Corrosion-resistant Tubing

Stainless steel oval pipes deliver superior corrosion resistance and structural strength for industrial and decorative applications, protecting against erosion in boiler pipelines and harsh environments.

Corrosion-resistant Tubing

Stainless steel oval pipes deliver superior corrosion resistance and structural strength for industrial and decorative applications, protecting against erosion in boiler pipelines and harsh environments.

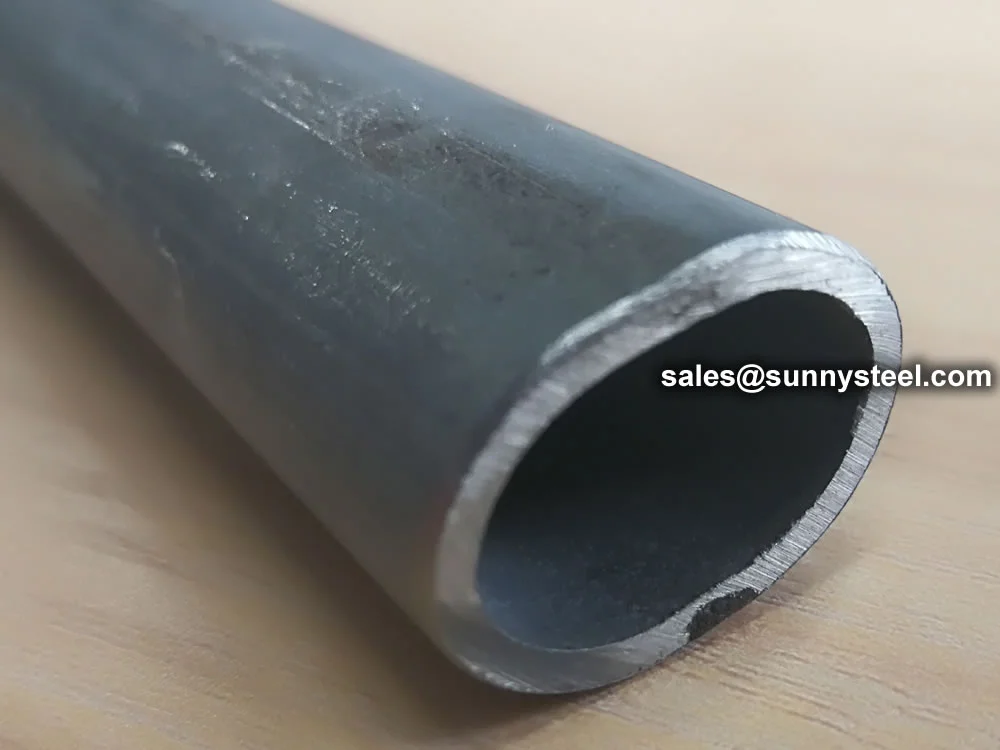

Stainless steel oval pipes are specialized, non-round tubing profiles engineered for enhanced structural performance and aesthetic versatility in industrial and architectural applications, providing robust corrosion resistant oval tubes against environmental degradation. Formed from austenitic grades like 304, 316, and 304L through cold rolling or extrusion, these pipes feature elliptical cross-sections that optimize space utilization and load distribution, conforming to ASTM A554 and A312 standards for welded and seamless constructions. With high chromium (18-20%) and nickel (8-10%) content, they form a passive oxide layer that excels in resisting pitting, crevice corrosion, and atmospheric oxidation, making them ideal for boiler pipe erosion protection where irregular shapes accommodate tight bends in heat exchangers and exhaust systems without compromising flow efficiency.

The oval configuration—typically with major axes of 20-200mm and minor axes of 10-100mm—enhances torsional rigidity by 20-30% over round equivalents, while maintaining weldability via TIG or ERW processes without filler metals in many cases, ensuring seamless integration in oval stainless steel piping networks. Low-carbon variants like 304L minimize sensitization risks during annealing at 1010-1120°C, preventing intergranular attack in the 425-815°C range, whereas 316 grades with molybdenum additions boost resistance to chloride-induced pitting in marine or chemical exposures. Available in wall thicknesses from 0.5-6mm and lengths up to 12m, these pipes support custom polishing (Ra < 0.8 μm) and bending radii as tight as 3D, facilitating fabrication into handrails, furniture frames, and industrial oval tubing for automotive mufflers where vibration damping and erosion resistance are paramount.

In boiler pipe erosion protection, stainless steel oval pipes mitigate wear from high-velocity particulates and thermal cycling, with rigorous testing including hydrostatic (up to 10 MPa), flattening, and reverse bend confirming compliance and delivering tensile strengths of 515-620 MPa with elongations over 40%. Surface treatments range from mill finish to mirror-polished, with optional internal linings like PTFE for chemical resistance in slurry transport, while their non-magnetic properties (permeability <1.05) suit electromagnetic-sensitive installations. Compared to carbon steel oval sections, these pipes offer 4-6x longer lifespan in humid or coastal atmospheres, reducing maintenance intervals and aligning with ASME B31.3 for process piping.

Relative to round stainless tubing, corrosion resistant oval tubes provide superior aerodynamic flow in ventilation ducts and architectural facades, with enhanced moment of inertia for beam applications in construction scaffolding. Duplex options like 2205 add higher yield strength (450 MPa) for load-bearing oval stainless steel piping, but austenitic grades dominate for cost-effective formability in decorative railings and furniture. Their recyclability (up to 95%) supports sustainable design, enabling cold forming into complex shapes per ASTM A554 without heat treatment, ensuring compatibility with fittings and clamps in modular industrial oval tubing systems.

Tackling challenges like uneven erosion in curved boiler sections or aesthetic fading in outdoor structures, these pipes extend operational reliability by 50%, minimizing downtime in petrochemical flares and marine railings. For designers seeking boiler pipe erosion protection with custom profiles or versatile corrosion resistant oval tubes for automotive frames, stainless steel oval pipes offer a durable, adaptable choice, proven in diverse global infrastructures for seamless performance and longevity.

| Grade | C | Mn | Si | P | S | Cr | Ni | Others |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | N: 0.10 |

| 316 | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | Mo: 2.0-3.0 |

| 304L | 0.03 | 2.00 | 0.75 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | N: 0.10 |

| 2205 (Duplex) | 0.03 | 2.00 | 1.00 | 0.030 | 0.020 | 22.0-23.0 | 4.5-6.5 | Mo: 3.0-3.5; N: 0.14-0.20 |

Stainless steel oval pipes offer a unique combination of functionality and versatility, with applications across various industries. Here are their key characteristics:

Oval stainless steel tubing provides an excellent solution for ground clearance challenges and tight spaces. Its unique oval shape allows for better maneuverability in areas where traditional round tubing may not fit easily, making it ideal for compact installations and constrained environments.

Leveraging the inherent properties of stainless steel, these oval pipes offer excellent corrosion resistance. This makes them particularly suitable for applications where exposure to moisture, chemicals, or corrosive substances is a concern, ensuring long-term performance in harsh environments.

Constructed from high-quality stainless steel, oval pipes deliver exceptional strength and durability. They can withstand high temperatures, significant pressure, and substantial mechanical stress, making them a reliable choice for demanding industrial and commercial applications.

The distinctive oval shape adds a unique visual element to architectural and decorative designs. These tubes are frequently used in furniture, railings, and various design applications where aesthetics play a key role, combining functionality with an attractive appearance.

Heat resisting stainless steel pipes are premium a...

A seamless stainless steel pipe is a metal tube ma...

Stainless steel pipes for oil cracking provide sup...

Stainless steel welded pipes / tubes are made from...