Api 602 forged globe valves are designed for high pressure and temperature applications in the oil, gas, and petrochemical industries.

Api 602 forged globe valves are designed for high pressure and temperature applications in the oil, gas, and petrochemical industries.

Our valves are designed and manufactured according to international standards, providing reliable service across industries such as oil & gas, chemical, power generation, and pulp & paper.

Our gate valves are industry-approved for a wide range of applications, from oil & gas to pulp & paper.

Inspection and approval norms:

API 602 forged globe valves are engineered to meet the stringent requirements of the petroleum, natural gas, and petrochemical industries. They ensure reliable performance under high pressure and temperature conditions.

Oil and gas production, refining, chemical processing, and power generation.

Typically carbon steel, stainless steel, and alloy steel with forged construction for superior strength.

The API 602 Forged Globe Valve is a compact, high-performance valve engineered for precise flow regulation and reliable shutoff in demanding high-pressure pipeline applications, ideal for oil, gas, water, and chemical systems. Conforming to API 602 standards for forged steel valves, this Forged Globe Valve features a seamless forged body and disc-plug mechanism, providing superior throttling capabilities and tight sealing for pressures up to 2500LB (PN420) and temperatures to 425°C. Constructed from premium forged materials like ASTM A105 carbon steel or A182 F316 stainless steel, it ensures exceptional corrosion resistance with optional coatings such as epoxy or 3LPE, making it suitable for refineries, petrochemical plants, power generation, and water treatment facilities.

Precision-forged through hot working and heat treatment processes, the High Pressure Globe Valve undergoes 100% non-destructive testing (RT, UT, MT, PT) to meet ASME B16.34 pressure-temperature ratings. Available in sizes from 1/4" to 4" (DN8 to DN100) with threaded (NPT), socket weld, or flanged ends per ASME B16.11/B16.5, it supports manual handwheel or actuated operation with an outside screw and yoke (OS&Y) rising stem for clear position indication. The disc-plug, often hard-faced with Stellite #6, ensures abrasion resistance and bidirectional sealing, achieving Class VI shutoff per API 598. Hydrostatic shell tests at 1.5x rated pressure confirm tensile strengths above 485 MPa, ensuring durability under cyclic loading and thermal stress.

The Corrosion Resistant Globe Valve excels in throttling applications, offering precise flow control with minimal cavitation compared to gate or ball valves, thanks to its globe-shaped body that increases flow resistance for better regulation. Enhanced with NACE MR0175 compliance for sour service, it resists H2S and chlorides in aggressive environments like offshore platforms or chemical processing. Optional features like bellows seals or pressure-seal bonnets enhance safety in high-temperature or hazardous applications, while the compact design reduces weight by up to 50% compared to cast valves. Face-to-face dimensions align with ASME B16.10 and BS EN 558 for seamless integration.

Compared to cast globe valves, the API 602 Globe Valve provides superior leak-proof integrity due to forging, which eliminates casting defects, offering 3-5 times longer service life in high-pressure, corrosive environments. It outperforms ball valves in throttling precision, with customizable trim options like equal percentage or linear characteristics for Cv values up to 5,000. Ideal for small-diameter pipelines requiring frequent adjustments, it suits steam, condensate, or viscous media in power generation or water management. Compliance with API 6FA for fire safety and SIL 3 for critical systems ensures reliability in demanding conditions.

Addressing challenges like pipeline corrosion, cavitation in throttling, and leakage under high pressures, the Industrial Flow Control Valve incorporates secondary seals and low-emission packing for enhanced safety. Its value-engineered forged construction balances performance and cost, reducing maintenance in long-term projects. Whether regulating flow in steam boilers or isolating chemical lines, the API 602 Forged Globe Valve delivers precise, reliable High Pressure Globe Valve solutions for global industrial needs.

Globe valves manage water flow in a pipeline through a movable plug/disc-type element and a stationary ring seat in a spherical body. The plug is connected to a stem that operates through a screw action.

Here is a quick-reference globe valve diagram for easy understanding:

There are three basic globe valve body designs: Tee, Angle, and Wye. Each design has unique characteristics, advantages, and applications.

Primarily, when people talk about the type of globe valve, they mean the body style.

The classic and most common globe valve design. The seat is placed horizontally, and the stem moves vertically to the flow.

