Stainless steel welded pipes / tubes are made from the finest materials and are designed for industrial use.

Stainless steel welded pipes / tubes are made from the finest materials and are designed for industrial use.

Stainless steel welded pipes are manufactured by welding a steel plate or strip to form a pipe.

The process ensures precision, uniformity, and high-quality finishes, making them ideal for both structural and fluid transport applications. These pipes are available in various grades and dimensions, tailored to meet the specific requirements of diverse industries.

Stainless Steel Welded Pipes are engineered for cost-effective fluid transport and structural applications in demanding industrial environments. Compliant with ASTM A312 for welded austenitic stainless steel pipes and API 5L for oil and gas pipelines, these pipes offer excellent corrosion resistance and durability for low-to-medium pressure systems. Grades like TP304/304L provide cost-effective performance for general use, while TP316/316L excels in chloride-rich environments, such as chemical processing or marine applications, due to superior pitting resistance. Manufactured by longitudinal or spiral welding of stainless steel strips, Welded Stainless Pipes deliver scalability for large diameters, making them ideal for water distribution, HVAC, and food-grade systems.

These Corrosion Resistant Welded Pipes feature tensile strengths ≥515 MPa, yield strengths ≥205 MPa, and elongations up to 40%, enabling welding, bending, and flanging without compromising integrity. Chromium (18-20%) forms a self-healing oxide layer, enhanced by nickel (8-14%) for ductility and molybdenum (in 316) for pitting resistance. Available in sizes from 1/8" to 36" (DN6 to DN900) and wall thicknesses from SCH 5S to SCH 80S, they suit diverse applications. Surface finishes like pickled, polished, or electropolished meet sanitary standards for pharmaceuticals and food processing, while heat treatments ensure performance in temperatures from -196°C to 650°C. NACE MR0175 compliance supports sour service in oil and gas pipelines.

Compared to seamless pipes, Welded Stainless Pipes offer up to 20% cost savings, making them ideal for large-scale projects like water treatment or architectural structures. They perform reliably in low-to-medium pressure systems (up to 1500 psi), with welded joints tested via radiographic or ultrasonic methods to ensure integrity per ASTM A312. Benefits include a lifespan of up to 50 years and 30-40% lower lifecycle costs compared to carbon steel due to minimal maintenance. Custom options like cut-to-length, beveled ends, or specific weld seam finishes support integration into refineries, chemical plants, or municipal water systems.

Unlike carbon steel, Stainless Steel Welded Pipes provide 2-3 times better corrosion resistance, eliminating frequent painting in acidic or seawater environments. Compared to plastic pipes, they handle higher temperatures and pressures, ensuring safety in industrial flows. Long-tail keywords like “welded stainless steel pipe for chemical processing” or “ASTM A312 welded pipe for sanitary systems” align with NSF 61 and ASME BPE standards. Rigorous testing—tensile, flattening, and hydrostatic—ensures compliance, with duplex grades like 2205 available for enhanced strength in aggressive conditions.

Addressing challenges like biofouling in water systems and erosion in high-velocity flows, these Industrial Welded Pipes incorporate alloy enhancements like nitrogen for improved pitting resistance. Their 100% recyclability aligns with eco-friendly regulations, making them a sustainable choice. Whether transporting potable water, chemicals, or gases, Stainless Steel Welded Pipes deliver unmatched cost-efficiency, durability, and performance for global industrial demands.

Stainless steel welded pipes are indispensable in modern engineering and industry. Their unmatched combination of strength, durability, and corrosion resistance makes them ideal for diverse applications, from skyscraper construction to pipeline systems.

Duplex welded stainless steel pipes are widely used in:

Key advantages include superior corrosion resistance (pitting, crevice, abrasion), excellent weldability, strong mechanical properties, and cost-effectiveness.

| NPS | 1/8" through 24" |

|---|---|

| Schedules | 5, 10, 10S, 20, 30, 40, 40S, 80, 80S |

| Material Grades | Various stainless steel grades (customizable) |

| Standards | ASTM A312, ASME SA312 |

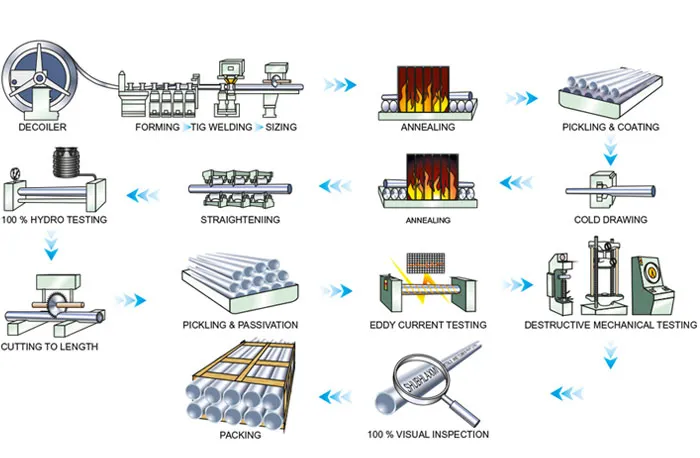

A step-by-step overview of how high-quality stainless steel welded pipes are produced for industrial and structural applications.

High-quality stainless steel is chosen according to the specific requirements of the application.

Steel strips are rolled into a circular shape to prepare for welding.

Edges are welded using advanced techniques like TIG (Tungsten Inert Gas) welding for a precise seam.

Pipes undergo heat treatment to enhance mechanical properties and ensure durability.

Polishing removes impurities, resulting in a smooth and aesthetically appealing surface.

Each pipe is tested for strength, durability, and corrosion resistance to ensure top quality.

Engineered for cost-effective fluid transport with superior corrosion resistance.

Heat resisting stainless steel pipes are premium a...

A seamless stainless steel pipe is a metal tube ma...

Stainless steel oval pipes deliver superior corros...

Stainless steel pipes for oil cracking provide sup...