Stainless steel tube

Seamless And Welded Solutions For Heat Exchange And Fluid Transport

Stainless steel tube is a cylindrical hollow structure made of stainless steel, which is a steel alloy containing a high percentage of chromium.

Seamless And Welded Solutions For Heat Exchange And Fluid Transport

Stainless steel tube is a cylindrical hollow structure made of stainless steel, which is a steel alloy containing a high percentage of chromium.

Stainless steel tubes are widely used in fluid transportation, structural applications, and industrial equipment due to their strength, corrosion resistance, and versatility.

Stainless steel tube is a hollow steel bar widely used for conveying fluids such as oil, gas, water, steam, and in heat exchangers and mechanical systems.

It offers strong bending and torsional resistance while being lightweight, making it ideal for manufacturing mechanical parts, engineering structures, and even military equipment like barrels and shells.

Stainless steel tubes are available in different sizes, wall thicknesses, and lengths to meet specific project requirements.

Stainless steel tubes are widely used in various industries due to their durability, corrosion resistance, and aesthetic appeal. Below are the most common ASTM standards for stainless steel tubing:

| Standard | Description |

|---|---|

| A213 | Seamless stainless steel boiler, superheater, and heat-exchanger tubes |

| A249 | Welded stainless steel boiler, superheater, heat exchanger, and condenser tubes |

| A268 | Seamless and welded stainless steel tubing for general service |

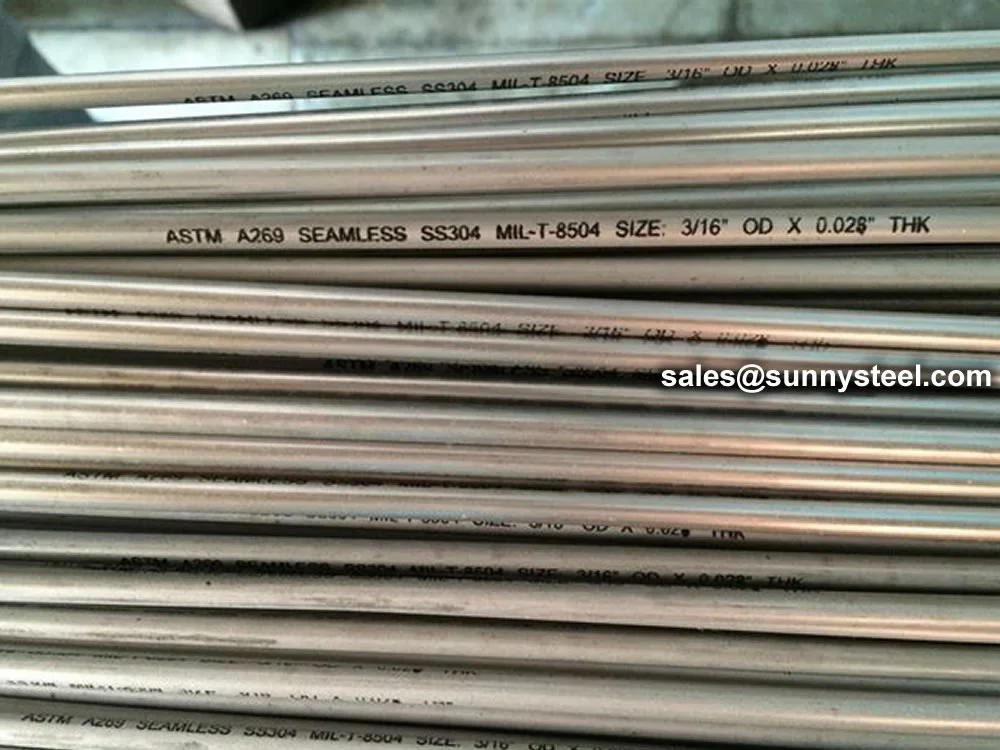

| A269 | Seamless and welded austenitic stainless steel tubing for general service |

| A270 | Seamless and welded stainless steel sanitary tubing |

| A688 | Welded austenitic stainless steel feedwater heater tubes |

| A789 | Seamless and welded stainless steel tubing for general service |

Fluid transport and pipelines

Structural support & architecture

Exhaust systems & components

Pipelines & process systems

Thermal energy transfer

Sanitary and clean systems

Stainless Steel Tubes are precision-engineered for fluid transport, heat exchange, and structural applications in demanding industrial environments. Compliant with ASTM A213 for seamless boiler and heat-exchanger tubes, ASTM A269 for general service tubing, and ASTM A312 for larger welded tubes, these products offer superior corrosion resistance and durability. Grades like TP304/304L provide cost-effective performance for general use, while TP316/316L excels in chloride-rich environments, such as marine or chemical processing, due to enhanced pitting resistance. Seamless Stainless Tubes, produced via extrusion or rotary piercing, ensure integrity for high-pressure systems up to 4500 psi, while Welded Stainless Tubes, formed from strip welding, offer cost-efficiency for larger diameters and lower-pressure applications.

These Corrosion Resistant Tubes deliver exceptional mechanical properties, with tensile strengths ≥515 MPa, yield strengths ≥205 MPa, and elongations up to 40%, enabling bending, flaring, and welding. Chromium (18-20%) forms a self-healing oxide layer, enhanced by nickel (8-14%) for ductility and molybdenum (in 316) for pitting resistance. Available in sizes from 1/8" to 12" (DN6 to DN300) and wall thicknesses from 0.010" to 0.5" (SCH 5S to SCH 80S), they suit applications like heat exchangers, sanitary systems, and chemical processing. Surface finishes like polished or electropolished meet stringent hygiene standards for pharmaceuticals, while heat treatments ensure performance in cryogenic conditions down to -196°C.