The ends are set at a 90° angle, requiring fluid to make a single turn. Useful for flows that pulse or surge.

The seat and stem are set at a 45° angle, providing a straighter flow path and reducing pressure drop.

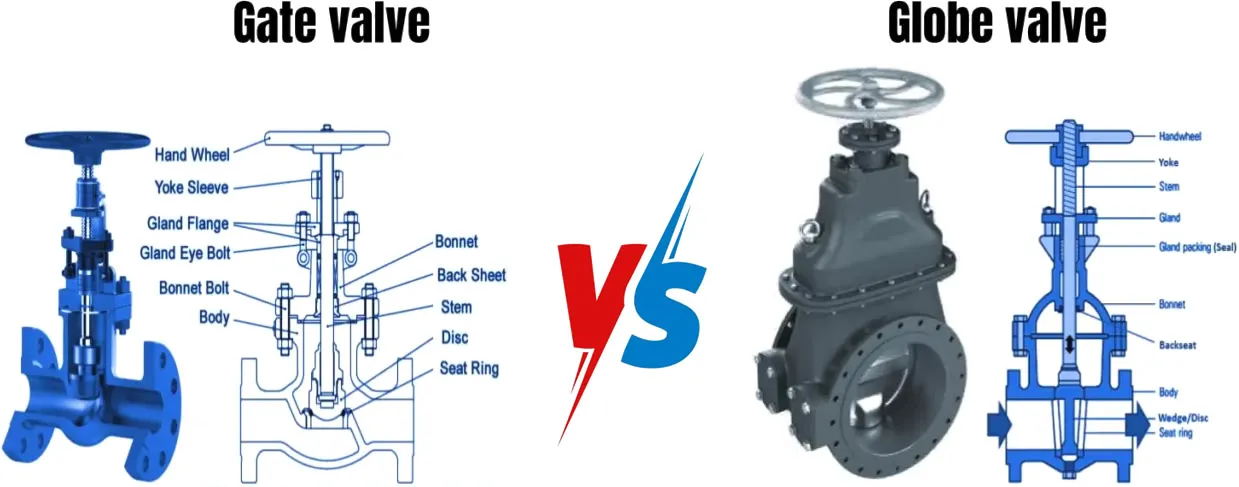

Globe valves and Gate valves are among the most common valves used in industrial plants. Both are engineered to keep systems running efficiently and safely, but their unique designs make them suitable for different applications.

| Aspect | Globe Valve | Gate Valve |

|---|---|---|

| Design | Parts are located inside the cavity, with a rising stem that allows flow changes but also contributes to higher pressure drop. | Simpler construction, most internal components are in the upper part of the body. Provides little pressure drop when open. |

| Flow Control | Excellent for throttling and regulating flow. | Designed mainly for on/off service, not ideal for throttling. |

| Pressure Drop | Higher pressure drop due to changes in flow direction. | Low pressure drop when fully open, straight-through flow path. |

| Applications | Used in applications requiring frequent operation and precise flow control. | Common in pipelines for isolation service, where the valve is fully open or closed. |

| Operation Speed | Slower operation due to shorter stem travel. | Faster operation with longer stem travel to open/close fully. |

| Durability | Better suited for throttling but may wear faster under high-pressure drops. | Longer service life when used in fully open or closed positions. |

| Functions | Primarily used as a control valve. | Designed for media isolation, not for flow control. |

| Working | The disc moves parallel to media flow, requiring minimal lift for full flow. | The disc moves at a right angle to the flow, providing either full flow or zero flow. |

| Organization | Standard | Description |

|---|---|---|

| ANSI | American National Standards Institute | General industrial standards |

| API | American Petroleum Institute | Standards for oil and gas industry |

| ASME | American Society of Mechanical Engineers | Boiler and pressure vessel codes |

| BS | British Standards | UK national standards |

| GB, JB, HG | China Valve Standards | Chinese national and industry standards |

Upstream, midstream, and downstream operations, including drilling, refining, and transportation.

Handling corrosive and hazardous chemicals in various chemical plants.

Steam, water, and fuel systems in thermal, nuclear, and hydroelectric plants.

Municipal water supply, wastewater treatment, and industrial water management.

Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Sterile and hygienic applications, precise flow control in sensitive industries.

A pressure seal is a valve design concept that off...