Industrial austenitic stainless steel pipes offer superior corrosion resistance and durability for boiler pipeline protection and high-temperature applications.

Industrial austenitic stainless steel pipes offer superior corrosion resistance and durability for boiler pipeline protection and high-temperature applications.

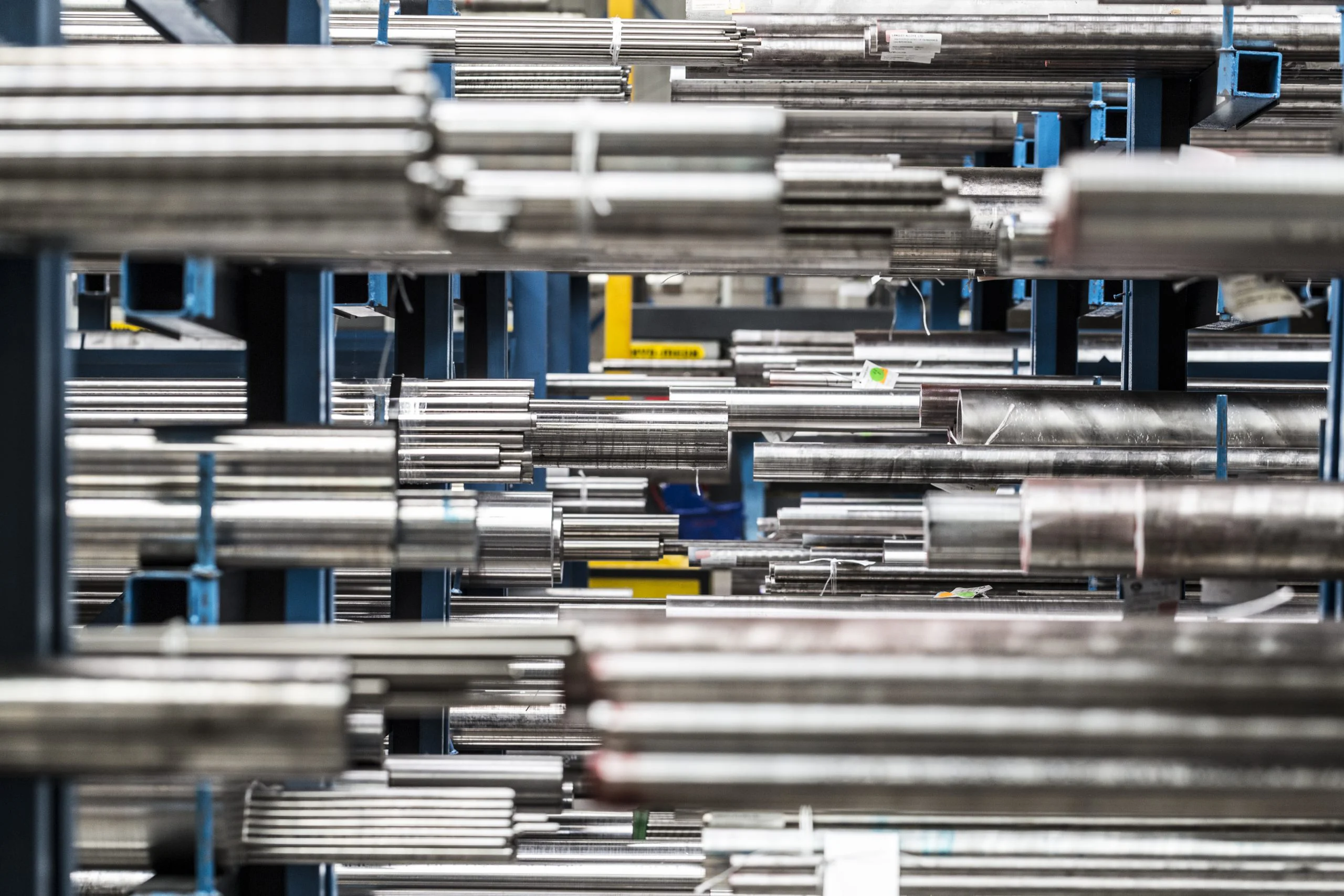

Austenitic stainless steel pipes represent the most versatile stainless steel family, valued for their exceptional corrosion resistant industrial tubes and fabrication ease in rigorous industrial settings. Featuring a face-centered cubic structure stabilized by nickel (typically 8-25%) and chromium (16-26%), these alloys effectively resist rust, pitting, and stress corrosion cracking, rendering them essential for boiler pipeline protection amid constant exposure to steam, flue gases, and acidic condensates. Standard grades including 304, 316, and 321 adhere to ASTM A312, A213, and ASME SA312 specifications, available in seamless or welded forms that manage pressures up to 20 MPa and temperatures from cryogenic to 800°C, guaranteeing enduring reliability in power plants, refineries, and chemical facilities.

Produced via hot extrusion, cold drawing, or electric resistance welding, followed by solution annealing at 1010-1120°C, austenitic stainless steel pipes attain superior ductility and non-magnetic characteristics. Low-carbon options like 304L and 316L limit carbide formation, enhancing weldability without post-heat treatment, whereas stabilized variants such as 321 (with titanium) prevent intergranular corrosion in the 425-815°C sensitization zone. Offered in schedules from SCH 5S to SCH 160, with outer diameters spanning 1/8" to 24" (6-610mm) and lengths up to 12m or coiled, these pipes facilitate U-bending, flanging, and threading for effortless incorporation into shell-and-tube heat exchangers and elevated-pressure high temperature austenitic piping networks.

For boiler pipeline protection, austenitic stainless steel pipes such as 304 serve as an economical safeguard against erosion from high-velocity ash flows and oxidation in sulfur-laden atmospheres. Comprehensive testing, encompassing hydrostatic (up to 10 MPa), eddy current, and flattening procedures, confirms adherence, yielding tensile strengths of 515-690 MPa and elongations of 40%. Finishes vary from mill annealed to electropolished (Ra < 0.4 μm) for hygienic uses in food processing, with supplementary coatings like PTFE linings providing extra chemical safeguards for abrasive slurry conveyance in mining.