Seamless Stainless Tubes are ideal for high-pressure heat exchangers under ASME SA213, offering zero weld imperfections for critical applications like power generation. Welded Stainless Tubes provide cost savings of up to 20% for low-to-medium pressure systems, such as food processing or HVAC, with scalability for larger diameters. Benefits include a lifespan of up to 50 years and 30-40% lower lifecycle costs compared to carbon steel due to minimal maintenance. Custom options like cut-to-length or beveled ends support integration into medical gas lines, aerospace components, or offshore platforms. NACE MR0175 compliance ensures reliability in sour service environments.

Compared to carbon steel, Stainless Steel Tubes offer 2-3 times better corrosion resistance, eliminating frequent maintenance in acidic or seawater conditions. Unlike plastic tubes, they withstand extreme temperatures (up to 650°C) and pressures, ensuring safety in industrial flows. Long-tail keywords like “seamless stainless steel tube for heat exchangers” or “welded stainless tube for sanitary systems” align with ASTM and NSF 61 standards. Rigorous testing—tensile, flattening, and hydrostatic—ensures compliance, with duplex grades like 2205 available for enhanced strength in aggressive conditions.

Addressing challenges like erosion in high-velocity flows and biofouling in water systems, these Industrial Stainless Tubes incorporate alloy enhancements like nitrogen for improved pitting resistance. Their 100% recyclability aligns with eco-friendly regulations, making them a sustainable choice. Whether used in heat exchangers for power plants or sanitary tubing for food processing, Stainless Steel Tubes deliver unmatched strength, versatility, and performance for global industrial demands.

Engineered for robust fluid transport and heat exchange with superior corrosion resistance.

Reduced surface area minimizes painting, fireproofing, and labor costs.

High weight-to-strength ratio ensures durability and reliability in use.

Used in construction, structural engineering, and various industrial projects.

We stock a wide range of schedules to ensure the right choice for every application, from low-pressure systems to the most demanding industrial conditions.

Lightweight and cost-effective, ideal for low-pressure applications such as water distribution, fire protection systems, and HVAC ductwork.

Stronger than Schedule 10, commonly used in residential plumbing, industrial cooling, and chemical applications.

Designed for high-pressure environments, offering improved durability for industrial processes and oil & gas applications.

Exceptional strength for extreme pressure and temperature conditions. Ideal for power plants, petrochemical industries, and steam lines.

The thickest and most robust pipe schedule, built for the most demanding industrial conditions like deep well drilling and high-pressure hydraulics.

We offer both welded and seamless stainless steel pipes in a range of configurations to meet your specific needs.

Welded pipes are manufactured by bending a sheet of steel into a tube and welding the seam.

Seamless pipes are created by heating a solid billet and piercing it with a mandrel to form a tube.

| Aspect | Seamless Pipes | Welded Pipes |

|---|---|---|

| Strength | Higher strength, no weld seam | Lower strength due to weld seam (but improving with technology) |

| Cost | Generally more expensive | More cost-effective to manufacture |

| Usage | High-pressure applications | Low to medium pressure applications |

| Availability | Smaller sizes, limited larger sizes | Wide range of sizes and lengths available |

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Stainless steel tube ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Stainless steel tube suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

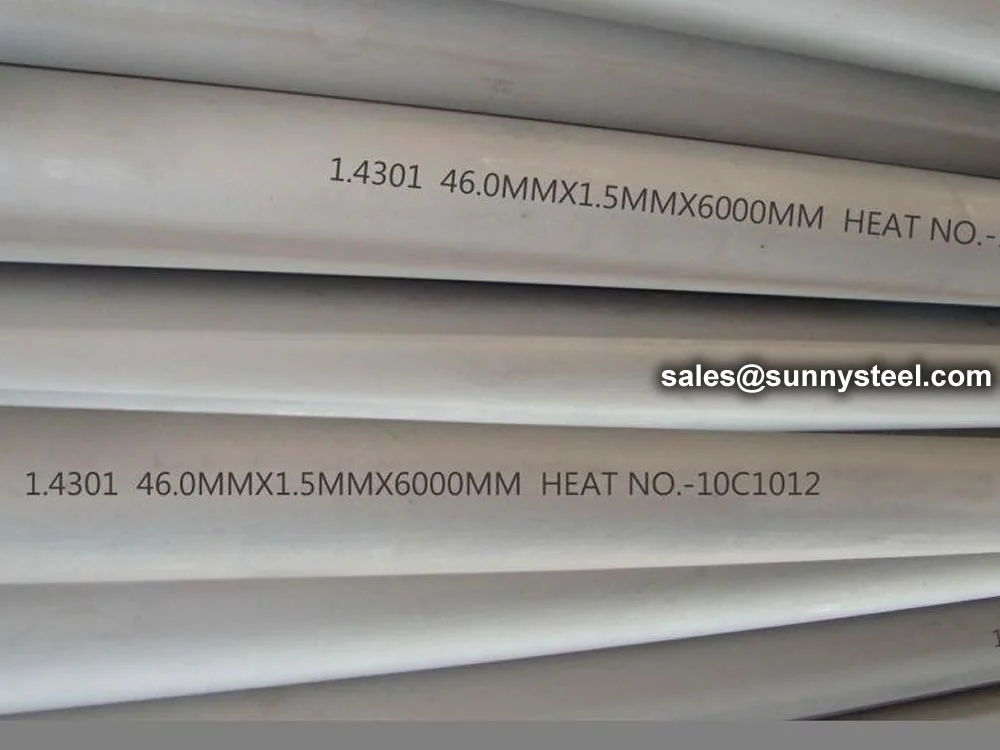

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

Stainless steel pipe is one of the more standardiz...

Austenitic stainless steel is a type of stainless ...