whether isolating high-pressure steam in boilers or controlling flow in offshore platforms, the Gate Valve delivers reliable, low-maintenance pipeline isolation valve performance, ensuring safety and efficiency in critical industrial operations.

| Aspect | Description |

|---|---|

| Low Fluid Resistance | Straight-through body design allows fluid to pass with minimal resistance when fully open. |

| Superior Sealing | Provides better sealing performance than shut-off valves, ensuring reliable shutoff. |

| Wide Application Range | Suitable for steam, oil, granular solids, high viscosity media, venting, and low vacuum systems. |

| Bidirectional Flow | Allows flow in both directions, making it suitable for pipelines where flow direction changes. |

| Aspect | Description |

|---|---|

| Slow Operation | The gate must travel a long distance to open or close, leading to longer actuation time. |

| Not for Rapid Actuation | Unsuitable for applications requiring quick shutoff or frequent operation. |

| Surface Damage Risk | Friction between the gate and seat may cause scratches on the sealing surface. |

| Reduced Sealing Performance | Scratches eventually impair sealing efficiency and shorten service life. |

| Repair Difficulty | Damaged sealing surfaces are difficult to repair, though valves are easy to replace. |

Engineered for reliable pipeline isolation with corrosion-resistant materials and robust design.

Gate valves have a simple design, widely used in low pressure-drop services. Their full-port design ensures unobstructed flow and no pressure drop, while also allowing pipeline cleaning with a pigging system.

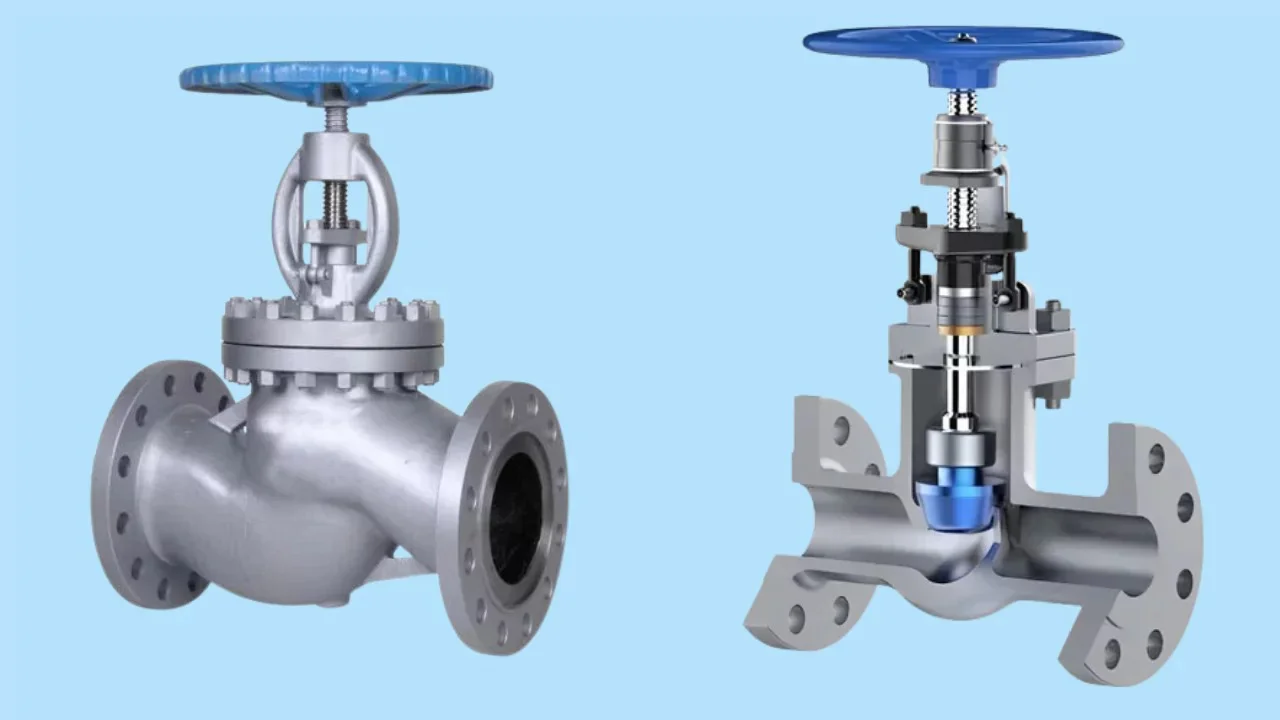

A resilient seated gate valve with a non-rising spindle consists of the following parts. The body is the largest element of the valve, with the bonnet bolted for cleaning and maintenance. The wedge slides down to press the valve seat for complete shutoff and moves upward to allow flow. Over the last century, the construction has remained consistent, with improvements in service life, sealing performance, and corrosion resistance.

Modern gate valve bodies are more compact and sleek, enabling installation in limited space conditions while maintaining durability and efficiency.

Moves vertically to open or close, sealing against the seat for shutoff.

Made of ductile iron, it is the main housing that contains the fluid flow.

Ensures tight sealing when the wedge presses against it.

Transfers rotational motion to vertical movement of the wedge.

Supports the stem to reduce wear during operation.

Bolted to the body for easy cleaning and maintenance access.

Provides sealing around the stem to prevent leakage.

| Organization | Standard | Description |

|---|---|---|

| ANSI | American National Standards Institute | General industrial standards |

| API | American Petroleum Institute | Standards for oil and gas industry |

| ASME | American Society of Mechanical Engineers | Boiler and pressure vessel codes |

| BS | British Standards | UK national standards |

| GB, JB, HG | China Valve Standards | Chinese national and industry standards |

Upstream, midstream, and downstream operations, including drilling, refining, and transportation.

Handling corrosive and hazardous chemicals in various chemical plants.

Steam, water, and fuel systems in thermal, nuclear, and hydroelectric plants.

Municipal water supply, wastewater treatment, and industrial water management.

Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Sterile and hygienic applications, precise flow control in sensitive industries.

Globe valves provide excellent throttling capabili...

A check valve is a mechanical device that allows t...

A ball valve is a shut-off valve that allows, obst...

Butterfly valves for heat exchangers and hvac syst...

The control valve provides precise flow regulation...

The cryogenic valve ensures reliable flow control ...