In contrast to ferritic or martensitic counterparts, corrosion resistant industrial tubes demonstrate enhanced formability—permitting up to 50% cold reduction—and cryogenic toughness to -196°C, suiting LNG transport. Duplex hybrids like 2205 deliver elevated strength for lightweight demands, while the non-hardenable austenitic matrix enables expansion joints and bellows compliant with ASME B31.3. Their recyclability (up to 90%) supports sustainable practices in renewable energy initiatives. This versatility underpins the creation of elbows, tees, and reducers per ASTM A403, promoting compatibility in intricate desalination and pulp mill networks.

By mitigating persistent issues like chloride stress cracking in coastal refineries or caustic embrittlement in alkaline boilers, these pipes prolong service life 3-5 times beyond carbon steel, cutting replacement expenses and bolstering safety in line with NACE SP0177. Whether applied for boiler tube erosion protection in biomass facilities or as general stainless steel corrosion shields in wastewater systems, austenitic stainless steel pipes establish a sturdy, economical base for resilient industrial setups, affirmed by extensive global adoption.

Super austenitic stainless steel refers to chromium-nickel (Cr-Ni) stainless steel with a Pitting Resistance Equivalent Number (PREN = [Cr] + 3.3[Mo] + 16[N]) of ≥40%. In highly corrosive media containing chloride ions (Cl⁻), it demonstrates better resistance to chloride pitting and crevice corrosion compared to Cr-Ni austenitic stainless steel with molybdenum (Mo) content greater than 4%.

| Grade | C | Mn | Si | P | S | Cr | Ni | Others |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | N: 0.10 |

| 316 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | Mo: 2.0-3.0 |

| 321 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | Ti: 5xC min |

| 310S | 0.08 | 2.00 | 1.50 | 0.045 | 0.030 | 24.0-26.0 | 19.0-22.0 | - |

Super austenitic stainless steels contain high lev...